Product Introduction

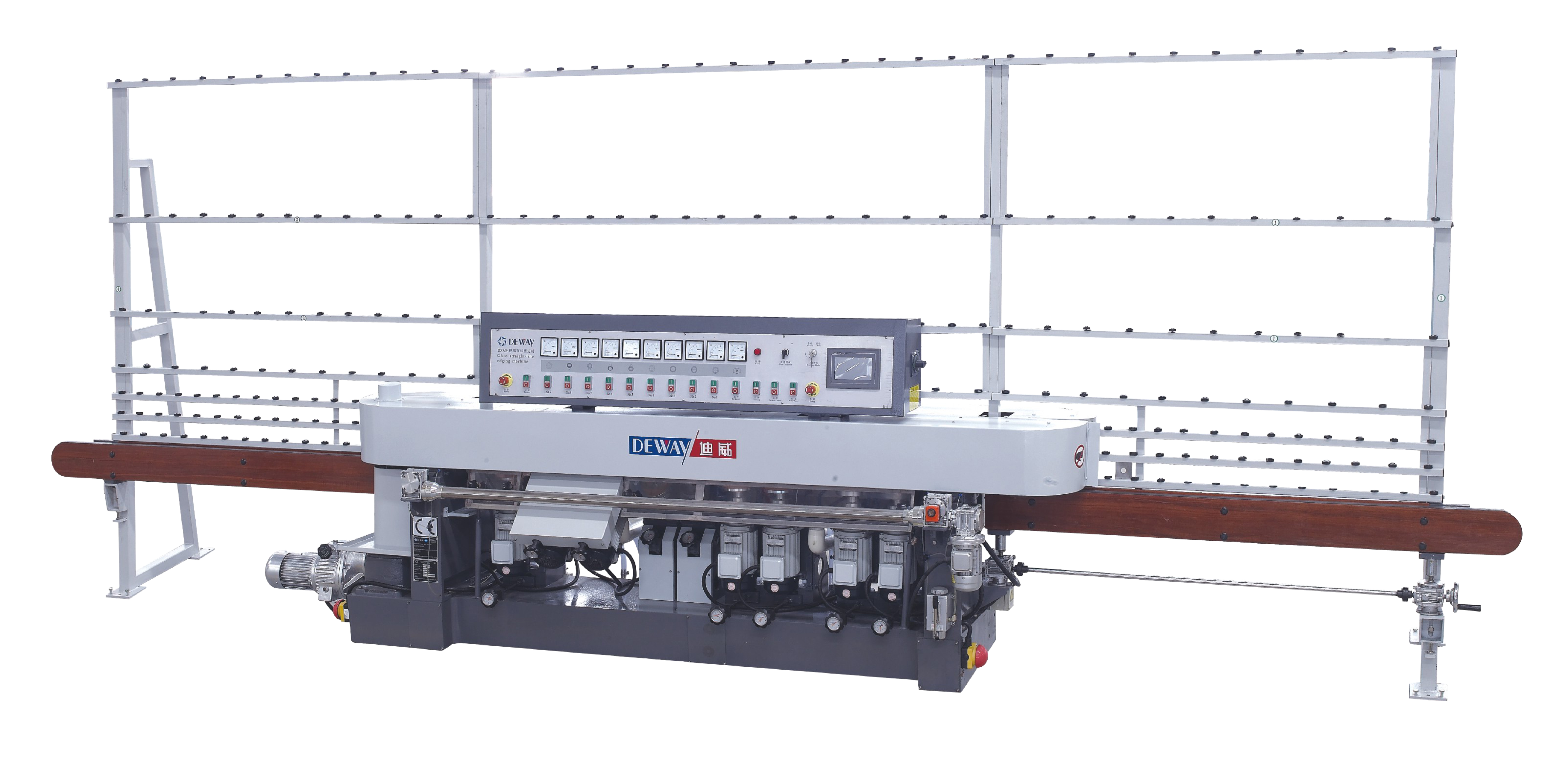

The DZM11 Glass Straight-line Single Edging Machine is an 11-spindle industrial solution for demanding glass processing. This Glass Processing Machine delivers unparalleled precision in straight-line edging, serving as an essential tool for manufacturers requiring excellence in glass finishing.

