Product Introduction

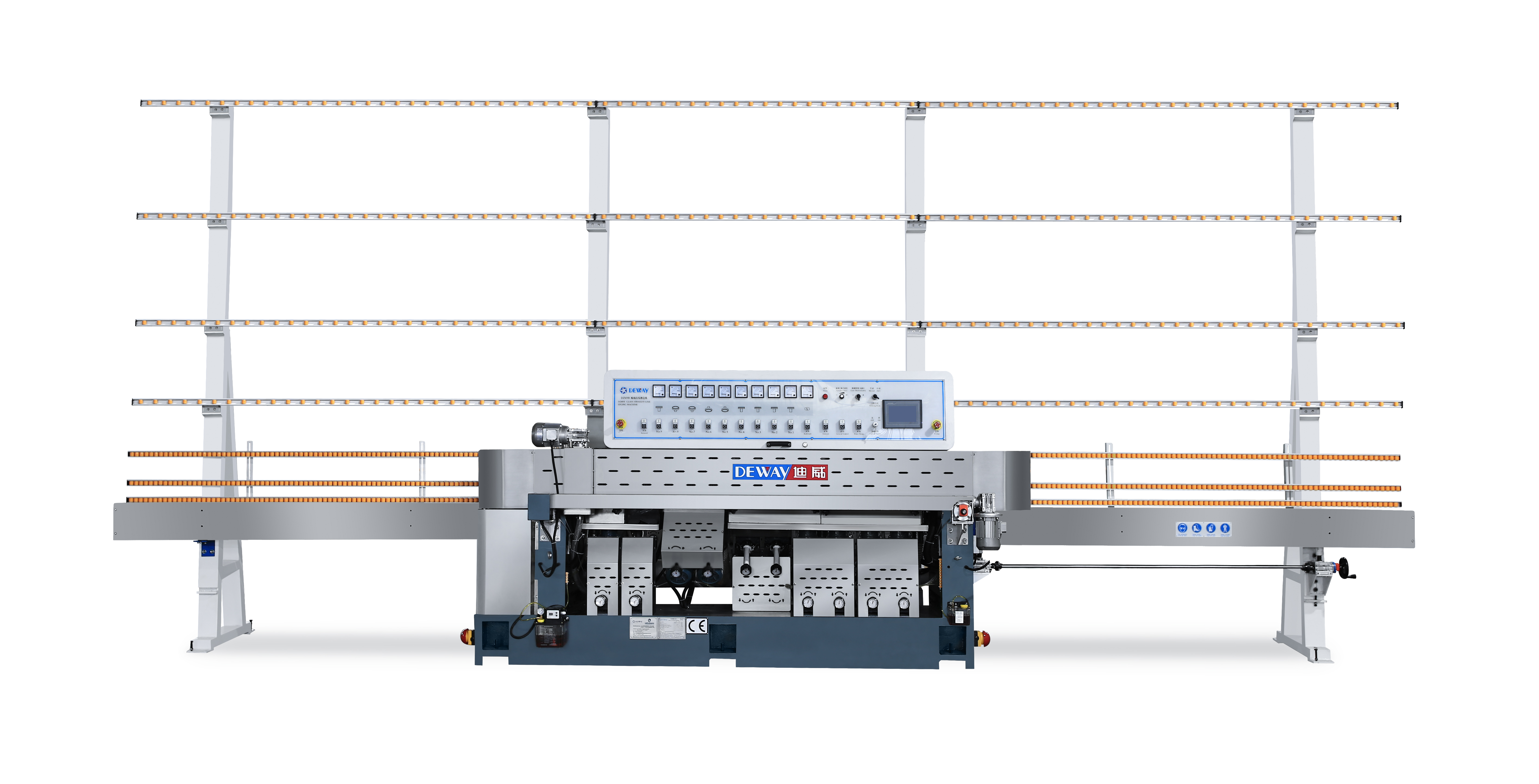

The DZM10B Glass Edging Machine (10 Spindles) is an industrial-grade solution engineered for precision straight-line glass processing. Its defining innovation is the Glass Straight-line Edging Machine Bearing System–a proprietary technology that revolutionizes glass handling. Functioning as both a Glass Straight-line Bearing Machine and Glass Bearing Edging Machine, it delivers exceptional stability for heavy panels while enabling delicate operations through its Glass Single Edging Machine Ball Bearing mechanism. Designed as a robust Heavy Glass Grinding Machine, it meets the rigorous demands of architectural and industrial glass fabrication.

