Product Introduction

The DZM12 Glass Edging Machine (12 Spindles) is an advanced piece of equipment designed specifically for precision work in the glass processing industry. As a Glass Straight-line Edging Machine, the DZM12 offers unparalleled accuracy and efficiency, making it an ideal choice for businesses focused on high-quality glass products. Equipped with 12 spindles, this machine is capable of performing complex edging tasks on flat glass surfaces with remarkable consistency. The DZM12 excels as a Glass Flat Edging Machine, providing clean and smooth edges essential for both aesthetic appeal and safety. Furthermore, in addition to edging, the DZM12 functions effectively as a Glass Polishing Machine, enhancing the clarity and smoothness of the glass surface after the initial edging process. As a Glass Flat Edger, it is designed to handle a wide range of glass thicknesses and sizes. The DZM12 also doubles as a Glass Flat Polisher, offering a comprehensive solution for glass finishing. This versatile and reliable tool is engineered to meet and exceed expectations for efficiency, precision, and final finish quality in glass processing.

---

Product Features

1. 12-Spindle Configuration: Features 12 high-precision spindles strategically arranged to ensure uniform processing of glass edges, minimizing imperfections. This configuration enables complex edging tasks on flat glass.

2. Precision Straight-Line Edging: Functions as a high-accuracy Glass Straight-line Edging Machine, delivering unparalleled consistency for flat glass surfaces.

3. Superior Flat Edge Finishing: Operates as an effective Glass Flat Edging Machine and Glass Flat Edger, producing clean, smooth, and safe edges critical for final product quality.

4. Integrated Polishing Capability: Seamlessly transitions to function as a Glass Polishing Machine and Glass Flat Polisher after edging, enhancing surface clarity and smoothness to achieve a high-quality finish.

5. Wide Application Range: Capable of handling a broad spectrum of glass thicknesses and sizes – from thin decorative panels to thick structural glass – delivering consistent results as both a Glass Flat Edger and Glass Flat Polisher.

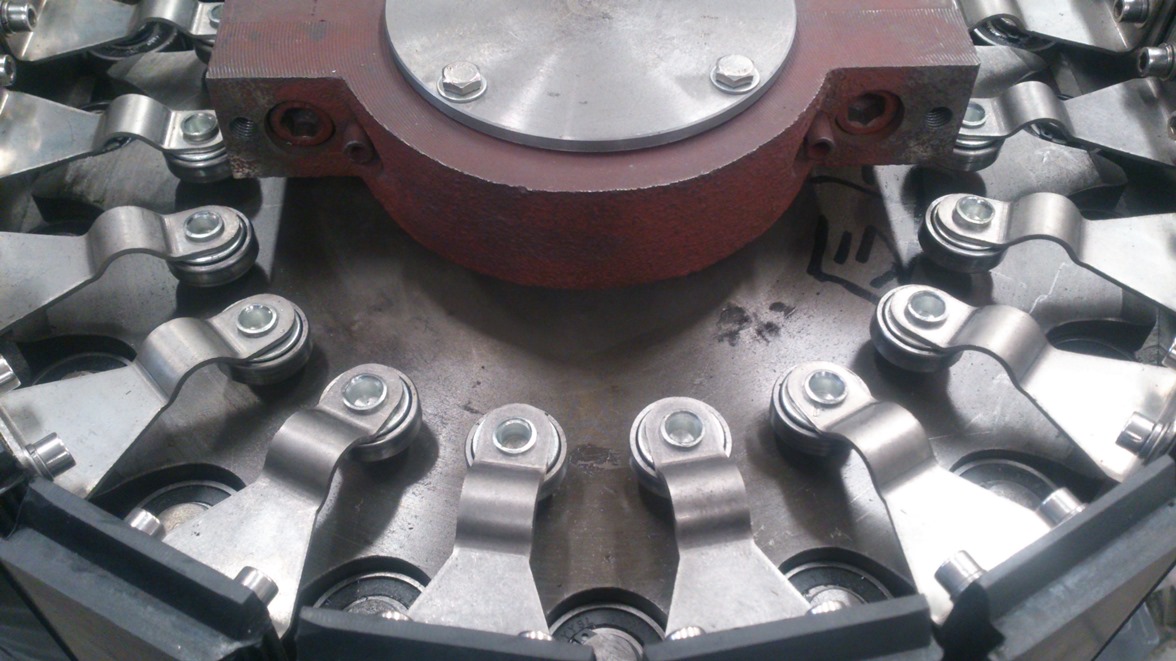

6. Robust Construction: Built with high-performance components to withstand continuous operation in demanding large-scale production environments, ensuring long-term reliability.

