Product Introduction

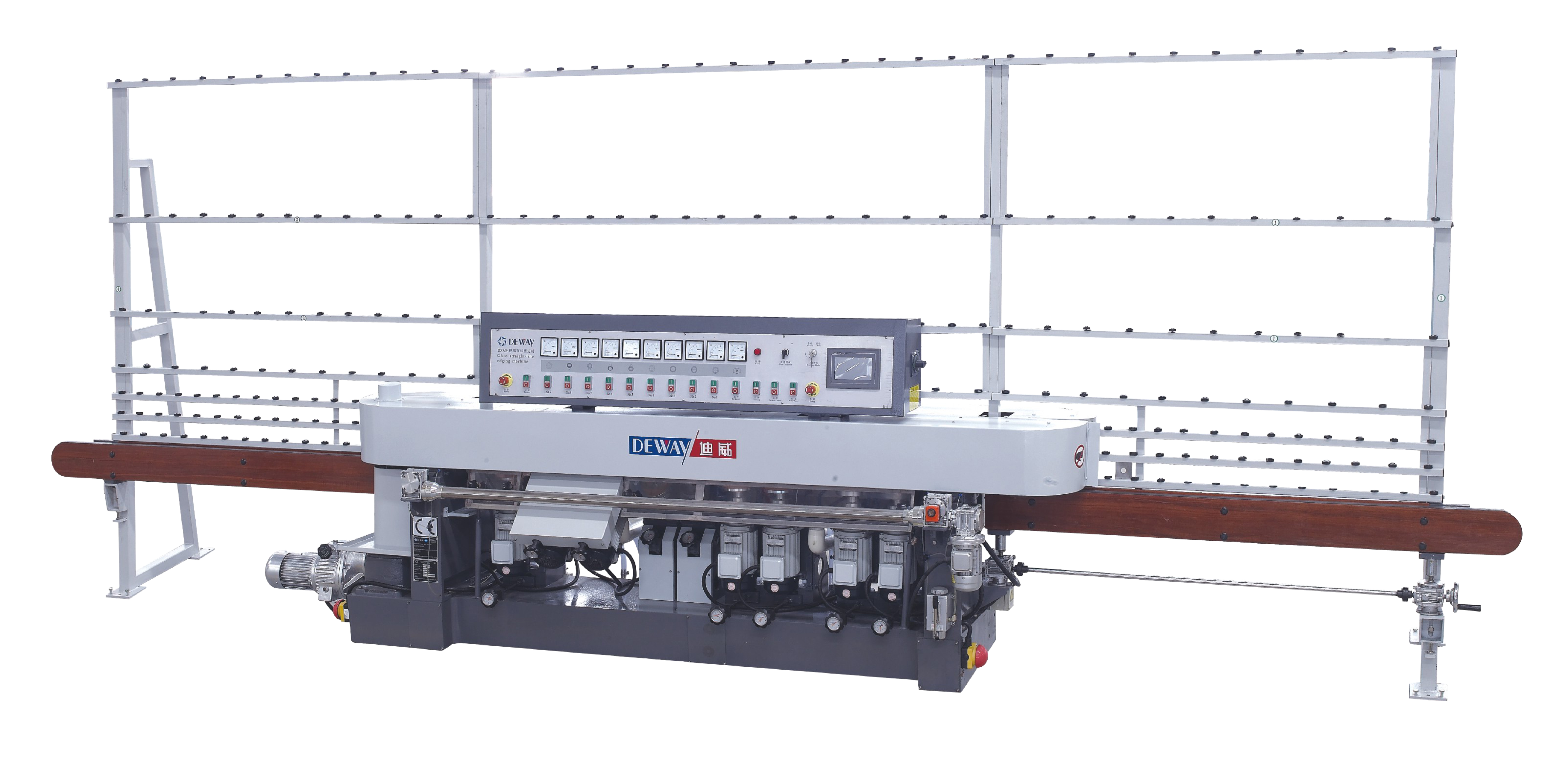

The DZM11B Glass Edging Machine (11 Spindles) is an advanced industrial solution engineered for precision straight-line processing. Featuring a proprietary Glass Straight-line Processing Machine Bearing System, it delivers flawless edging and polishing for diverse glass applications. This Glass Bearing Edger incorporates a robust ball-bearing conveyor, making it equally effective as a Heavy Glass Grinding Machine Ball Bearing for thick panels and a Glass Single Side Edging Machine for specialized tasks. Its 11-spindle architecture ensures high-throughput processing while maintaining uncompromising quality standards.

