Brief introduction

The "DZM" model machines are straight and vertical edging machines, for flat edge working of glass sheets and mirrors. The processing is performed by a series of cup diamond and polishing wheels.

The sheet is loaded by hand on the input conveyor, which moves it inside the edging unit.

Throughout the process the sheet is placed on the conveyor rollers at an angle of about 6 degrees from the vertical.

The conveyor system is motorized: the interaction between the operator and the machine during normal operation is limited to the sheet loading and unloading.

Each machine can be operated by one operator only, assisted if necessary by another person during the sheet loading and unloading. For handling large and heavy sheets (exceeding 30kg), a suitable lifting equipment should be used.

Product Introduction

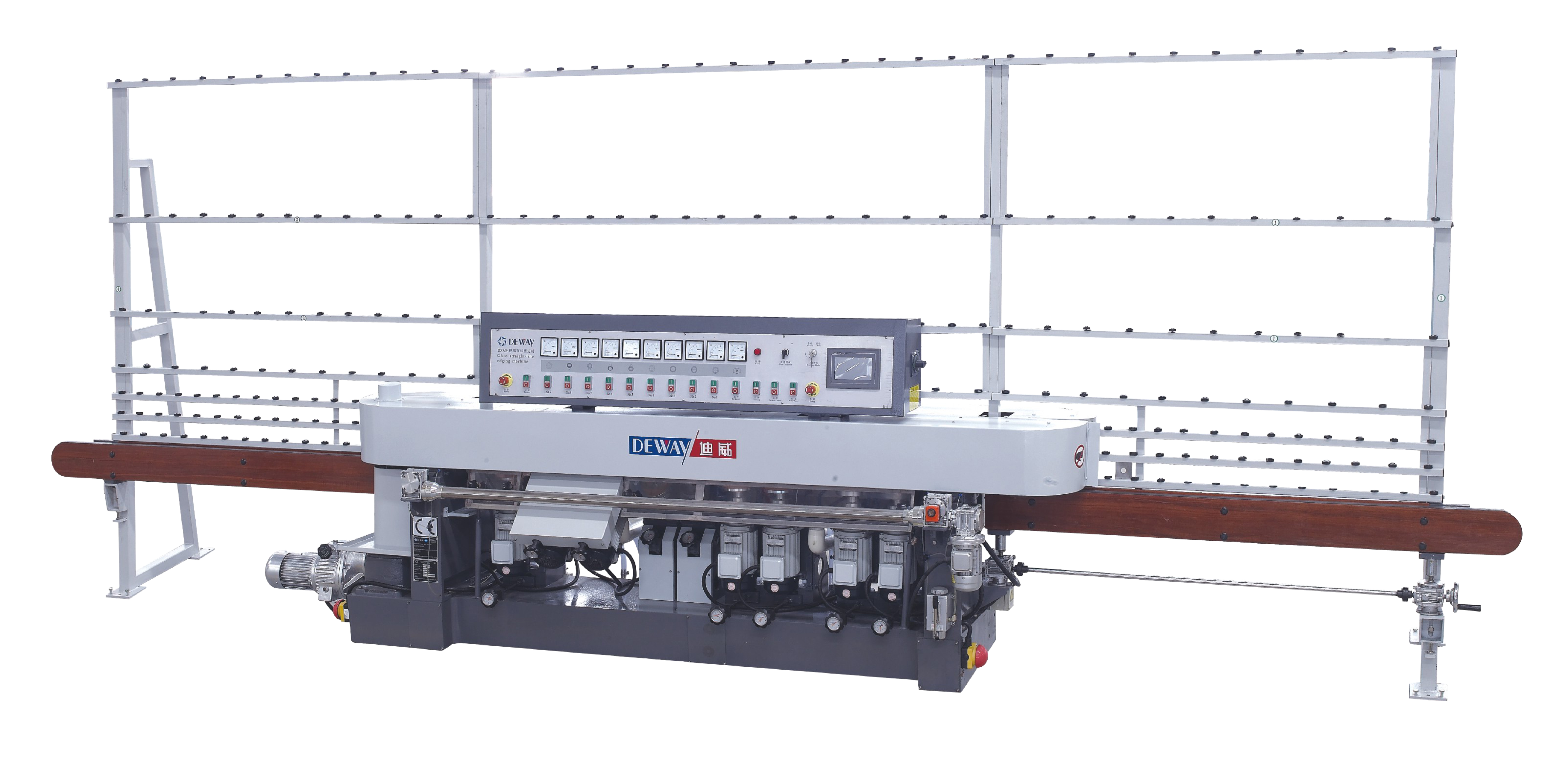

The DZM9 Glass Straight Line Edging Machine is a premium 9-spindle solution engineered for rigorous modern glass processing. This industrial-grade Straight Line Edging machine specializes in creating smooth, accurate flat edges on glass sheets, serving as an essential tool for industries demanding high-quality glass products. Designed for consistency and precision, it processes glass for windows, doors, furniture, and specialized applications.

