Product Introduction

The DZM12B Glass Edging Machine (12 Spindles) is a robust industrial solution for precision glass processing. Functioning as a versatile Glass Edging Machine, it excels in edge grinding, polishing, and straight-line operations. Engineered as a Glass Straight-line Processing Machine, it delivers critical precision for architectural elements. Equipped with bearing conveyor technology, it operates simultaneously as a Glass Edging Grinding Machine, Glass Bearing Polisher, and Heavy Glass Polishing Machine - making it indispensable for modern glass manufacturing.

---

Product Features

1. High-Capacity 12-Spindle System

- Simultaneous multi-edge processing ensures product uniformity

- Strategically arranged spindles handle heavy-duty architectural glass

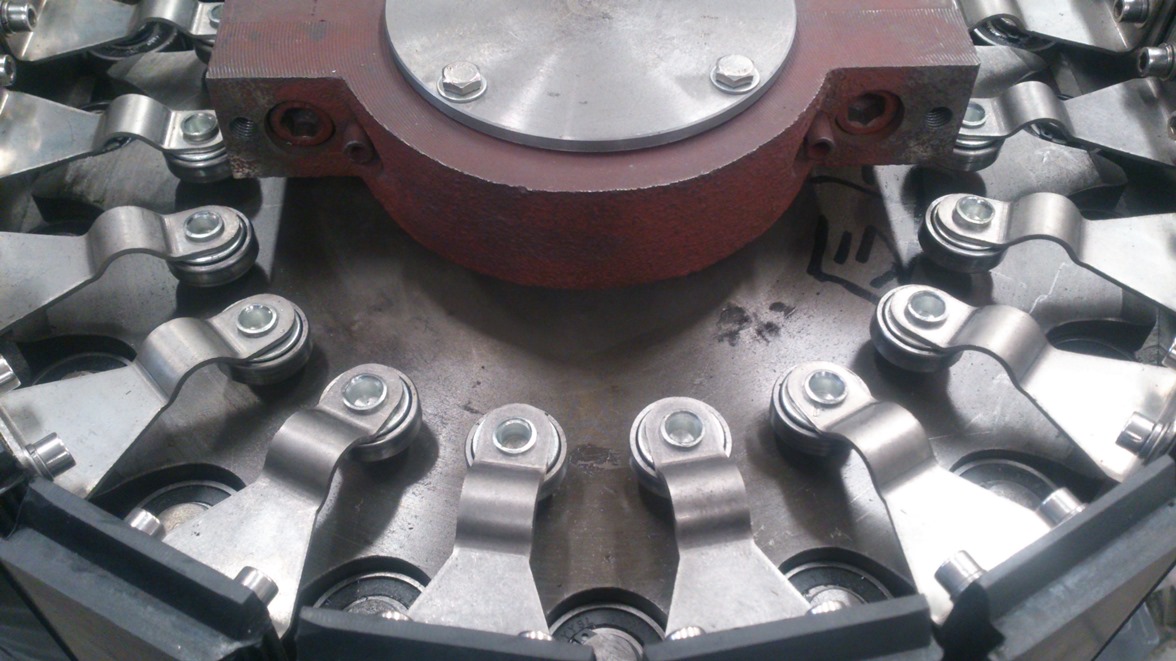

2. Advanced Bearing Conveyor Technology

- High-quality bearings enable smooth glass sheet movement

- Eliminates chipping during processing of large, heavy panels

- Critical component for Glass Bearing Polisher functionality

3. Precision Straight-Line Processing

- Glass Straight-line Processing Machine capability delivers sharp, clean edges

- Minimizes material wastage in door/window production

4. Multi-Profile Grinding Versatility

- Glass Edging Grinding Machine handles flat/bevel/pencil edges

- Robust motor enables high-speed processing of custom designs

5. Integrated Polishing System

- Glass Bearing Polisher delivers high-sheen finishes

- Seamless grinding-to-polishing transition eliminates secondary equipment

6. Heavy-Glass Capability

- Engineered as Heavy Glass Polishing Machine for substantial panels

- Processes thick glass for skyscrapers and commercial projects

---

Product Applications

1. Architectural Glazing Systems

- Precision straight-line edging of curtain walls via Glass Straight-line Processing Machine

