Product Introduction

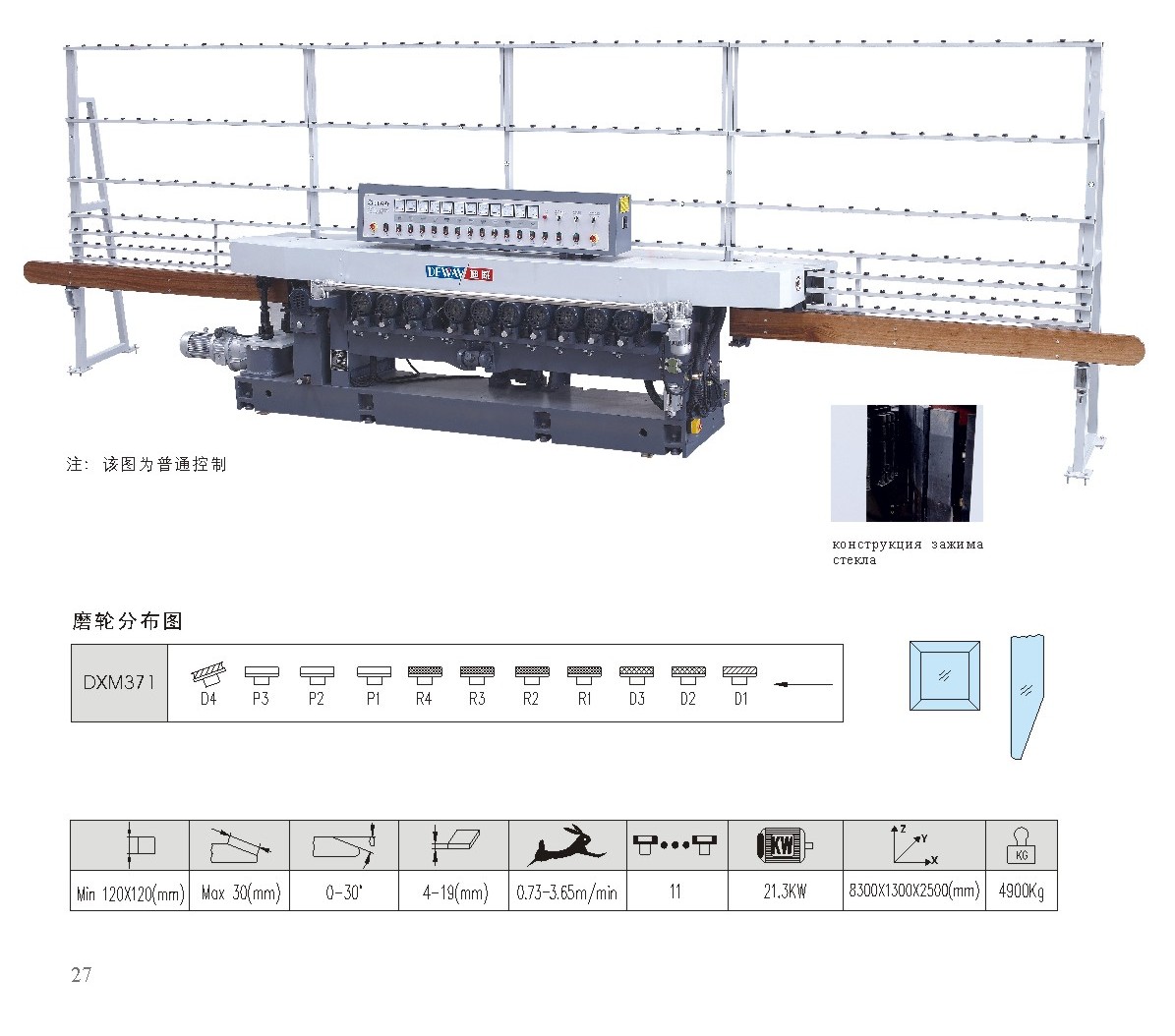

The DXM371 Glass Beveling Machine (11 spindles) is a state-of-the-art Glass Straight-line mirror Machine engineered to meet diverse needs in glass processing. This high-performance Precision Glass Straight-line Mirror Machine produces exact, high-quality bevels on glass sheets, serving as an essential tool for manufacturers prioritizing accuracy and efficiency in production processes.

