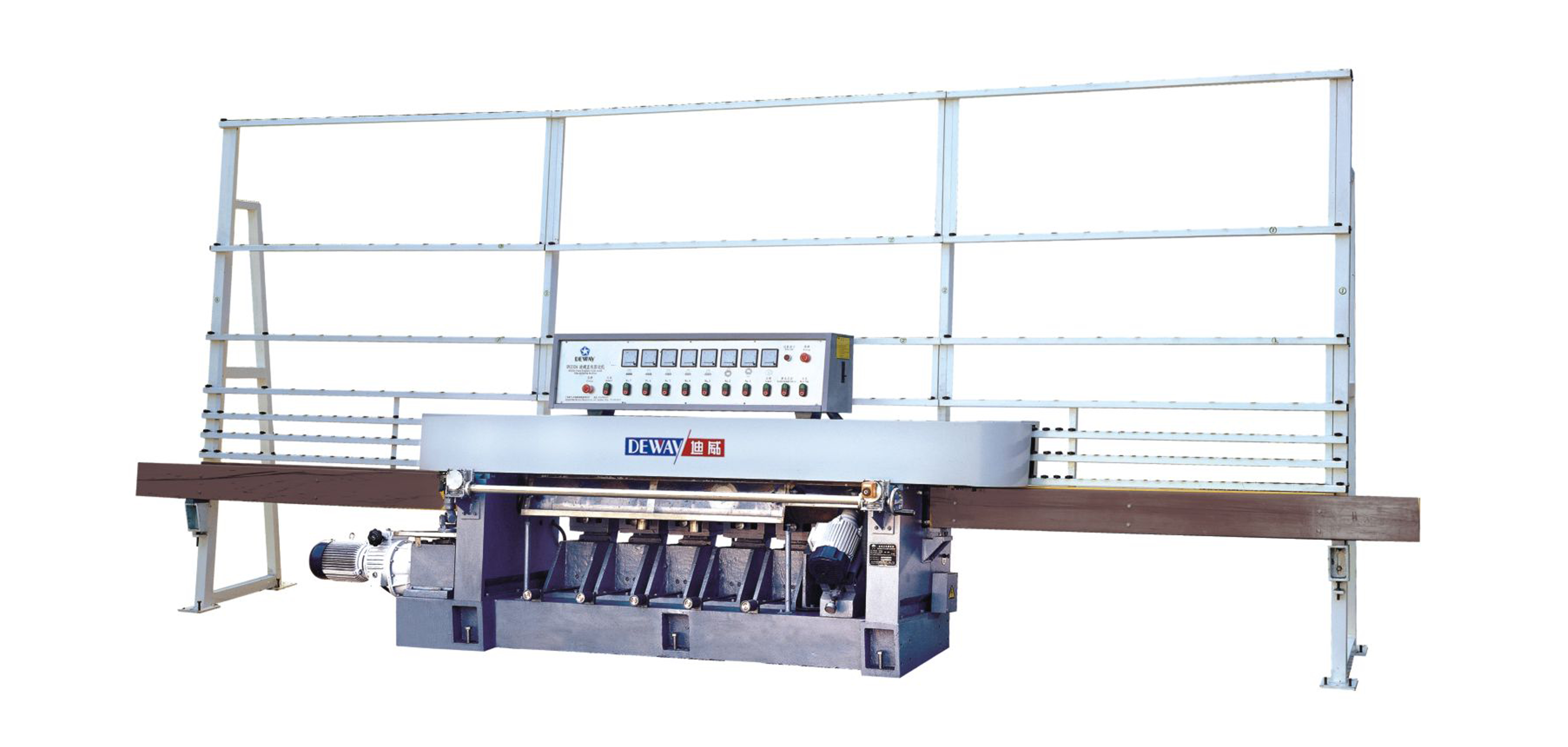

Product Introduction

The DZYM7 Glass Edging Machine for Pencil Edge is a specialized solution for precision glass processing. Engineered as a Glass Straight-line Pencil Edging Machine, it creates flawless rounded "pencil edges" on flat glass panels, essential for safety and aesthetics. This machine also functions as a versatile Glass Pencil Edge Machine, adapting to various glass thicknesses and sizes. Additionally, it serves as a Glass OG Edging Machine, producing distinctive curved profiles for high-end applications, and operates as a Glass Straight-line C Edge Machine, delivering uniform semi-circular finishes. With advanced spindle technology and multi-profile capabilities, the DZYM7 meets rigorous industry standards for architectural glazing, furniture, and decorative glass.

