Brief introduction

The DZX Glass Working Center processes any shape glass for edging, drilling, writing (engraving), and polishing. Through its automatic tool changing system, the glass requires no movement during edging, drilling, milling, and polishing operations performed with drilling bits, diamond wheels, and polishing wheels. The glass is vacuum-fixed on the working table, with software-guided positioning to assist the operator in placement. This working center utilizes a high-speed main spindle for glass processing, reaching maximum speeds up to 9000rpm, with adjustable speeds configurable to customer requirements. Featuring high-precision processing, fast operation, superior polishing, and simple operation, the machine is ideal for mass production of shaped glass, furniture glass, automotive glass, and other size-critical applications demanding stringent quality standards, requiring only one operator.

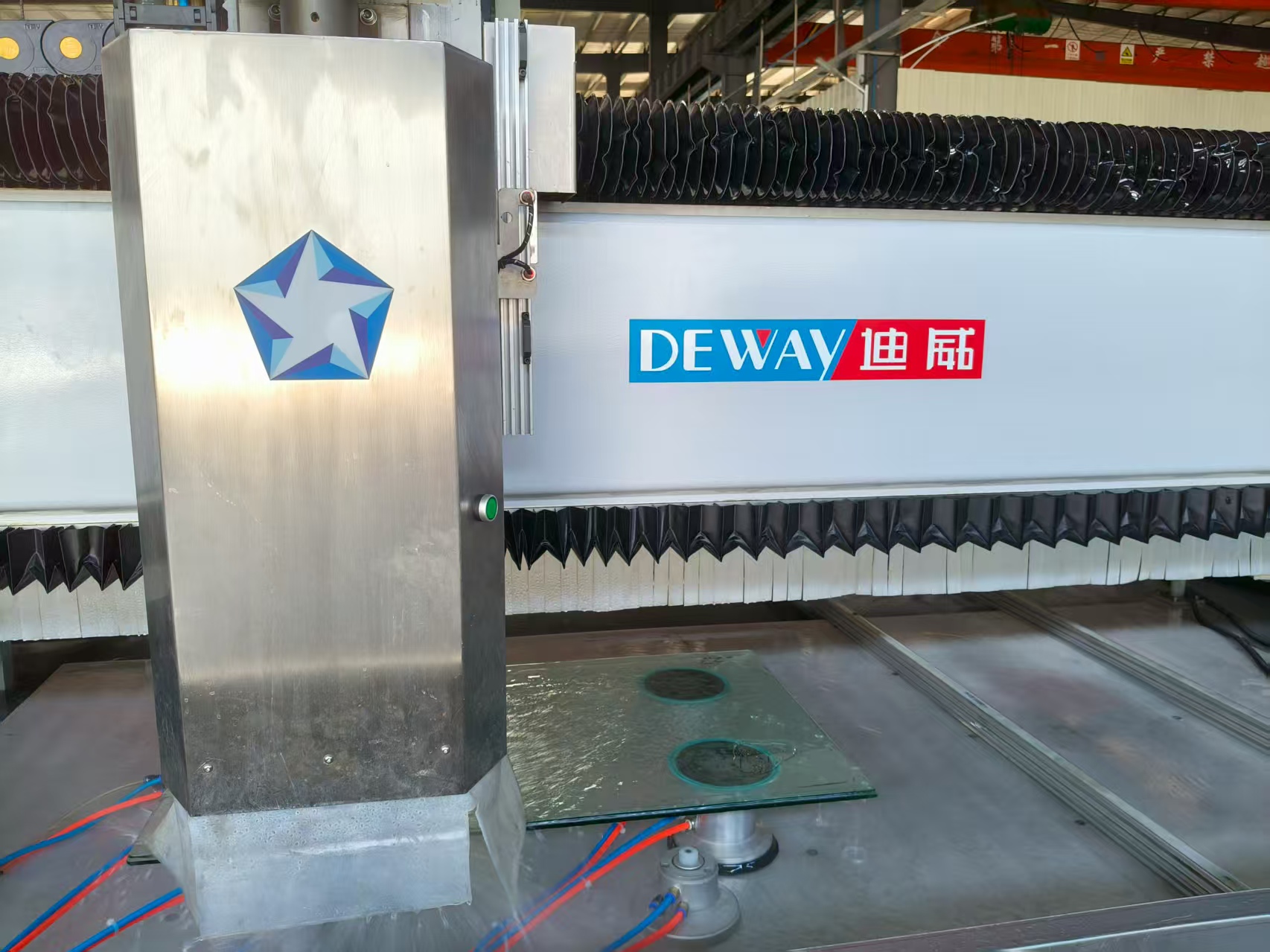

Product Introduction

The DZX3216 CNC Glass Working Center (3200x1600mm) is an advanced, all-in-one solution for large-format glass fabrication. Integrating CNC Glass Cutting Machine, CNC Glass Grinding Center, and CNC Glass Polishing Machine capabilities, it delivers precision processing for architectural, automotive, and decorative glass sectors.

Product Features

- Large-Format Capacity: 3200x1600mm work area for oversized panels

- Multifunctional: Seamlessly transitions between cutting, grinding, and polishing

- Robust Construction: Heavy-duty frame ensures operational stability

- Precision Engineering: High-speed spindle & linear guides for micron-level accuracy

- Automated Systems: Includes automatic tool changers and integrated dust extraction

- User-Friendly CNC: Intuitive programming interface reduces setup time

Product Applications

- Architectural glass (facades, partitions)

- Automotive windshields & windows

- Decorative glass panels

- Specialty glass components

Product Advantages

Unified Workflow: Eliminates material handling between processes as a combined CNC Glass Cutting Machine, CNC Glass Grinding Center, and CNC Glass Polishing Machine

Big-Size Expertise: As a dedicated CNC Glass processing Machine for big size, handles large panels with unmatched consistency

Enhanced Productivity: 30% faster cycle times vs. standalone machines

Premium Finish: Superior edge quality (Ra ≤ 0.1μm) and optical clarity

Cost Efficiency: Energy-saving design reduces power consumption by 25%

Safety Compliance: Full protective enclosure meets CE/OSHA standards

This CNC Glass Working Center optimizes large-scale production with ≤0.1mm tolerance, slashing processing costs while maintaining flexibility for complex designs.

Main technical data

v Max. Processing glass size:3200×1600mm;

v Processing thickness:3~25 mm

v Axis stroke(X,Y,Z): 2700, 1600, 200mm

v Max. Speed for X、Y、Z: 37/30/10m/min

v Max. speed for spindle:9000rpm

v Main spindle:7.5kw

v Max. Diameter for the wheel:φ100

v Tool rack:12

v Total power:17.5kw

v Overall size(X、Y、Z): 6600×2850×2200mm;

v Gross weight:6500kg

v Finished tolerance:±0.150mm