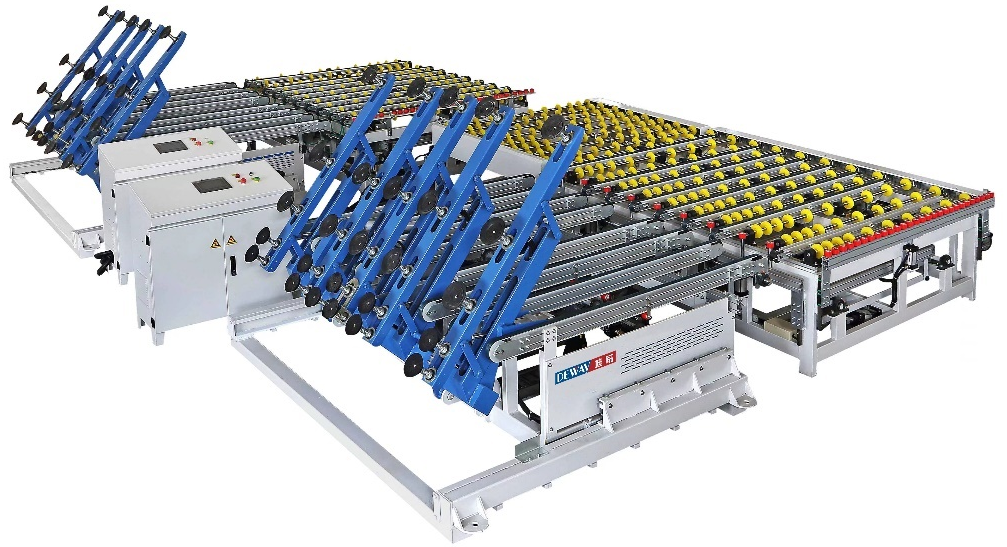

Product Introduction

The DSP2520 Automatic Glass Loading Table is an advanced solution designed to optimize glass manufacturing by automating panel loading. Engineered to handle glass sheets with precision, this Glass Loading Table ensures seamless integration into production lines while maintaining safety and quality standards. Specifically functioning as a Glass Double Edging Loading Table, it provides accurate alignment for edge processing machinery.

Product Features

- Automated transfer system significantly reducing manual labor requirements

- Precise alignment technology ensuring accurate positioning for processing equipment

- Dedicated Glass Double Edging Loading Table functionality for edge processing integration

- Programmable control system adaptable to various glass sizes and thicknesses

- Precision mechanics enabling gentle transfer of delicate/oversized panels

- Robust construction using high-quality industrial-grade materials

- Comprehensive safety systems including protective barriers, sensors, and emergency stops

Product Applications

- Transfer of glass panels from storage to processing equipment

- Architectural glass production lines

- Mirror manufacturing facilities

- Specialized glass panel handling operations

- Integration with double edging machinery for sequential processing

- High-value glass product manufacturing environments

Product Advantages

- Substantial manual labor reduction through Automatic Glass Loading Table operation

- Minimized risk of glass damage during loading procedures

- Precise panel positioning functionality as Glass Double Edging Loading Table

- Consistent production quality maintenance through accurate alignment

- Operational adaptability to diverse glass product specifications

- Enhanced protection for delicate and oversized glass panels

- Long-term operational reliability with minimal maintenance requirements

- Comprehensive operator safety protection systems

- Uninterrupted production flow maintenance capability

- High-efficiency performance of Automatic Glass Loading machine in production lines

Operational Benefits

- Streamlined manufacturing process optimization

- Integrity preservation for high-value glass products

- Consistent processing quality maintenance

- Industrial-environment durability assurance

- Workplace injury risk reduction through automation

- Production deadline compliance capability

- Large order fulfillment reliability

Technical Implementation Details

- Precision mechanical design supporting secure glass transfer

- Intelligent control system programming for dimensional adaptability

- Seamless workflow integration with downstream processing equipment

- Damage prevention technology for scratch/chip-sensitive applications

- Continuous operation capability in demanding industrial settings

- User-friendly interface reducing operational complexity

Quality Assurance

- Consistent alignment accuracy for edge processing

- Reliable performance in high-volume production environments

- Structural integrity maintenance during continuous operation

- Safety standard compliance for industrial equipment

This Glass Loading Table delivers essential reliability through precision engineering and robust construction, meeting stringent industry standards for automated glass handling systems. The DSP2520's integration as Glass Double Edging Loading Table ensures processing consistency while its Automatic Glass Loading machine capabilities optimize production efficiency across glass manufacturing applications.