PRODUCT INTRODUCTION

The DXM471B Glass Straight-line Bevelling Machine bearing conveyor represents a highly advanced and exceptionally reliable solution engineered specifically for precision glass processing applications focused on straight-line bevelling operations. This sophisticated equipment incorporates an integrated bearing conveyor system, fundamentally designed to ensure optimally smooth, stable, and vibration-minimized transportation of glass sheets throughout the entire bevelling process. This Glass Straight-line beveller with bearing conveyor mechanism guarantees consistent physical contact with the glass surface, critically enhancing the quality of finished bevelled edges. The system delivers uniformly clean, professionally polished finishes that rigorously satisfy the most demanding quality standards prevalent throughout the global glass manufacturing and processing industry.

---

PRODUCT FEATURES

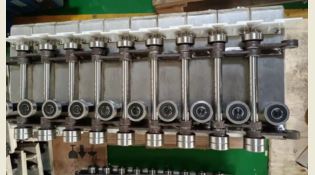

1. High-Capacity 12-Spindle Processing Configuration:

Each of the twelve precision spindles undergoes meticulous calibration to operate with exacting accuracy. This advanced multi-spindle engineering facilitates the simultaneous, high-efficiency processing of numerous glass panes, accommodating significant variations in both glass thickness and dimensional size parameters. This configuration is essential for guaranteeing edge uniformity and geometric consistency across all processed units, eliminating batch variation.

2. Integrated Ball Bearing Conveyor Technology:

The defining characteristic of this Glass Bevelling machine with ball bearing is its specialized conveyor system incorporating high-grade ball bearings. These precision-engineered bearings dramatically reduce operational friction between moving components, directly contributing to enhanced mechanical longevity, sustained operational stability over extended production runs, and significant reductions in long-term maintenance frequency and associated costs.

3. Bearing Conveyor System (BCS) for Enhanced Stability:

The core Glass Straight-line Bevelling Machine bearing conveyor functionality ensures glass substrates remain perfectly stable and free from detrimental vibrations during transit through the machining zone. This continuous, controlled movement is paramount for maintaining unvarying contact pressure and alignment against the bevelling spindles, directly translating to superior edge quality and dimensional precision.

4. Robust Construction with User-Centric Interface:

Engineered for durability and operational simplicity, the machine features an intuitively designed control interface alongside a heavy-duty frame construction. This robust build quality enables reliable handling and processing of an exceptionally broad spectrum of glass types, ranging from standard float glass to more complex coated variants and laminated safety glass composites.

---

PRODUCT APPLICATIONS

Precision Bevelling for Reflective Surfaces:

The Mirror beveller with ball bearing capability is particularly optimized for demanding applications requiring flawless bevels on mirrors and other high-reflectivity glass products. The ball bearing conveyor technology provides the necessary micron-level control over glass positioning and feed rate during the critical bevelling operation. This precise control is indispensable for achieving the exact angular specifications and optically perfect, scratch-free surface finishes mandated for premium mirror applications.

Versatile Glass Substrate Processing:

The machine demonstrates exceptional versatility, efficiently processing standard clear and tinted float glass, various types of coated glass (including low-E and solar control variants), and laminated glass assemblies. Its scalability makes it equally suitable for small boutique workshops requiring high-quality bespoke pieces and large-scale industrial manufacturing facilities focused on high-volume output.

---

PRODUCT ADVANTAGES

1. Uncompromising Edge Quality and Consistency:

The synergistic integration of the Glass Straight-line beveller with bearing conveyor stability with the precision of 12 calibrated spindles guarantees the production of consistently flawless, high-gloss polished bevels on every processed glass sheet, batch after batch, meeting stringent aesthetic and functional requirements.

2. Significant Throughput and Operational Efficiency:

The multi-spindle (12-spindle) architecture enables the concurrent processing of multiple glass units, dramatically boosting production capacity and overall operational efficiency without any compromise on the precision or quality of the bevelled edge finish.

3. Superior Performance on Delicate Mirror Surfaces:

Functioning as a dedicated Mirror bearing beveller, the machine delivers unmatched precision specifically for mirror finishing tasks. The ball bearing conveyor ensures gentle, accurate handling, preserving the integrity of delicate reflective coatings and backings while achieving the exact bevel geometry required for high-end mirror products.

4. Extended Machinery Lifespan and Reduced Maintenance:

The incorporation of ball bearing technology within the conveyor system significantly diminishes internal friction and mechanical wear on critical components. This engineering choice directly results in prolonged operational life for the entire machine structure and substantially lowers both the frequency and cost of essential maintenance interventions and part replacements.

5. Exceptional Adaptability Across Production Environments:

The machine's inherent robust design, coupled with its ability to reliably process a diverse array of glass types (standard float, coated, laminated) and accommodate varying sizes and thicknesses, makes it a supremely adaptable asset capable of performing reliably within vastly different production scales and operational settings.

---

SUMMARY

The DXM471B Glass Straight-line Bevelling Machine bearing conveyor stands as a premier solution in the glass finishing sector. By combining the inherent stability of its bearing conveyor system, the high productivity enabled by its 12-spindle configuration, and the precision-enhancing ball bearing technology, this machine delivers exceptional, consistent performance in straight-line bevelling. Whether tasked with processing standard architectural glass sheets or executing the demanding precision required for high-quality mirrors, this Mirror bearing beveller consistently produces superior, reliable results in all glass edge finishing operations.