7. User-Friendly Operation: Equipped with intuitive controls and automated features, allowing operators to achieve precise results with minimal effort.

---

Product Applications

The DZM12 Glass Straight-line Edging Machine and Glass Polishing Machine is essential for producing high-quality glass products where edge precision, finish, and safety are paramount. Its capabilities as a Glass Flat Edging Machine and Glass Flat Edger are crucial for applications where glass edges are exposed and require a flawless appearance and tactile smoothness. Key application areas include:

1. Architectural Glass: Processing edges and polishing glass for windows, doors, facades, partitions, railings, and other building elements where aesthetics and safety are critical.

2. Glass Furniture: Edging and polishing table tops, shelves, cabinets, and other furniture components requiring precise, smooth, and safe edges.

3. Mirrors: Providing clean, precise edges and high-clarity polished surfaces for decorative, bathroom, and furniture mirrors.

4. Decorative Glass Panels: Handling thin glass for artistic or functional decorative applications, ensuring perfect edges and finishes.

5. Structural Glass Components: Processing thicker glass used in load-bearing or safety-critical applications, where consistent edge quality and strength are essential.

---

Product Advantages

1. Unparalleled Precision & Consistency: The strategic arrangement of 12 spindles ensures uniform processing, minimizing imperfections and delivering exceptional accuracy as a Glass Straight-line Edging Machine and Glass Flat Edging Machine.

2. High Efficiency & Productivity: Capable of performing complex edging and seamless polishing in one setup, significantly speeding up the production process for high-quality glass products.

3. Exceptional Edge & Surface Quality: Delivers clean, smooth, and safe edges essential for aesthetics and safety as a Glass Flat Edger, and achieves high-clarity, smooth polished surfaces as a Glass Polishing Machine and Glass Flat Polisher, meeting the demands of discerning clients.

4. Versatility & Flexibility: Functions effectively across multiple roles – Glass Straight-line Edging Machine, Glass Flat Edging Machine, Glass Polishing Machine, Glass Flat Edger, and Glass Flat Polisher – while handling a wide range of glass thicknesses and sizes, from thin decorative panels to thick structural glass.

5. Production Streamlining: Combines edging and polishing capabilities, reducing the need for multiple separate machines and simplifying the workflow, making it a valuable asset in any glass processing operation.

6. Enhanced Operational Efficiency: Intuitive controls and automation features minimize operator effort and skill requirements while maximizing output consistency.

7. Reliability for Demanding Environments: Robust construction ensures the machine can withstand the rigors of continuous, large-scale industrial production, providing dependable long-term performance.

8. Comprehensive Finishing Solution: Offers a complete edge-to-polish solution, ensuring the final glass product meets the highest standards of quality for diverse applications.

