Product Introduction

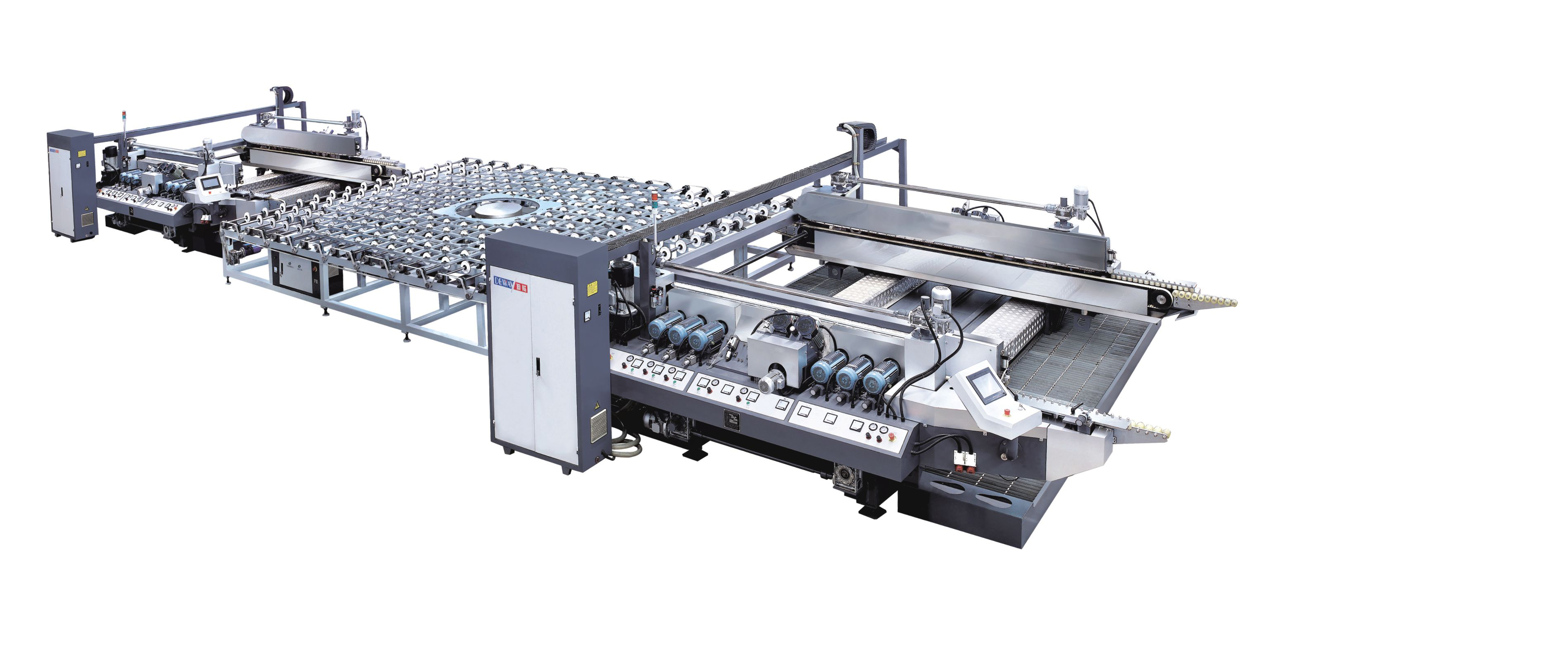

The DZT4225 Automatic Glass Transfer Table revolutionizes material handling in glass manufacturing. Engineered as a multifunctional Glass Transfer Table, it seamlessly integrates with processing lines to automate panel positioning, loading, and transfer - eliminating manual handling for large-format glass up to 4200x2500mm.

Product Features

- Dual-Function Design: Operates as both Glass Double Edging Transfer Table and universal Glass Loading Table

- Precision Alignment: Laser-guided positioning (±0.1mm accuracy)

- Adaptive Programming: Handles 3-25mm thickness & 500x500mm to 4200x2500mm sizes