Product Features

Multi-Spindle Processing System:

- Nine high-precision spindles strategically positioned for sequential operations

- Seamless integration of grinding, polishing, and finishing in a single pass

- Optimized for flat edge straight line edging efficiency

Structural Engineering:

- Heavy-duty construction using robust materials

- Vibration-dampening design ensures operational stability

- Engineered for durability in demanding production environments

Advanced Control System:

- User-friendly interface for precise operational adjustments

- Real-time control of spindle speed, glass thickness, and edge pressure

- Adaptive settings for diverse glass types and dimensions

Integrated Finishing Technology:

- Built-in Straight Line Polisher for perfect edge refinement

- Automated polishing-to-finishing transition

Product Applications

This versatile Glass Straight Line Edging Machine serves:

- Window glass manufacturing

- Door glass production

- Glass furniture fabrication

- Specialized glass product creation

- Industrial-scale production lines

- Small-scale workshop operations

Product Advantages

Precision & Quality:

- Delivers perfectly smooth edges consistently

- Maintains exacting industry standards for edge quality

- Eliminates secondary finishing requirements

Operational Efficiency:

- Single-pass processing reduces production time

- Nine-spindle configuration maximizes throughput

- Minimal operational downtime

Versatility & Adaptability:

- Processes standard and specialized glass products

- Scalable from workshops to industrial lines

- Functions effectively as a high-capacity Glass Single Edger

Economic Value:

- Reduces material waste through precision edging

- Low maintenance requirements enhance ROI

- Durable construction minimizes repair costs

Technical Superiority:

- Stability ensures long-term precision retention

- Intuitive controls reduce operator training time

- Consistent output quality across production runs

Technical Summary

The DZM9 redefines efficiency as a premier Flat Edge Straight Line Edging Machine, combining nine-spindle power with precision engineering. Its integrated Straight Line Polisher guarantees flawless finishes, while its robust construction ensures reliability in continuous operation. As both a high-volume solution and precision Glass Single Edger, it delivers unmatched consistency for competitive glass manufacturing.

Identification data

Machine: Horizontal edger

Model: DZM9

Voltage and Frequency: 380V, 50Hz

Total power: 18.5Kw

Workable thickness: 3~25mm

Weight: 2750kg

Serial no.:

Product date: 2018

| Wheel position with respect to the incoming sheet | |||||||||

| DZM9 | |||||||||

| Ref.no | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 |

| Rev.(50Hz) | 1400 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 |

| Rev.(60Hz) | 1680 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 |

| Name | Felt wheel | Fine grinding wheel | Resin wheel | Fine grinding wheel | Resin wheel | Fine grinding wheel | Resin wheel | Diamond wheel | Diamond wheel |

| Specification | 150 | 10S40 130×50 | 130×50 240 mesh | 10S40 130×50 | 130×50 240 | 10S40 150×70 | 150×12 240 mesh | 150×12 180 mesh | 150×12 100 mesh |

| Usage | Bottom polishing | Fine grinding for front arris | Semi fine grinding for front arris | Fine grinding for back arris | Semi fine grinding for back arris | Bottom polishing | Bottom fine grinding | Semi fine grinding for bottom | Bottom rough grinding |

| DZM8 | |||||||||

| Ref.no | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 | |

| Rev.(50Hz) | 2800 | 2800 | 2800 | 2800 | 1400 | 2800 | 2800 | 2800 | |

| Rev.(60Hz) | 3360 | 3360 | 3360 | 3360 | 1680 | 3360 | 3360 | 3360 | |

| Name | Fine grinding wheel | Resin wheel | Fine grinding wheel | Resin wheel | Polishing wheel | Fine grinding wheel | Resin wheel | Diamond wheel | |

| Specification | 10S40 130×50 | 130×50 240 mesh | 10S40 130×50 | 130×50 240 | X5000 150×50 | 10S40 150×70 | 150×12 240 mesh | 150×12 100 mesh | |

| Usage | Fine grinding for front arris | Semi fine grinding for front arris | Fine grinding for back | Semi fine grinding for back arris | Bottom polishing | Bottom fine grinding | Bottom fine grinding | Bottom rough grinding | |

| DZM4 | |||||||||

| Ref.no | No4 | No3 | No2 | No1 | |||||

| Rev.(50Hz) | 2800 | 2800 | 2800 | 2800 | |||||

| Rev.(60Hz) | 3360 | 3360 | 3360 | 3360 | |||||

| Name | Resin wheel | Resin wheel | Resin wheel | Diamond wheel | |||||

| Specification | 130×50 240 mesh | 130×12 240 mesh | 130×12 240 mesh | 150×12 100 mesh | |||||

| Usage | Back arris Semi-fine grinding | Front arris Semi-fine grinding | Bottom fine grinding | Bottom rough grinding | |||||

Technical data

DZM4 | DZM8 | DZM9 | |

Length [mm] | 4800 | 6600 | 6900 |

Width [mm] | 1500 | ||

Height [mm] | 1800 | 2500 | |

Work top height [mm] | 800±30 | ||

Total weight [kg] | 1600 | 2600 | 2750 |

Workable thickness [mm] | 3~28 | ||

Minimum glass size [mm]: | 120x120 | ||

Maximum working weight: | 200 | 300 | 300 |

per meter of transport [kg / m] | 100 | 100 | 100 |

Total [kg] | 200 | 300 | 300 |

Conveyor speed [m / min] | 1~5 | ||

Tanks: |

|

|

|

water [no x l] | 1*165 | 1*165 | 1*165 |

cerium oxide [no x l] (Optional) |

|

| 1*75 |

Rated voltage [V] | See wiring diagram | ||

Installed power [kW] | 9.3 | 16.7 | 18.5 |