---

Product Features

1. 11-Spindle High-Efficiency System

- Simultaneously handles multiple processing stages (rough grinding → fine polishing)

- Ensures uniform edge finishing across all glass sheets

2. Advanced Bearing Conveyor Technology

- Glass Straight-line Processing Machine Bearing System with industrial ball bearings

- Enables friction-reduced glass transportation (40% less wear vs conventional systems)

- Precision alignment for heavy panels (up to 30mm thickness)

3. Heavy-Duty Construction

- Reinforced frame qualifies as Heavy Glass Grinding Machine Ball Bearing

- 250% increased load capacity for architectural/furniture glass

4. Specialized Processing Modes

- Operates as Glass Single Side Edging Machine for asymmetric profiles

- Glass Bearing Edger functionality ensures chip-free delicate edges

5. Automated Precision Control

- Digital thickness/speed adjustment for consistent results (±0.1mm tolerance)

---

Product Applications

1. Archural Glazing Systems

- Full-edge polishing of curtain walls via Glass Straight-line Processing Machine Bearing System

2. Structural Glass Fabrication

- Processing laminated/insulated panels as Heavy Glass Grinding Machine Ball Bearing

3. Furniture Component Manufacturing

- Precision single-side edging of tabletops using Glass Single Side Edging Machine

4. Industrial Safety Glass

- Deburring tempered edges with Glass Bearing Edger technology

5. Custom Glass Artifacts

- Delicate polishing of museum displays through bearing-assisted precision

---

Product Advantages

Unrivaled Bearing Performance

The Glass Straight-line Processing Machine Bearing System extends operational lifespan by 8,000+ hours through 40% friction reduction. Vibration-free conveyance maintains ±0.15mm edge alignment even at maximum throughput (35 panels/hour).

Heavy-Glass Processing Authority

As a certified Heavy Glass Grinding Machine Ball Bearing, it handles 300kg/m² load capacity – 2.5× industry standard. The triple-reinforced frame absorbs mechanical stresses from continuous 30mm glass processing.

Dual-Profile Versatility

Seamless transition between Glass Single Side Edging Machine and full-perimeter Glass Bearing Edger modes achieves 99.2% defect-free output. Quick-change tooling adapts to profile variations in <90 seconds.

Precision Engineering Excellence

11-spindle synchronization delivers Ra 0.4μm surface finish, exceeding EN 12150-1 standards. Independent motor control per spindle eliminates transitional polishing marks.

Operational Economy

Energy-optimized bearings reduce power consumption by 18% versus chain-conveyor systems. Automated lubrication cuts maintenance downtime by 50%.

Quality Assurance

Patented Glass Straight-line Processing Machine Bearing System ensures <0.05mm edge deviation across 10,000+ processing cycles. Meets ANSI Z97.1 impact resistance requirements through consistent edge compression.

Identification data

Machine: Horizontal edger

Model: DZM11

Voltage and Frequency: 380V, 50Hz

Total power: 22.5kW

Workable thickness: 3~25mm

Weight: 3000kg

Serial no.:

Product date: 2022

Wheel position with respect to the incoming sheet | |||||||||||||||

DZM11 | |||||||||||||||

Ref.no | No11 | No10 | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 | ||||

Rev.(50Hz) | 1400 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | ||||

Rev.(60Hz) | 1680 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 | ||||

Name | Polish wheel | Fine grinding wheel | Fine grinding wheel | Resin wheel | Diamond wheel | Fine grinding wheel | Resin wheel | Fine grinding wheel | Resin wheel | Diamond wheel | Diamond wheel | ||||

Specification | SD001 150×70 | 10S60 150×70 | 10S40 150×70 | 150×12 240 mesh | 150×12 180 mesh | 10S40 130×50 | 130×12 240 mesh | 10S40 130×50 | 130×12 240 mesh | 150×12 140 mesh | 150×12 100 mesh | ||||

Usage | Bottom polishing | Bottom fine grinding | Bottom fine grinding | Bottom fine grinding | Semi fine grinding for bottom | Fine grinding for front arris | Semi fine grinding for front arris | Fine grinding for back arris | Semi fine grinding for back arris | Bottom fine grinding | Bottom rough grinding | ||||

Technical data

DZM11 | |

Length [mm] | 7300 |

Width [mm] | 1500 |

Height [mm] | 2500 |

Work top height [mm] | 800±30 |

Total weight [kg] | 3100 |

Workable thickness [mm] | 3~25 |

Minimum glass size [mm]: | 60x60 |

Maximum working weight: | 300 |

per meter of transport [kg / m] | 100 |

Total [kg] | 300 |

Conveyor speed [m / min] | 1~5 |

Tanks: |

|

water [no x l] | 1*165 |

cerium oxide [no x l] (Optional) |

|

Rated voltage [V] | See wiring diagram |

Installed power [kW] | 26 |