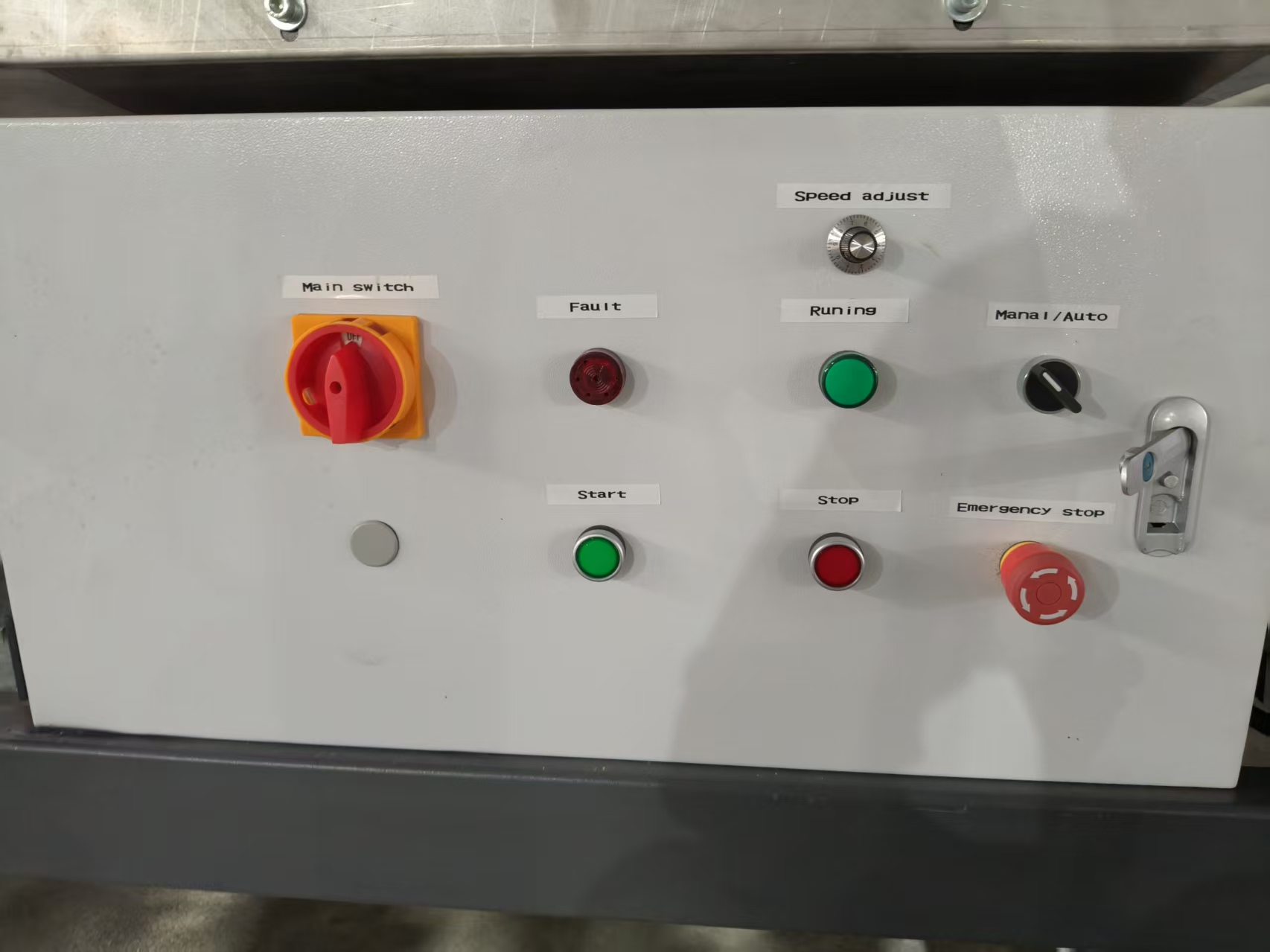

- Automatic Glass Transfer Machine System: PLC-controlled conveyor synchronization

- Heavy-Duty Construction: 5-ton capacity with reinforced steel frame

- Safety Integration: Emergency stops + protective barriers + obstacle detection

- Intelligent HMI: 10" touchscreen with 100+ recipe storage

Product Applications

- Transfer hub between cutting/edging/tempering stations

- Precision positioning for double edging lines

- Loading interface for CNC processing centers

- Automotive glass production lines

- Architectural glass facility material handling

- High-volume mirror manufacturing

Product Advantages

- Labor Elimination: Reduces manual handling by 85% as Automatic Glass Transfer Machine

- Line Synchronization: Cuts transfer time between processes by 70%

- Precision Alignment: Ensures ±0.2° angular accuracy as Glass Double Edging Transfer Table

- Multifunctional Efficiency: Combines transfer/loading in single Glass Loading Table system

- 99% Operational Uptime: IP54-rated components withstand harsh environments

- 30% Space Optimization: Replaces multiple material handling systems

- Accident Reduction: Safety system complies with ISO 13849 PL e

- ROI Acceleration: 12-month payback period via 45% productivity increase

Certifications

- CE, UL, and GB 5226.1 certified

- ISO 13849-1 (PLe) safety rating

- ANSI B11.19 performance standards

Operational Economics

- Energy Consumption: 8.5kW average

- Maintenance Cost: <$0.01/sqm over 10-year lifecycle

- Throughput Gain: 150+ panels/hour continuous transfer

This Glass Transfer Table sets new benchmarks in automated glass logistics, enabling seamless integration with Industry 4.0 production systems. As the cornerstone Automatic Glass Transfer Table for modern glass facilities, it eliminates handling damage while accelerating line changeovers - achieving 30% faster cycle times versus conventional systems.

