Brief introduction

DZX Glass Working Center Capabilities:

Processes any glass shape for edging, drilling, engraving ("writing"), and polishing. Its automated tool-changing system (drilling bits, diamond wheels, polishing wheels) performs all operations without repositioning the glass.

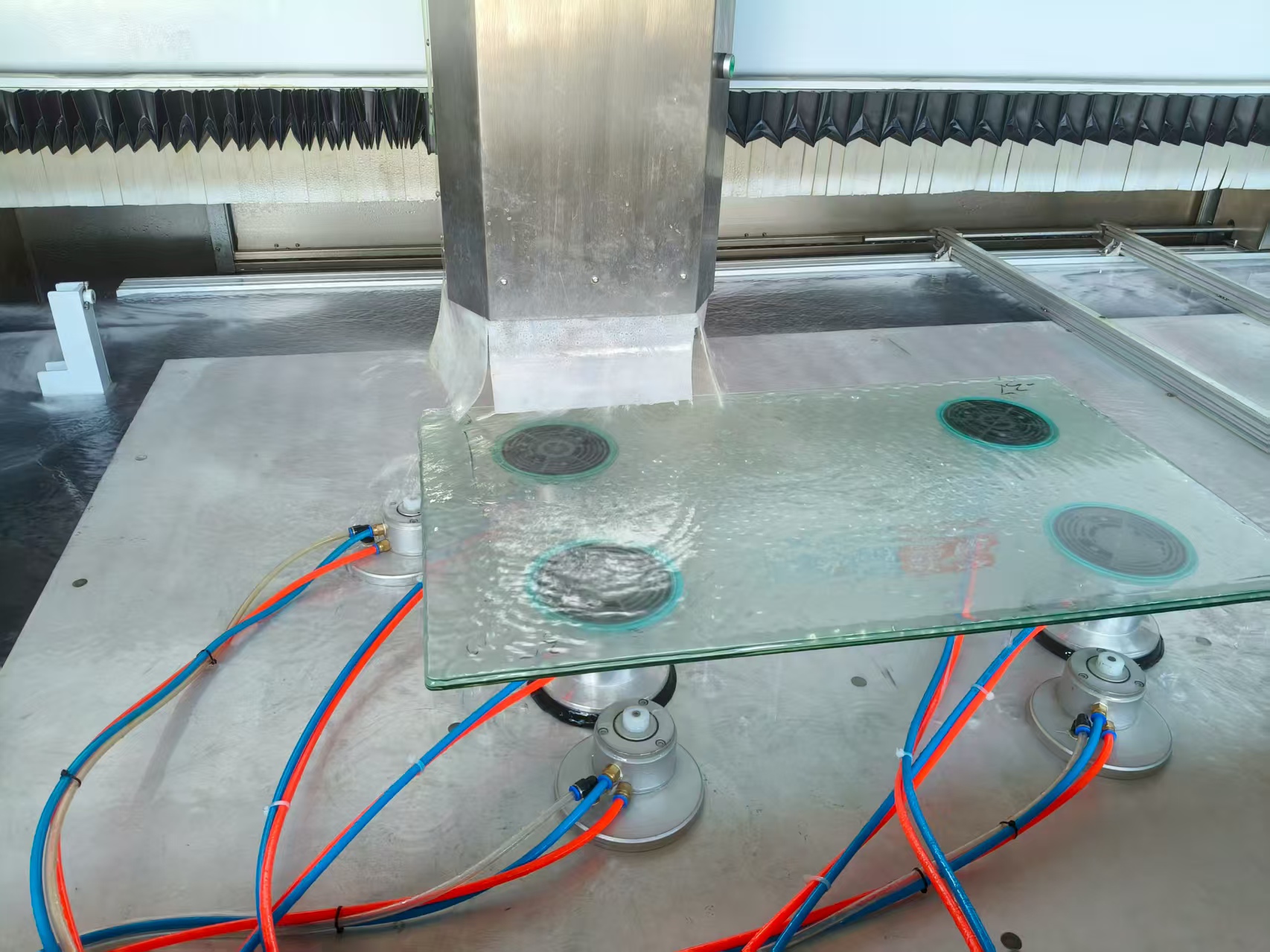

The glass is securely fixed by vacuum on the work table. Positioning software guides operators during glass placement.

This center employs a high-speed spindle for glass processing, with a maximum speed of 9000 rpm. Spindle speed is adjustable per customer requirements.

Featuring high-precision processing, rapid operation, quality polishing, and simple operation, the machine suits mass production of shaped glass, furniture glass, automotive glass, and other high-precision applications. Requires only one operator.

