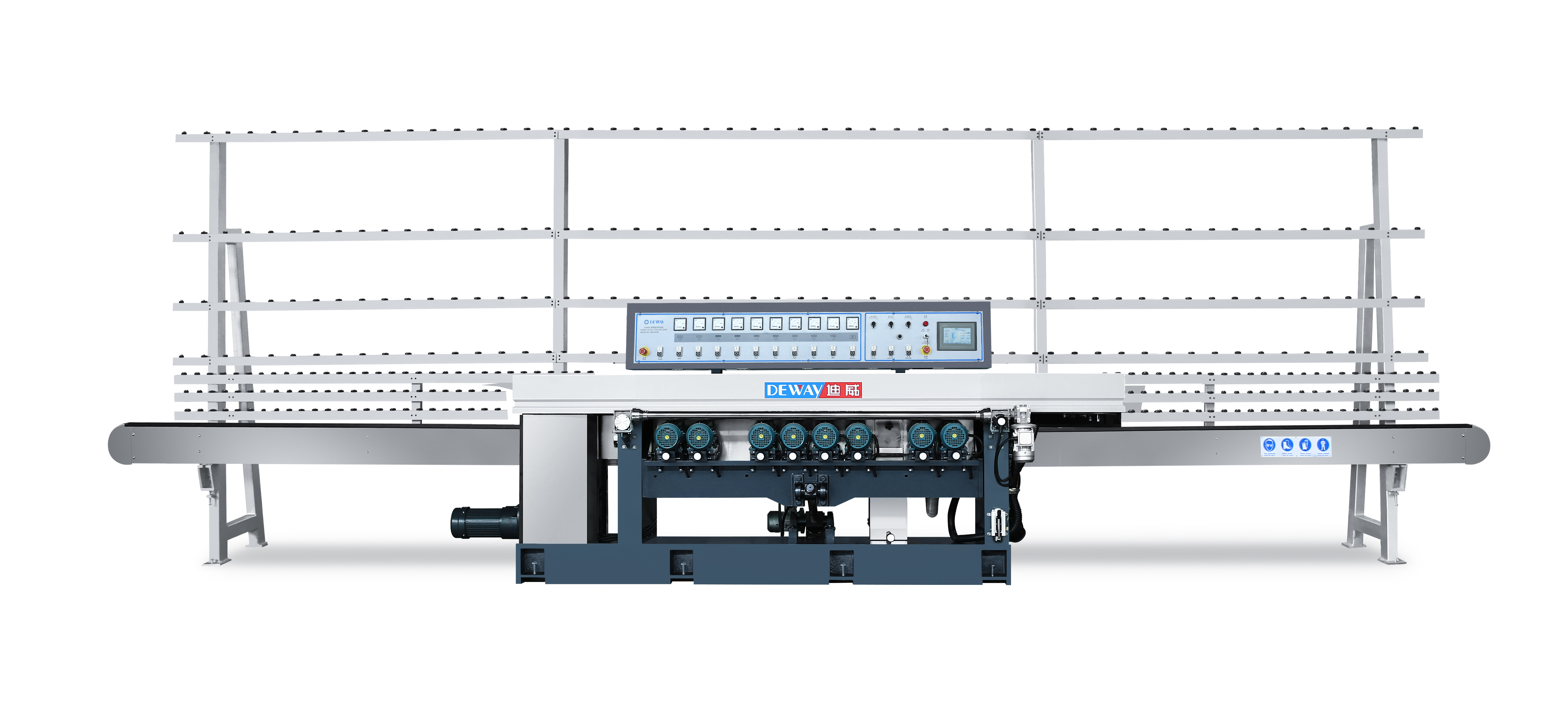

Product Introduction

The DXM261 Glass Beveling Machine (9 spindles) represents the pinnacle of innovation as a High-Precision Glass Beveller. Engineered for impeccable beveling on flat glass surfaces, it caters to demanding industries including architectural glass, automotive glass, and decorative glass manufacturing. This cutting-edge solution delivers superior edge finishing through advanced engineering.

---

Product Features

1. 9-Spindle Glass Beveling Machine Configuration:

Equipped with 9 strategically arranged spindles operating in synchronized manner to ensure consistent, smooth bevels with superior finish quality.

2. Synchronized-Spindle Glass Beveller Operation:

Spindles work in unison for enhanced accuracy and faster processing times, ideal for large-scale production environments.