Technical data

- Table hieght:900±50mm (can be adjusted)

- Max glass size:4200mmmm×2500mm×19mm

- Min glass size:300mm×300mm;

- Glass thickness:3~19mm;

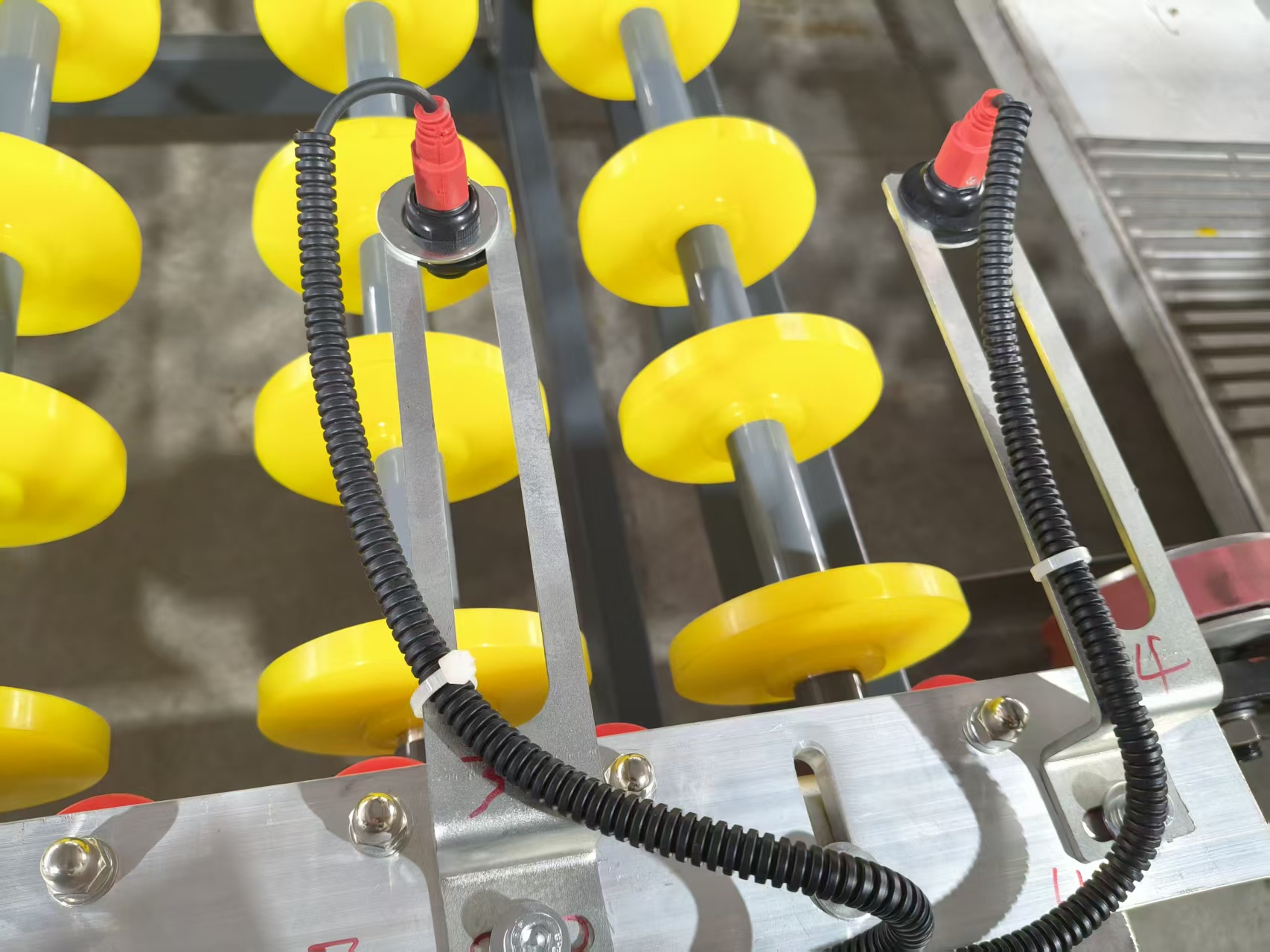

- Convey belt speed:0~30m/min(frequency conversion);

- belt type No.:29.5AT10-5200;

- Roller conveying speed:0~30m/min(frequency conversion);

- Roller diameter Yellow;

- Speed:8~10 second秒/pc片;

- Power:5kw;

- Voltage : 380v50hz

- Weight around: 1.8T