Brief introduction

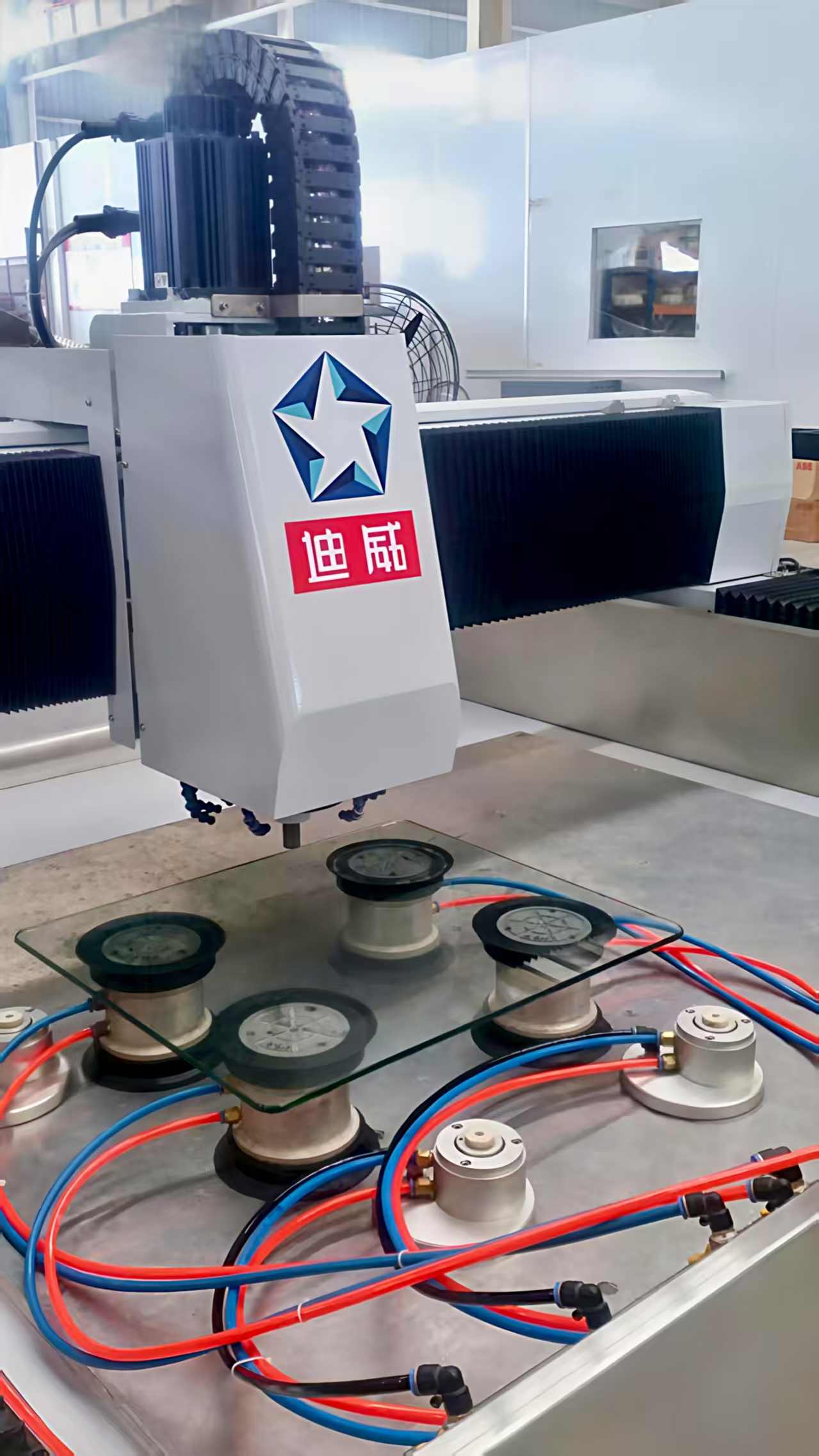

DZX glass working center can be used for any shape glass edging, drilling, writing, polishing, through auto tools changing system, there is no need to move the glass to process the edging, drilling, milling, and polishing by the drilling bit, diamond wheel, polishing wheels. The glass is fixed by vacuum on the working table, and through the software to fix the position to guide the operator to place the glass.