---

Product Features

1. High-Capacity Spindle Configuration

- 10 precision spindles enable simultaneous processing of glass sheets

- Integrated workflow from rough grinding to fine polishing in a single pass

2. Advanced Bearing Conveyor System

- Glass Straight-line Edging Machine Bearing System with industrial-grade ball bearings

- Near-frictionless glass transportation (60% wear reduction)

- Glass Single Edging Machine Ball Bearing mechanism prevents edge chipping

3. Heavy-Duty Structural Design

- Reinforced frame and high-torque motors for Heavy Glass Grinding Machine applications

- 300% greater load capacity than standard edgers

4. Multi-Functional Precision Engineering

- Seamless transition between Glass Straight-line Bearing Machine and Glass Bearing Edging Machine modes

- Processes glass thicknesses from 3mm to 30mm without recalibration

5. Operator-Centric Controls

- Intuitive digital interface for real-time adjustment of speed/pressure parameters

---

Product Applications

1. Structural Glazing Systems

- Precision straight-line edging of load-bearing curtain walls using the Glass Straight-line Edging Machine Bearing System

2. Industrial Heavy Glass

- Processing armored/laminated glass panels (>25mm thickness) as a certified Heavy Glass Grinding Machine

3. Premium Architectural Elements

- Flawless edge finishing on glass stair treads and partitions via Glass Bearing Edging Machine

4. Delicate Specialty Glass

- Museum display cases and anti-reflective glass processing enabled by Glass Single Edging Machine Ball Bearing technology

5. High-Volume Production

- Glass Straight-line Bearing Machine configuration for mass production of shower enclosures and furniture components

---

Product Advantages

Revolutionary Bearing Performance

The Glass Straight-line Edging Machine Bearing System extends equipment lifespan by 5+ years through 60% friction reduction. Its ball-bearing conveyor ensures vibration-free glass handling even at maximum throughput (40 panels/hour).

Unmatched Heavy-Glass Capability

As a dedicated Heavy Glass Grinding Machine, it delivers 300% greater load capacity versus conventional edgers. The reinforced chassis absorbs operational stresses from 30mm-thick architectural panels.

Dual-Mode Precision Engineering

Operating as both Glass Straight-line Bearing Machine and Glass Bearing Edging Machine, it achieves ±0.05mm edge consistency across all profiles. The integrated workflow eliminates secondary processing.

Delicate Operation Assurance

The Glass Single Edging Machine Ball Bearing system maintains <0.1% breakage rate during fragile glass processing. Precision-bearing alignment prevents micro-chipping on tempered edges.

Operational Efficiency

15% energy savings are achieved through optimized bearing kinematics. Quick-change tooling allows transitions between bearing-conveyor modes in under 3 minutes.

Industry Compliance

Meets ANSI Z97.1 safety standards for architectural glass through the Glass Bearing Edging Machine's consistent edge compression strength.

Identification data

Machine: Horizontal edger

Model: DZM10

Voltage and Frequency: 380V, 50Hz

Total power: 25.0Kw

Workable thickness: 3~25mm

Weight: 5500kg

Serial no.:

Product date: 2024

Wheel position with respect to the incoming sheet | ||||||||||||||

DZM10 | ||||||||||||||

Ref.no | No10 | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 | ||||

Rev.(50Hz) | 1400 | 2800 | 2800 | 2800 | 1400 | 2800 | 2800 | 2800 | 2800 | 2800 | ||||

Rev.(60Hz) | 1680 | 3360 | 3360 | 3360 | 1680 | 3360 | 3360 | 3360 | 3360 | 3360 | ||||

Name | Fine grinding wheel | Resin wheel | Fine grinding wheel | Resin wheel | Felt wheel | Fine grinding wheel | Fine grinding wheel | Resin wheel | Diamond wheel | Diamond wheel | ||||

Specification | 10S40 130×50 | 130×50 240 mesh | 10S40 130×50 | 130×50 240 mesh | CE3 150×70 | 10S60 150×70 | 10S40 130×70 | 150×12 240 mesh | 150×12 240 mesh | 150×12 100 mesh | ||||

Usage | Fine grinding for back arris | Semi fine grinding for back arris | Fine grinding for front arris | Semi fine grinding for front arris | Bottom polishing | Bottom fine grinding | Bottom fine grinding | Semi fine grinding for bottom | Bottom fine grinding | Bottom rough grinding | ||||

Technical data

DZM10 | |

Length [mm] | 7200 |

Width [mm] | 1200 |

Height [mm] | 2500 |

Workable thickness [mm] | 3~30 |

Minimum glass size [mm]: | 30x30 |

Conveyor speed [m / min] | 0.5~5 |

Tanks: | 1 |

| Rated voltage [V] | 380 |

Installed power [kW] | 25 |