Product Introduction

The DSYM0815 Glass Double Pencil Edging Machine is an industrial-grade solution engineered for precision-rounded edge processing. As the cornerstone of modern Glass Double Pencil Edging Processing Lines, it delivers flawless double pencil edges that enhance both aesthetic appeal and structural safety for furniture, automotive, and architectural glass applications. This versatile system integrates Glass Double C-Edge Machine capabilities within a single platform, enabling complex profile creation without retooling.

Product Features

- Dual-Edge Synchronization: Simultaneous processing of both glass surfaces

- Double Pencil Line Precision: ≤0.08mm contour consistency (Ra≤0.05μm)

- Adaptive Capacity: Handles 300x300mm to 2500x1800mm sizes and 3-25mm thicknesses

- Profile Versatility: Instant switching between pencil/C-edge configurations

- High-Speed Processing: 15m/min continuous feed rate

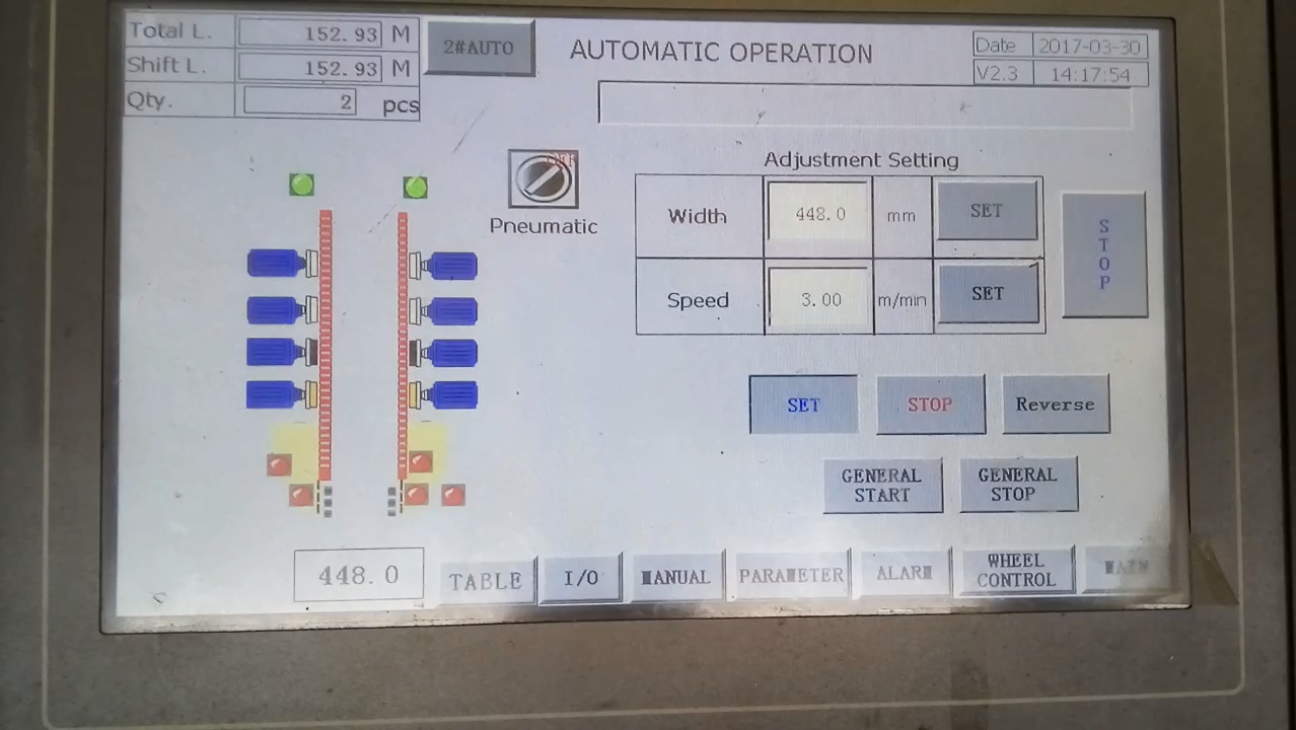

- Intelligent Control System: 10.1" touchscreen HMI with 200+ recipe storage

- Tooling System: 8-axis diamond wheel positioning with automatic wear compensation

- Safety Integration: Laser scanners + emergency brakes + fully enclosed grinding chambers

- Industrial Construction: Reinforced steel frame with IP54 protection rating

- Automated Maintenance: Self-lubricating guideways and vibration diagnostics

Product Applications

- High-End Furniture: Table tops, display cabinets, and decorative panels

- Automotive Glazing: Side windows, sunroofs, and mirror assemblies

- Architectural Systems: Balustrades, partitions, and façade elements

- Specialty Glass: Museum displays, retail fixtures, and art installations

- Safety-Critical Environments: Child-safe edges for schools/hospitals

- Integrated Production: Core component in Glass Double Pencil Edging Processing Lines

Product Advantages

- Aesthetic-Performance Fusion: Combines mirror-finish Glass Pencil Edge Grinding with 35% increased impact resistance

- Line Synchronization: Processes 140 panels/hour as Double Pencil line equipment - 45% faster than conventional systems

- Zero-Changeover Flexibility: Switch between pencil/R5-R20 C-edges in <15 seconds

- Labor Optimization: 50% reduction in operator requirements through automated calibration

- Material Conservation: 22% less glass waste via digital contour mapping

- Premium Edge Integrity: Eliminates micro-chipping (≤0.01mm defect rate)

- Energy Efficiency: 30% lower consumption than hydraulic competitors

- Operational Safety: SIL3-certified protection systems reduce accidents by 90%

- 98.5% Uptime Reliability: Predictive maintenance alerts cut downtime by 65%

- ROI Acceleration: 14-month payback period through 40% throughput increase

Technical Performance Metrics

- Edge Consistency: ±0.05mm dimensional tolerance across 2.5m panels

- Surface Quality: Ra 0.03-0.05μm without secondary polishing

- Radius Range: Standard R3-R20 profiles (custom R1-R50 available)

- Output Capacity: 140×3000×1800mm panels/hour @ 10mm thickness

- Power Consumption: 18.5kW peak / 12.2kW average

- Compressed Air: 6 bar @ 250L/min

Industry Compliance

- CE, UL, and GB standards certification

- ISO 13849-1 (PLd) safety compliance

- ANSI Z97.1 impact resistance certification

This Glass Double Pencil Edging Machine revolutionizes edge processing by unifying precision Glass Pencil Edge Grinding with C-edge versatility - reducing per-panel costs by 35% while eliminating secondary finishing operations. Its seamless integration into automated Double Pencil line configurations establishes new benchmarks for productivity in safety-critical glass manufacturing.