The glass working center is using the high speed main spindle for the glass process, the max. Speed is up to 9000rpm. And it can be set different speed according to customer’s requirement.

This working center with the features of high precision processing, fast speed, good polishing and easy operate, the machine is suitable for mass production for shape glass processing, furniture glass, car glass and other size which has high requirement for different usage. The machine needs only one person to operate.

DZX1512 CNC Working Center (1500x1200mm): Product Introduction

The DZX1512 is a highly advanced Automatic glass processing machine designed for demanding Home Appliance Glass processing and Auto Glass Processing Center applications. This CNC Working Center features a large 1500x1200mm work area for precise handling of substantial glass sheets.

Key Features:

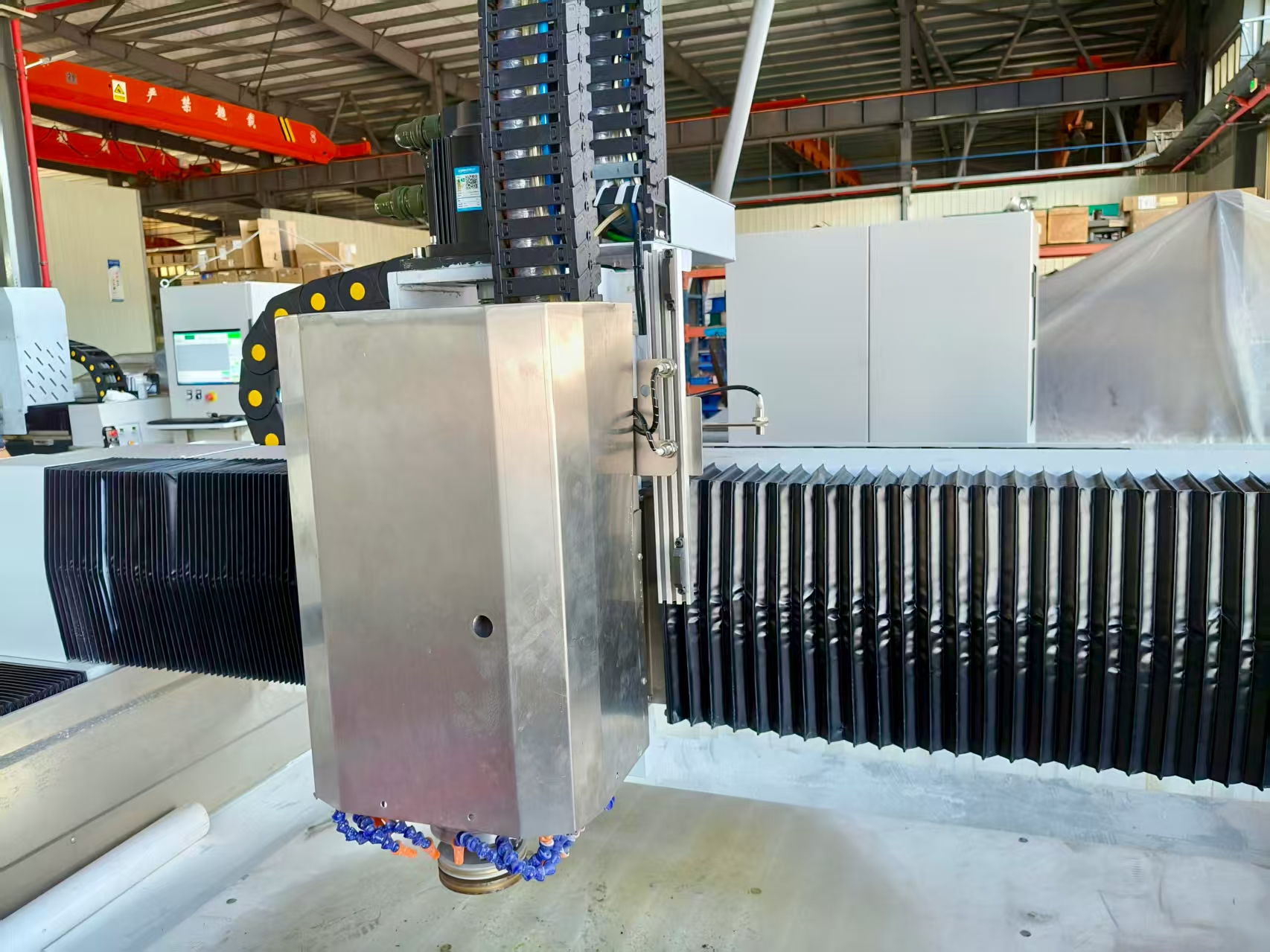

Multifunctional Processing: Integrates cutting, grinding, and polishing within one Automatic glass processing machine.

Advanced CNC System: Ensures precise control for complex shapes and consistent quality.

Robust Grinding Tools: Handles various glass thicknesses effectively.

High Automation: Minimizes manual intervention throughout operations.

User-Friendly Interface: Accessible for operators of varying skill levels.

Primary Applications:

Home Appliance Glass Grinding & Processing: Essential for Home Appliance Glass Grinding of edges and surfaces on components like refrigerator shelves and microwave doors. Handles diverse Home Appliance Glass processing needs efficiently.

Auto Glass Processing Center: Functions as a dedicated Auto Glass Processing Center for complex automotive components (windshields, side windows), performing grinding, drilling, and polishing.

Key Benefits:

Enhanced Efficiency: Single-machine multitasking (cut/grind/polish) significantly reduces cycle times.

Superior Quality & Consistency: The CNC Working Center's precision ensures high, repeatable quality meeting stringent standards for both home appliance and automotive glass.

Reduced Error: Automation inherent in this Automatic glass processing machine minimizes human error.

High Volume Production: Automated design enables sustained high output with tight tolerances.

Versatility: Suitable for diverse Home Appliance Glass processing and Auto Glass Processing Center tasks.

Streamlined Workflow: Performs multiple operations in one continuous cycle, often eliminating secondary processing.

Overall: The DZX1512 CNC Working Center is a versatile, reliable Automatic glass processing machine, crucial for high-quality Home Appliance Glass Grinding, Home Appliance Glass processing, and Auto Glass Processing Center applications.

Name plate

Machine’ s name:Glass CNC Machining center

Model:DZX1512

Power Supply:380V, 50Hz

Total power:14.5Kw

Glass thickness:3~8mm

Max. Glass Size: 1450x1120

Weight:2100kg

Serial Number:

Production date:2020

Technical data

Model no. | DZX1210 | DZX1512 | |

1 | Max. glass size [mm] | 1150×920 | 1450×1120 |

2 | Glass thickness [mm] | 3-8 | 3-8 |

3 | Path of the axis(X、Y、Z) [mm] | 1370,1150,100 | 1700,1400,150 |

4 | Max. speed of the axis(X、Y、Z) [m/min] | 15,15,7.5 | |

5 | Processing speed [m/min] | 0.5~8 | |

6 | Main spindle max. speed [rpm] | 9000 | |

7 | Main spindle power [Kw] | 7.5 | |

8 | Tool rack (Optional) [pcs] | 0 | 6 |

9 | Max. Diameter for the wheels [mm] | 100 | |

10 | Max. Overall size [mm] | 3300×2200×2200 | 3600×2450×2200 |

11 | Gross weight [kg] | 1800 | 2100 |

12 | Pressed air [bar] | 6.5 | |

13 | Qty. for the water tank [pcs] | 2 | |

14 | Voltage [V] | See the diagram | |

15 | Total power [kw] | 14.5 | |