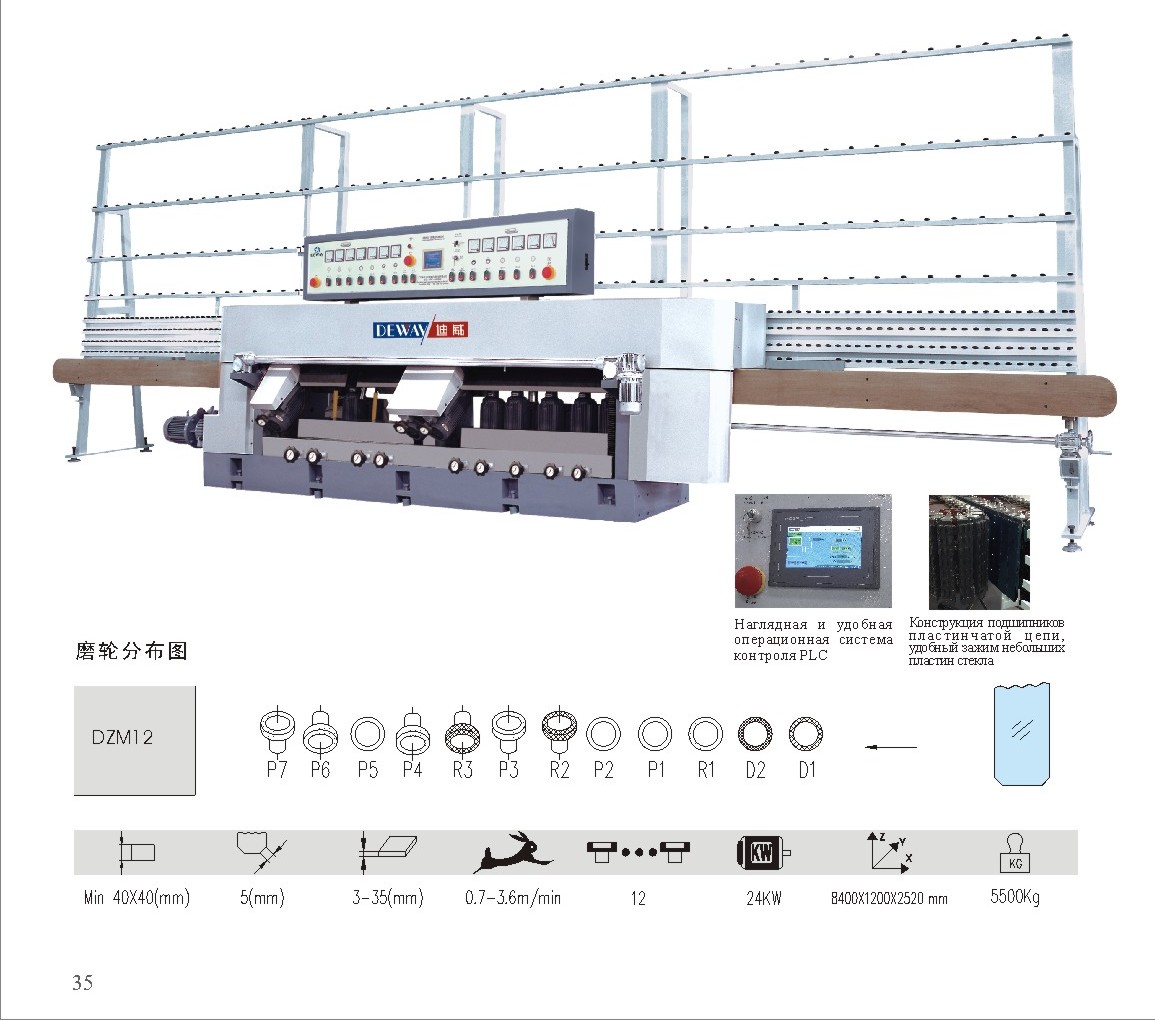

Identification data

Machine: Horizontal edger

Model: DZM12

Voltage and Frequency: 380V, 50Hz

Total power: 24.7kW

Workable thickness: 3~25mm

Weight: 3000kg

Serial no.:

Product date: 2022

Wheel position with respect to the incoming sheet | ||||||||||||||||

DZM12 | ||||||||||||||||

Ref.no | No12 | No11 | No10 | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 | ||||

Rev.(50Hz) | 1400 | 2800 | 2800 | 1400 | 2800 | 2800 | 1400 | 2800 | 2800 | 2800 | 2800 | 2800 | ||||

Rev.(60Hz) | 1680 | 3360 | 3360 | 1680 | 3360 | 3360 | 1680 | 3360 | 3360 | 3360 | 3360 | 3360 | ||||

Name | Polishing wheel | Polishing wheel | Resin wheel | Polishing wheel | Polishing wheel | Resin wheel | Polishing wheel | Polishing wheel | Polishing wheel | Resin wheel | Diamond wheel | Diamond wheel | ||||

Specification | CE3 130×50 | 10S40 130×50 | 130×22 240 mesh | CE3 130×50 | 10S40 130×50 | 130×22 240 mesh | X098 | 10S60 150×70 | 10S40 150×70 | 150×22 240 mesh | 150×22 180 mesh | 150×22 100 mesh | ||||

Usage | Polishing for front arris | Polishing for front arris | Fine grinding for front arris | Polishing for back arris | Polishing for back arris | Fine grinding for back arris | Bottom polishing | Bottom polishing | Bottom polishing | Bottom fine grinding | Semi fine grinding for bottom | Bottom rough grinding | ||||

Technical data

DZM12 | |

Length [mm] | 7500 |

Width [mm] | 1500 |

Height [mm] | 2500 |

Work top height [mm] | 800±30 |

Total weight [kg] | 3100 |

Workable thickness [mm] | 3~25 |

Minimum glass size [mm]: | 120x120 |

Maximum working weight: | 300 |

per meter of transport [kg / m] | 100 |

Total [kg] | 300 |

Conveyor speed [m / min] | 1~5 |

Tanks: |

|

water [no x l] | 1*165 |

cerium oxide [no x l] (Optional) |

|

Rated voltage [V] | See wiring diagram |

Installed power [kW] | 26 |