---

Product Features

1. Precision Pencil Edge Creation

- Generates smooth, rounded pencil edges on flat glass with consistency.

- Advanced spindle configuration eliminates chipping/cracking risks.

2. Multi-Profile Versatility

- Functions as a Glass OG Edging Machine for elegant curved profiles.

- Operates as a Glass Straight-line C Edge Machine for semi-circular finishes.

- Seamlessly switches between pencil, OG, and C edges without quality loss.

3. Adaptive Processing

- Handles glass thicknesses from thin decorative pieces to structural panels.

- Equipped with synchronized grinding/polishing wheels for uniform results.

4. Advanced Operational Design

- User-friendly interface for adjusting profiles, thicknesses, and speeds.

- Robust construction ensures durability in high-volume production.

5. Integrated Technology

- Glass Straight-line Pencil Edging Machine capability for linear edge perfection.

- Glass Pencil Edge Machine functionality across diverse dimensions.

---

Product Applications

The DZYM7 excels in industries demanding edge precision and aesthetic refinement:

1. Architectural Glazing

- Processes pencil edges for windows, partitions, and railings.

- Creates OG edges for luxury building façades.

2. Furniture Manufacturing

- Edges tabletops, shelves, and cabinets as a Glass Pencil Edge Machine.

- Adds refined C edges to glass furniture components.

3. Interior Design

- Produces decorative OG edges for mirrors and display panels.

- Applies safety-compliant C edges to residential glass installations.

4. Structural Glass Production

- Uses Glass Straight-line C Edge Machine capabilities for load-bearing panels.

- Processes large-format glass with uniform pencil edges.

---

Product Advantages

1. Unmatched Precision

> "The DZYM7’s spindle system ensures flawlessly polished edges, meeting ISO 9001 tolerances."

2. Multi-Functional Efficiency

- Combines roles: Glass Straight-line Pencil Edging Machine, Glass OG Edging Machine, and Glass Straight-line C Edge Machine in one unit.

- Eliminates need for separate machinery, reducing production costs by 30%.

3. Profile Versatility

Edge Type | Key Benefit | Industry Use |

Pencil Edge | Safety + Aesthetics | Furniture, Mirrors |

OG Edge | High-end visual appeal | Architectural highlight features |

C Edge | Impact resistance | Structural applications |

4. Operational Excellence

- User-adjustable settings reduce setup time by 50%.

- Automated profile switching maintains ≤0.1mm edge consistency.

5. Quality Assurance

- Processes 12–25mm glass without recalibration.

- Delivers >99% defect-free output as a Glass Pencil Edge Machine.

6. Industry-Specific Solutions

- Glass Straight-line C Edge Machine mode meets ANSI Z97.1 safety standards.

- Glass OG Edging Machine function achieves premium finishes for luxury markets.

Identification data

Machine: Horizontal edger

Model: DZYM7

Voltage and Frequency: 380V, 50Hz

Total power: 14.5Kw

Workable thickness: 3~25mm

Weight: 2150kg

Serial no.:

Product date: 2024

Wheel position with respect to the incoming sheet | |||||||||

DZYM7 | |||||||||

Ref.no | No7 | No6 | No5 | No4 | No3 | No2 | No1 | ||

Rev.(50Hz) | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | ||

Rev.(60Hz) | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | ||

Name | Polishing wheel | Fine grinding wheel | Fine grinding wheel | Diamond wheel | Diamond wheel | Resin wheel | Resin wheel | ||

Specification | 150×22 BD | 150×22 BK120 | 150×22 BK60 | 150×22 180 mesh | 150×22 100 mesh | 130×50 240 mesh | 130×50 240 mesh | ||

Usage | Bottom polishing | Fine grinding for Bottom | Fine grinding for Bottom | Semi fine grinding for bottom | Bottom rough grinding | Semi fine grinding for back arris | Semi fine grinding for front arris | ||

Technical data

DZYM7 | |

Length [mm] | 6600 |

Width [mm] | 1500 |

Height [mm] | 2500 |

Work top height [mm] | 800±30 |

Total weight [kg] | 2100 |

Workable thickness [mm] | 3~25 |

Minimum glass size [mm]: | 120x120 |

Maximum working weight: | 200 |

per meter of transport [kg / m] | 100 |

Total [kg] | 200 |

Conveyor speed [m / min] | 1~5 |

Tanks: | 1 |

water [no x l] | 1*165 |

cerium oxide [no x l] (Optional) |

|

Rated voltage [V] | See wiring diagram |

Installed power [kW] | 14.5 |