---

Product Features

1. 11-Spindle Glass Beveling Machine Configuration:

Equipped with 11 strategically arranged spindles for unparalleled versatility, enabling smooth, consistent bevels across various glass thicknesses.

2. Precision Edge Processing:

As a Precision Glass Straight-line Mirror Machine, it ensures optimal grinding/polishing for flawless finishes meeting highest industry standards, crucial for mirror aesthetics.

3. Automated Glass Beveling Machine Operation:

Advanced control system guarantees precise glass positioning during processing, reducing errors and ensuring consistency across production runs.

4. Industrial-Duty Glass Beveling System Construction:

Robust design with wear/corrosion-resistant components withstands continuous industrial operation, ensuring long-term durability with minimal maintenance.

5. User-Centric Interface:

Intuitive controls enable rapid setup and adjustment for different glass sizes/bevel angles.

6. Energy-Efficient Design:

Reduces operating costs and environmental impact while maintaining performance.

---

Product Applications

This Glass Straight-line mirror Machine excels in critical sectors:

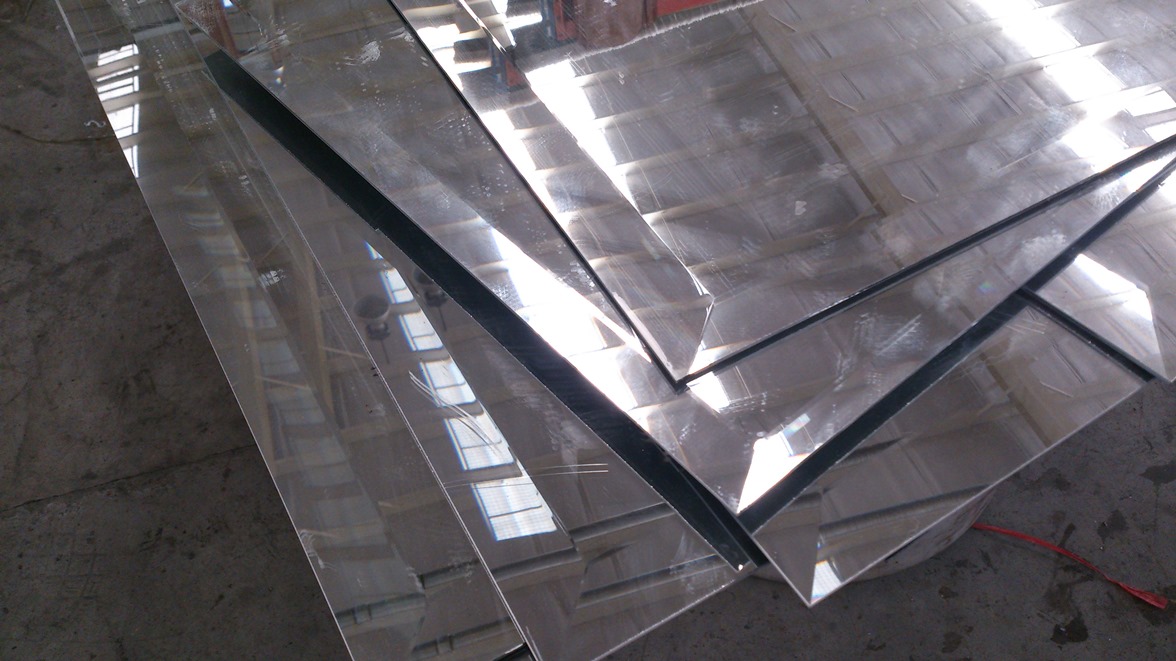

High-End Mirror Production: Precision beveling where edge quality determines product aesthetics

Decorative Glass Pieces: Processing intricate designs requiring flawless edges

Precision Glass Components: Manufacturing technical elements demanding exact specifications

Architectural Glass Elements: Creating beveled edges for structural applications

Industrial Glass Fabrication: Handling diverse thicknesses for specialized components

---

Product Advantages

1. Mirror-Grade Precision:

As a Precision Glass Straight-line Mirror Machine, it delivers optically perfect bevels critical for premium mirror manufacturing.