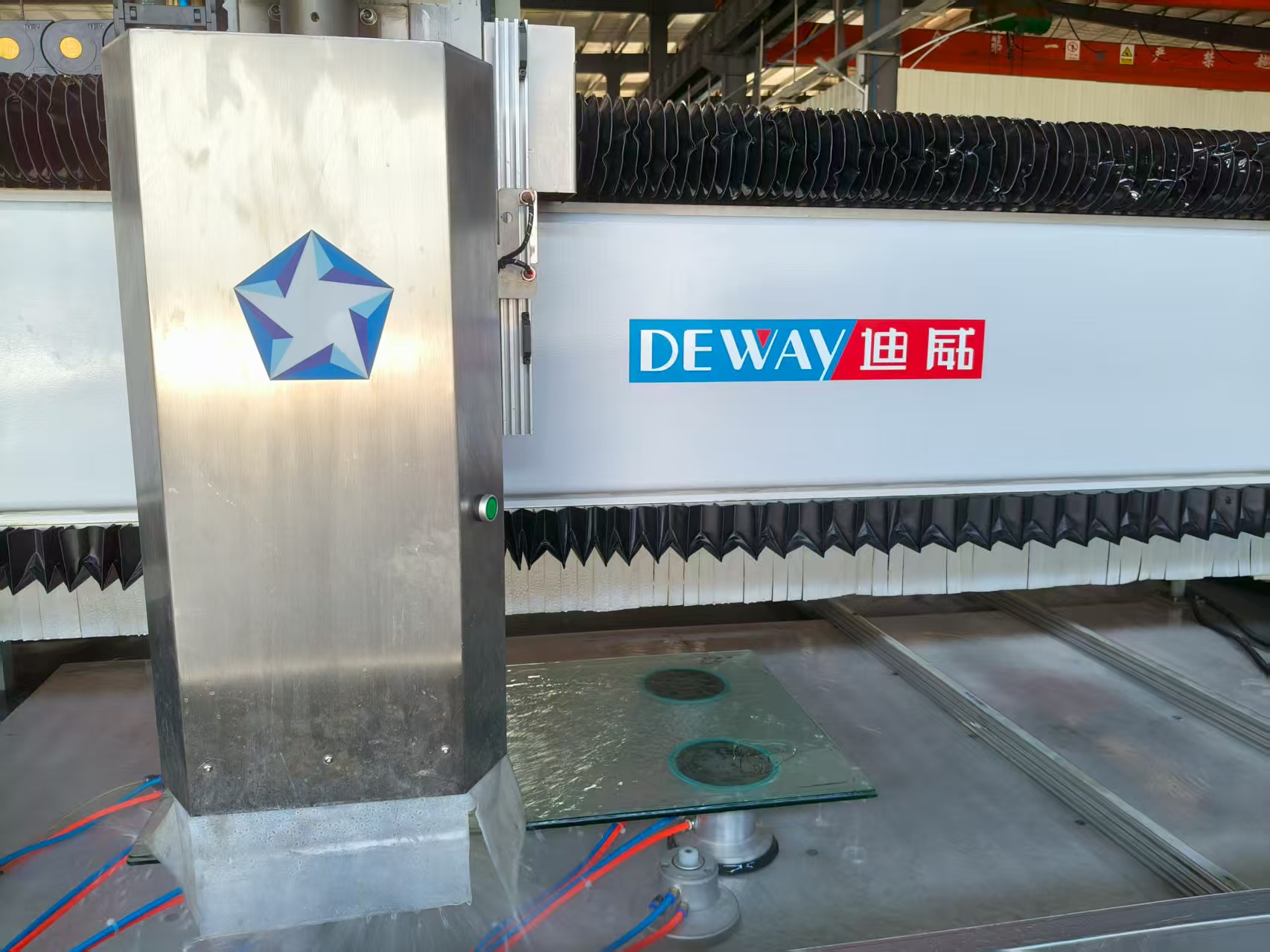

DZX2512 CNC Glass Machining Center (2500x1200mm): Product Introduction

The DZX2512 represents precision engineering for high-performance glass fabrication. This versatile CNC Glass Machining Center handles medium-to-large panels (2500x1200mm) for architectural, automotive, and interior design applications.

Key Features:

Advanced CNC Control: Ensures precision across milling, drilling, and polishing

Multi-Function Design: Integrates capabilities as both a CNC Glass Machining Machine and specialized processor

High-Speed Machining: Precision spindle for efficient material removal

Robust Construction: High-precision linear guides ensure stability

Safety Systems: Includes automatic tool changers, dust extraction, and protective enclosures

Primary Applications:

Precision Milling & Polishing: Functions as a CNC Glass Polishing Machine for milling to achieve flawless surface finishes.

Structural Glass Drilling: Operates as a CNC Glass Processing machine for drilling exact holes in shower enclosures, balustrades, and structural components.

Complex Component Fabrication: Executes intricate designs for automotive and architectural glass.

Key Benefits:

Unified Processing: Combines milling, drilling, and polishing in one CNC Glass Machining Center

Production Efficiency: Reduces manual intervention and errors while boosting output

Superior Finish Quality: Delivers precise edges and polished surfaces meeting industry standards

Material Versatility: Handles diverse glass thicknesses for multiple applications

Operational Safety: Integrated protection systems maintain a secure workspace

Energy Efficiency: Eco-conscious design reduces power consumption

Overall: The DZX2512 CNC Glass processing Machine (2500x1200mm) is an indispensable CNC Glass Machining Machine for professional fabrication. Its dual capability as a precision CNC Glass Polishing Machine for milling and dedicated CNC Glass Processing machine for drilling makes it essential for high-quality production.

Name plate

Machine’s name:Glass CNC Machining center

Model: DZX2512

Power Supply:380V, 50Hz

Total power:17.5Kw

Glass thickness:3~25mm

Max. Glass Size: 2500x1200

Weight:5500kg

Serial Number:

Production date:2016

Main technical data

v Max. Processing glass size:2500×1200mm;;

v Processing thickness:3~25 mm

v Axis stroke(X,Y,Z): 2700, 1600, 200mm

v Max. Speed for X、Y、Z: 37/30/10m/min

v Max. speed for spindle:9000rpm

v Main spindle:7.5kw

v Max. Diameter for the wheel:φ100

v Tool rack:12

v Total power:17.5kw

v Overall size(X、Y、Z):5000×2450×2200mm;

v Gross weight:5500kg;

v Finished tolerance:±0.150mm