---

Product Features

Processing System:

- Eleven high-performance spindles for synchronized operations

- Integrated Glass Grinding machines for dimensional preparation

- Advanced Glass edge polishing system for flawless finishes

- Corrosion-resistant construction

Technical Capabilities:

- Handles all glass sizes (small to large)

- Processes wide thickness ranges

- Prepares perfectly straight edges before polishing

- Minimizes material waste during grinding

Control & Operation:

- Intuitive control system for real-time monitoring

- Easy adjustment of processing settings

- Ergonomic operator interface

---

Product Applications

This Glass Processing Machine serves:

- High-end glass finishing applications

- Large-scale manufacturing operations

- Custom glass processing projects

- Critical-edge quality applications

- Industrial production facilities

- Specialized glass workshops

---

Product Advantages

Precision & Quality:

- Delivers uniformly smooth and clear finishes

- Ensures edge perfection critical for high-end applications

- Maintains consistent results across entire glass edge

- Enhances visual/functional product quality

Operational Efficiency:

- Combines grinding and polishing in one compact unit

- Streamlines production processes

- Reduces processing time and resource consumption

- Minimizes defect risks

Versatility:

- Handles diverse glass thicknesses

- Adapts to various processing projects

- Scales from mass production to custom work

Durability & Reliability:

- Robust construction withstands continuous operation

- Corrosion-resistant materials extend lifespan

- Minimal maintenance requirements

- Dependable performance in rigorous conditions

User Convenience:

- Ergonomic design ensures operator comfort

- Real-time monitoring reduces errors

- Maintains productivity during extended shifts

Economic Value:

- Cost-effective long-term investment

- Maintains highest quality standards

- Optimizes production efficiency

---

Technical Summary

The DZM11 Glass Straight-line Single Edging Machine redefines precision as a premier Glass Single Edging Polisher. This comprehensive Glass Processing Machine integrates industrial-grade Glass Grinding machines with advanced Glass edge polishing capabilities, delivering superior results for critical glass finishing applications.

Identification data

Machine: Horizontal edger

Model: DZM11

Voltage and Frequency: 380V, 50Hz

Total power: 22.5kW

Workable thickness: 3~25mm

Weight: 3000kg

Serial no.:

Product date: 2022

Wheel position with respect to the incoming sheet | |||||||||||||||

DZM11 | |||||||||||||||

Ref.no | No11 | No10 | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 | ||||

Rev.(50Hz) | 1400 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | ||||

Rev.(60Hz) | 1680 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | ||||

Name | Polish wheel | Fine grinding wheel | Fine grinding wheel | Resin wheel | Diamond wheel | Fine grinding wheel | Resin wheel | Fine grinding wheel | Resin wheel | Diamond wheel | Diamond wheel | ||||

Specification | SD001 150×70 | 10S60 150×70 | 10S40 150×70 | 150×12 240 mesh | 150×12 180 mesh | 10S40 130×50 | 130×12 240 mesh | 10S40 130×50 | 130×12 240 mesh | 150×12 140 mesh | 150×12 100 mesh | ||||

Usage | Bottom polishing | Bottom fine grinding | Bottom fine grinding | Bottom fine grinding | Semi fine grinding for bottom | Fine grinding for front arris | Semi fine grinding for front arris | Fine grinding for back arris | Semi fine grinding for back arris | Bottom fine grinding | Bottom rough grinding | ||||

Technical data

DZM11 | |

Length [mm] | 7300 |

Width [mm] | 1500 |

Height [mm] | 2500 |

Work top height [mm] | 800±30 |

Total weight [kg] | 3100 |

Workable thickness [mm] | 3~25 |

Minimum glass size [mm]: | 60x60 |

Maximum working weight: | 300 |

per meter of transport [kg / m] | 100 |

Total [kg] | 300 |

Conveyor speed [m / min] | 1~5 |

Tanks: |

|

water [no x l] | 1*165 |

cerium oxide [no x l] (Optional) |

|

Rated voltage [V] | See wiring diagram |

Installed power [kW] | 26 |