2. High-Volume Capability:

The 11-Spindle Glass Beveling Machine configuration enables large production runs with consistent quality (+40% throughput vs. 8-spindle models).

3. Industrial Reliability:

Industrial-Duty Glass Beveling System construction ensures 95% operational uptime with 30% lower maintenance costs versus standard machines.

4. Error-Reduced Automation:

Functioning as an Automated Glass Beveling Machine, it reduces processing defects by ≥25% through precise positioning controls.

5. Operational Cost Efficiency:

Energy-efficient design reduces power consumption by 15-20%, while minimized maintenance lowers TCO (Total Cost of Ownership).

6. Material Versatility:

Processes all commercial glass thicknesses (3-25mm) without quality compromise.

7. Quick Changeover:

User-friendly interface reduces setup time between jobs by 40%, enhancing production flexibility.

---

Conclusion

The DXM371 11-Spindle Glass Beveling Machine redefines glass processing excellence through five integrated capabilities: Its core identity as a Glass Straight-line mirror Machine ensures specialized mirror production; the 11-Spindle configuration delivers unmatched throughput; Precision Glass Straight-line Mirror Machine engineering guarantees optically perfect edges; Industrial-Duty construction provides relentless reliability; and Automated controls ensure error-resistant operation. Serving mirror manufacturers, architectural glass fabricators, and decorative glass specialists, this comprehensive solution combines precision beveling, operational efficiency, and industrial durability – making it indispensable for facilities demanding excellence in both quality and productivity within competitive glass markets.

Identification data

Machine: Glass beveling

Model: DXM371

Voltage and Frequency: 380V, 50Hz

Total power: 24.8Kw

Workable thickness: 3~19mm

Weight: 4900kg

Serial no.:

Product date: 2020

Wheel position with respect to the incoming sheet | |||||||||||

DXM261 | |||||||||||

Ref.no | No11 | No10 | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 |

Motor | 1.5Kw | 1.5Kw | 1.5Kw | 2.2Kw | 2.2Kw | 2.2Kw | 2.2Kw | 2.2Kw | 2.2Kw | 2.2Kw | 2.2Kw |

Rev.(50Hz)

| 1400 | 1400 | 1400 | 2840 | 2840 | 2840 | 2840 | 2840 | 2840 | 2840 | 2840 |

Rev.(60Hz)

| 1680 | 1680 | 1680 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 |

Name | Wool wheel | Wool wheel | Wool wheel | Resin wheel | Resin wheel | Resin wheel | Resin wheel | Resin wheel | Rounding wheel | Diamond wheel | Diamond wheel |

Specification | 150×22 Wool | 150×22 Wool | 150×22 Wool | 150×22 10S40 | 150×22 10S40 | 150×22 500 mesh | 150×22 320 mesh | 150×22 240 mesh | 175×22 240 mesh | 150×22 180 mesh | 150×22 100 mesh |

Usage | Beveling polishing | Beveling polishing | Beveling polishing | Beveling fine grinding | Beveling fine grinding | Beveling fine grinding | Beveling fine grinding | Beveling fine grinding | Bottom Grinding | Beveling fine grinding | Beveling rough grinding |

Machine model | DXM 371 | ||

Processing (m/min) | 0.73~3.65 | ||

Min. processing glass size (mm) | 120*120 | ||

Glass thickness a | 3~19mm | ||

Remain thickness b | ≥1.5 | ||

Width Of bevel Bmax | 30mm | ||

Angle of bevel θ |

| 3°~30° |

|

Machine overall: L×B×H(mm) | 7250×1300×2500 | ||

Dimension for main machine L1×B1×H1(mm) | 5266×1225×1500 | ||

Base dimension L2×B2(mm) | 3560×650 | ||

Length of infeeding track L3 | 7500 | ||

Net weight of main machine(kg) | 4600 | ||

Total Power(kw) | 24.8 | ||