3. Multi-Thickness Glass Beveling System:

Handles glass thicknesses from thin sheets (mirrors/decorative items) to thick robust applications through adjustable bevel angle/width settings.

4. Heavy-Duty Glass Bevelling Machine Construction:

Frame built with high-quality materials providing stability and wear resistance under continuous operation. Spindles feature robust bearings and seals for extended operational life.

5. Intuitive Digital Control System:

User-friendly interface enables real-time parameter input and performance monitoring, reducing operator learning curve.

6. Integrated Safety Mechanisms:

Includes emergency stop functions, protective guards, and operational sensors to prevent accidents.

7. Modular Maintenance Design:

Easily accessible components facilitate quick routine checks and part replacements.

---

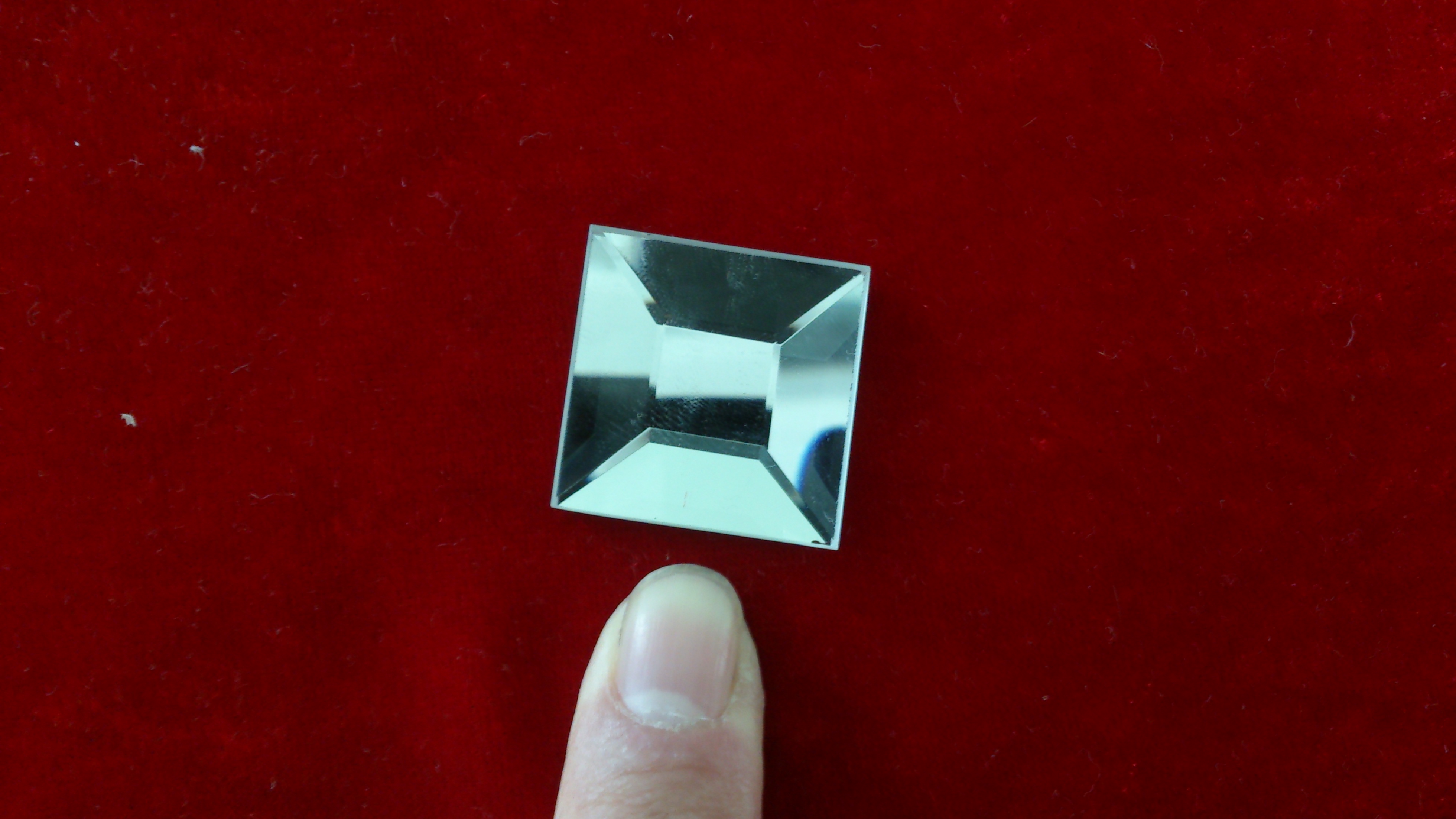

Product Applications

This Multi-Thickness Glass Beveling System serves critical applications:

Architectural Glass: Precision beveling for building facades and structural elements

Automotive Glass: Edge finishing for specialized vehicle glass components

Decorative Glass Manufacturing: High-quality bevels for artistic and interior design pieces

Mirror Production: Flawless edge processing for residential/commercial mirrors

Industrial Glass Components: Robust beveling solutions for heavy-duty applications

---

Product Advantages

1. Unmatched Precision:

As a High-Precision Glass Beveller, it guarantees impeccable edge finishes critical for aesthetic and structural integrity.

2. High-Volume Production Capability:

The 9-Spindle Glass Beveling Machine configuration enables faster processing with consistent quality for large-scale operations.

3. Material Versatility:

The Multi-Thickness Glass Beveling System adapts seamlessly across glass types (3-19mm) with minimal downtime during product changeovers.

4. Industrial Durability:

Heavy-Duty Glass Bevelling Machine construction ensures reliable performance under continuous operation, minimizing maintenance interruptions.

5. Consistent Finish Quality:

Synchronized-Spindle Glass Beveller operation delivers uniform bevels across all processed edges.

6. Operator Safety & Efficiency:

Integrated safety systems and intuitive controls enable secure operation by personnel of varying experience levels.

7. Reduced Downtime:

Modular design enables swift maintenance, sustaining optimal production rates and machine longevity.

8. Technical Performance Assurance:

Precise speed control and wide angle capability ensure exact specification adherence.

---

Conclusion

The DXM261 9-Spindle Glass Beveling Machine stands as a premier industrial solution, integrating five critical capabilities: As a High-Precision Glass Beveller, it delivers impeccable edge quality; its Synchronized-Spindle operation ensures consistent finishes; the Multi-Thickness Glass Beveling System provides unmatched adaptability; and Heavy-Duty construction guarantees reliability. Serving architectural, automotive, and decorative glass sectors, this machine excels in precision, efficiency, and operational safety – making it indispensable for manufacturers prioritizing quality and productivity in competitive glass processing markets.

Identification data

Machine:Glass beveling

Model:DXM261

Voltage and Frequency:380V, 50Hz

Total power:21.1Kw

Workable thickness:3~19mm

Weight:4500kg

Serial no.:

Product date:2016

Wheel position with respect to the incoming sheet | |||||||||

DXM261 | |||||||||

Ref.no | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 |

Motor | 1.5kW | 1.5kW | 1.5kW | 2.2kW | 2.2kW | 2.2kW | 2.2kW | 2.2kW | 2.2kW |

Rev.(50Hz) | 1400 | 1400 | 1400 | 2840 | 2840 | 2840 | 2840 | 2840 | 2840 |

Rev.(60Hz) | 1680 | 1680 | 1680 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 |

Name | Wool wheel | Wool wheel | Resin wheel | Resin wheel | Resin wheel | Resin wheel | Rounding wheel | Diamond wheel | Diamond wheel |

Specification | 150×22 Wool | 150×22 Wool | 150×70x30 10S40 | 150×22 500 mesh | 150×22 320 mesh | 150×22 240 mesh | 175×22xR5 240 mesh | 150×22 180 mesh | 150×22 100 mesh |

Usage | Beveling polishing | Beveling polishing | Beveling fine grinding | Beveling fine grinding | Beveling fine grinding | Beveling fine grinding | Bottom Grinding | Beveling fine grinding | Beveling rough grinding |

Machine model | DXM 261 | ||

Processing (m/min) | 0.73~3.65 | ||

Min. processing glass size (mm) | 120*120 | ||

Glass thickness a | 3~19mm | ||

Remain thickness b | ≥1.5 | ||

Width Of bevel Bmax | 40mm | ||

Angle of bevel θ |

| 3°~30° |

|

Machine overall: L×B×H(mm) | 7250×1300×2500 | ||

Dimension for main machine L1×B1×H1(mm) | 4866×1225×1500 | ||

Base dimension L2×B2(mm) | 3160×650 | ||

Length of infeeding track L3 | 6980 | ||

Net weight of main machine(kg) | 4500 | ||

Total Power(kw) | 21.1 | ||