Brief introduction

DZM vertical straight-line edgers process glass/mirror flat edges using cup diamond and polishing wheels. Manual loading → motorized conveyor feeds sheets at 6° tilt. Operator interaction limited to load/unload. Single operator (optional assistant). Lifting equipment mandatory for sheets >30kg.

Product Introduction

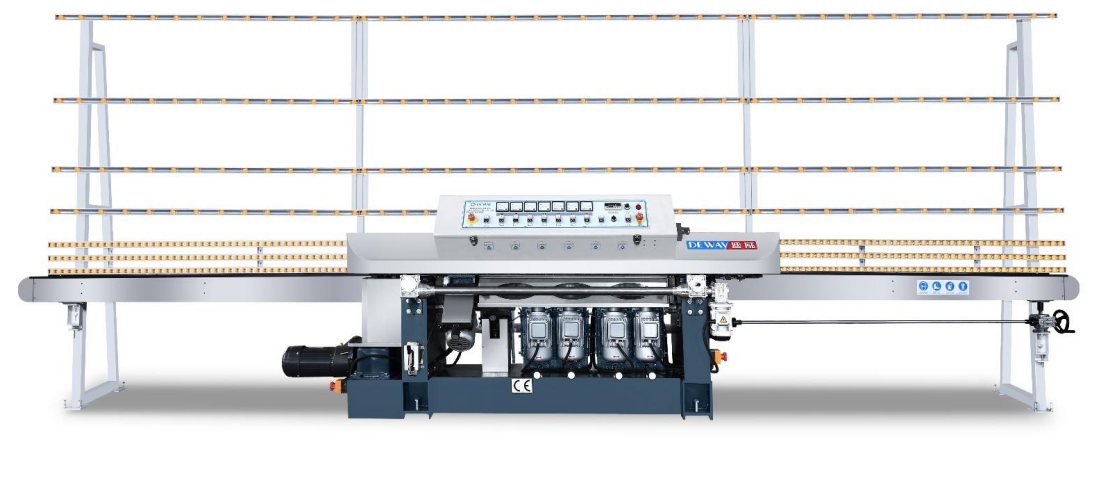

The DZM6 Glass Straight-line Edging Machine is a 6-spindle Glass Processing Machine engineered for precision flat-edge finishing. This Glass Polishing Machine delivers exceptional straight-line polishing results, serving as a vital asset in glass manufacturing facilities.

---

Product Features

Processing System:

- Six high-precision spindles for sequential operations

- Integrated Glass Grinding machine capabilities

- Advanced Glass Flat Edger polishing system

- Robust vibration-resistant construction

Technical Specifications:

- Processes all glass types and thicknesses

- Handles small pieces to large panels

- Compact industrial design

- Minimal operational vibration

Control System:

- Intuitive operation interface

- Real-time processing monitoring

- Adjustable precision settings

---

Product Applications

This Glass Processing Machine serves:

- Glass manufacturing plants

- Custom glass fabrication operations

- Architectural glass panel production

- Decorative glass element creation

- Industrial-scale production facilities

- Small to medium workshop environments

---

Product Advantages

Precision & Quality:

- Produces perfectly straight and smooth edges

- Achieves brilliant glossy finishes

- Ensures dimensional grinding accuracy

- Maintains consistent output quality

Operational Efficiency:

- Single-system grinding and polishing solution

- Minimizes processing errors

- Reduces material waste

- Adapts to straight and complex edges

Durability & Maintenance:

- Wear-resistant and corrosion-resistant components

- Extended machine operational lifespan

- Minimal maintenance requirements

Versatility:

- Handles all glass types and thicknesses

- Processes small pieces to large panels

- Compact multi-environment design

User Benefits:

- Intuitive controls reduce operator training time

- Enhanced production productivity

- Lower operational costs

- Reliable continuous performance

---

Technical Summary

The DZM6 Glass Straight-line Edging Machine exemplifies industrial-grade processing. This premier Glass Flat Edger combines 6-spindle efficiency with precision Glass Grinding machine and polishing capabilities for superior edge finishing.

| Wheel position with respect to the incoming sheet | ||||||

| DZM6 | ||||||

| Ref.no | No6 | No5 | No4 | No3 | No2 | No1 |

| Rev.(50Hz) | 2800 | 2800 | 1400 | 2800 | 2800 | 2800 |

| Rev.(60Hz) | 3360 | 3360 | 1680 | 3360 | 3360 | 3360 |

| Name | resin wheel | resin wheel | polishing wheel | fine grind wheel | resin wheel | diamond wheel |

| Specification | 130×50 240 mesh | 130×50 240 | X5000 150×50 | 10S40 150×70 | 150×12 240mesh | 150×12 100mesh |

| Usage | Semi fine grinding for front arris | Semi fine grinding for back arris | bottom polishing | bottom fine grinding | Semi fine grinding for bottom | bottom rough grinding |

Technical Specification:

DZM6 | |

Length [mm] | 5280 |

Width [mm] | 1200 |

Height [mm] | 2520 |

Work top height [mm] | 800±30 |

Total weight [kg] | 1750 |

Workable thickness [mm] | 4~25 |

Minimum glass size [mm]: | 120x120 |

Maximum working weight: | 200 100 200 |

Conveyor speed [m / min] | 1~5 |

Tanks: | 1 |

water [no x l] | 1*165 |

Rated voltage [V] | See wiring diagram |

Installed power [kW] | 14 |