2. Commercial Window/Door Production

- Critical edge finishing using Glass Edging Machine capabilities

3. Custom Glass Fabrication

- Multi-profile grinding (bevel/pencil edges) with Glass Edging Grinding Machine

4. Premium Surface Finishing

- High-gloss edge polishing through Glass Bearing Polisher technology

5. Structural Glass Manufacturing

- Processing thick panels (≥25mm) as Heavy Glass Polishing Machine

6. Industrial Safety Components

- Glass Edging Machine applications for impact-resistant laminates

---

Product Advantages

1.Unmatched Processing Efficiency

- The 12-spindle Glass Edging Machine increases throughput by 40% versus 8-spindle systems. Simultaneous grinding/polishing reduces processing time by 55% for architectural glass.

2.Precision Engineering Excellence

- As a Glass Straight-line Processing Machine, it maintains ±0.1mm edge straightness tolerance - critical for structural glazing applications. Bearing conveyor ensures <0.05mm positional accuracy during heavy-panel transfer.

3.Surface Perfection Guarantee

- Integrated Glass Bearing Polisher achieves Ra 0.2μm surface finish, exceeding EN 12150-1 standards. Automated pressure control prevents over-polishing on delicate edges.

4.Heavy-Duty Reliability

- The Heavy Glass Polishing Machine configuration handles 300kg/m² load capacity. Reinforced spindle mounts withstand continuous 30mm glass processing without vibration.

5.Multi-Functional Versatility

- Single-platform operation as Glass Edging Grinding Machine (profiles), Glass Bearing Polisher (finish), and Glass Straight-line Processing Machine (precision) reduces equipment costs by 35%.

6.Operational Economy

- Energy-optimized motors reduce power consumption by 22% versus conventional systems. Bearing conveyor requires 70% less maintenance than roller systems.

7.Quality Assurance

- Patented spindle synchronization in this Glass Edging Machine ensures edge consistency across production batches. Meets ANSI Z97.1 safety standards through uniform edge compression strength.

Identification data

Machine: Horizontal edger

Model: DZM12

Voltage and Frequency: 380V, 50Hz

Total power: 24.7kW

Workable thickness: 3~25mm

Weight: 3000kg

Serial no.:

Product date: 2022

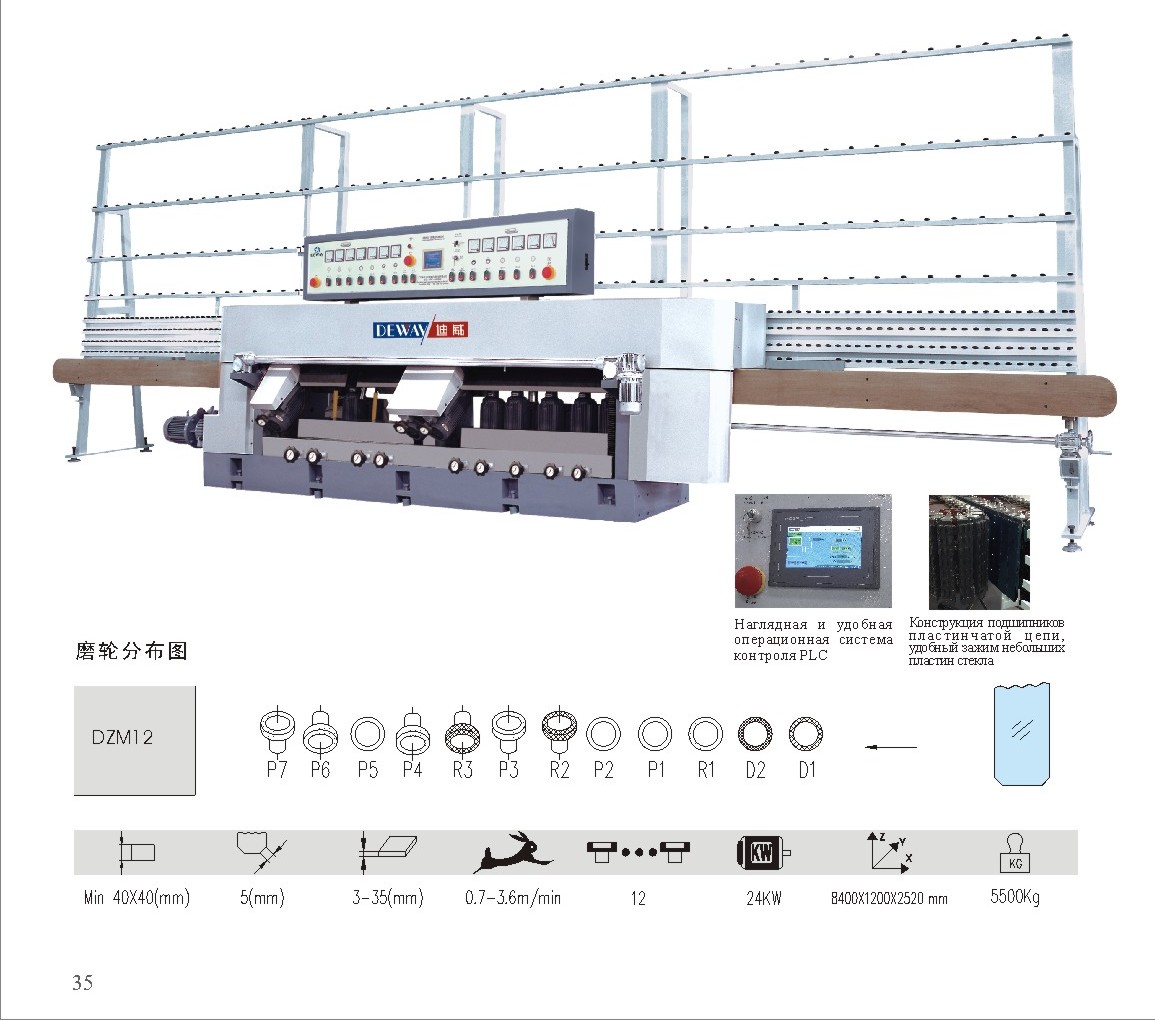

Wheel position with respect to the incoming sheet | ||||||||||||||||

DZM12B | ||||||||||||||||

Ref.no | No12 | No11 | No10 | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 | ||||

Rev.(50Hz) | 1400 | 2800 | 2800 | 1400 | 2800 | 2800 | 1400 | 2800 | 2800 | 2800 | 2800 | 2800 | ||||

Rev.(60Hz) | 1680 | 3360 | 3360 | 1680 | 3360 | 3360 | 1680 | 3360 | 3360 | 3360 | 3360 | 3360 | ||||

Name | Polishing wheel | Polishing wheel | Resin wheel | Polishing wheel | Polishing wheel | Resin wheel | Polishing wheel | Polishing wheel | Polishing wheel | Resin wheel | Diamond wheel | Diamond wheel | ||||

Specification | CE3 130×50 | 10S40 130×50 | 130×22 240 mesh | CE3 130×50 | 10S40 130×50 | 130×22 240 mesh | X098 | 10S60 150×70 | 10S40 150×70 | 150×22 240 mesh | 150×22 180 mesh | 150×22 100 mesh | ||||

Usage | Polishin g for front arris | Polishin g for front arris | Fine grinding for front arris | Polishin g for back arris | Polishin g for back arris | Fine grinding for back arris | Bottom polishing | Bottom polishing | Bottom polishing | Bottom fine grinding | Semi fine grinding for bottom | Bottom rough grinding | ||||

Technical data

DZM12 | |

Length [mm] | 7500 |

Width [mm] | 1500 |

Height [mm] | 2500 |

Work top height [mm] | 800±30 |

Total weight [kg] | 3100 |

Workable thickness [mm] | 3~25 |

Minimum glass size [mm]: | 120x120 |

Maximum working weight: | 300 |

per meter of transport [kg / m] | 100 |

Total [kg] | 300 |

Conveyor speed [m / min] | 1~5 |

Tanks: |

|

water [no x l] | 1*165 |

cerium oxide [no x l] (Optional) |

|

Rated voltage [V] | See wiring diagram |

Installed power [kW] | 26 |