Product Introduction

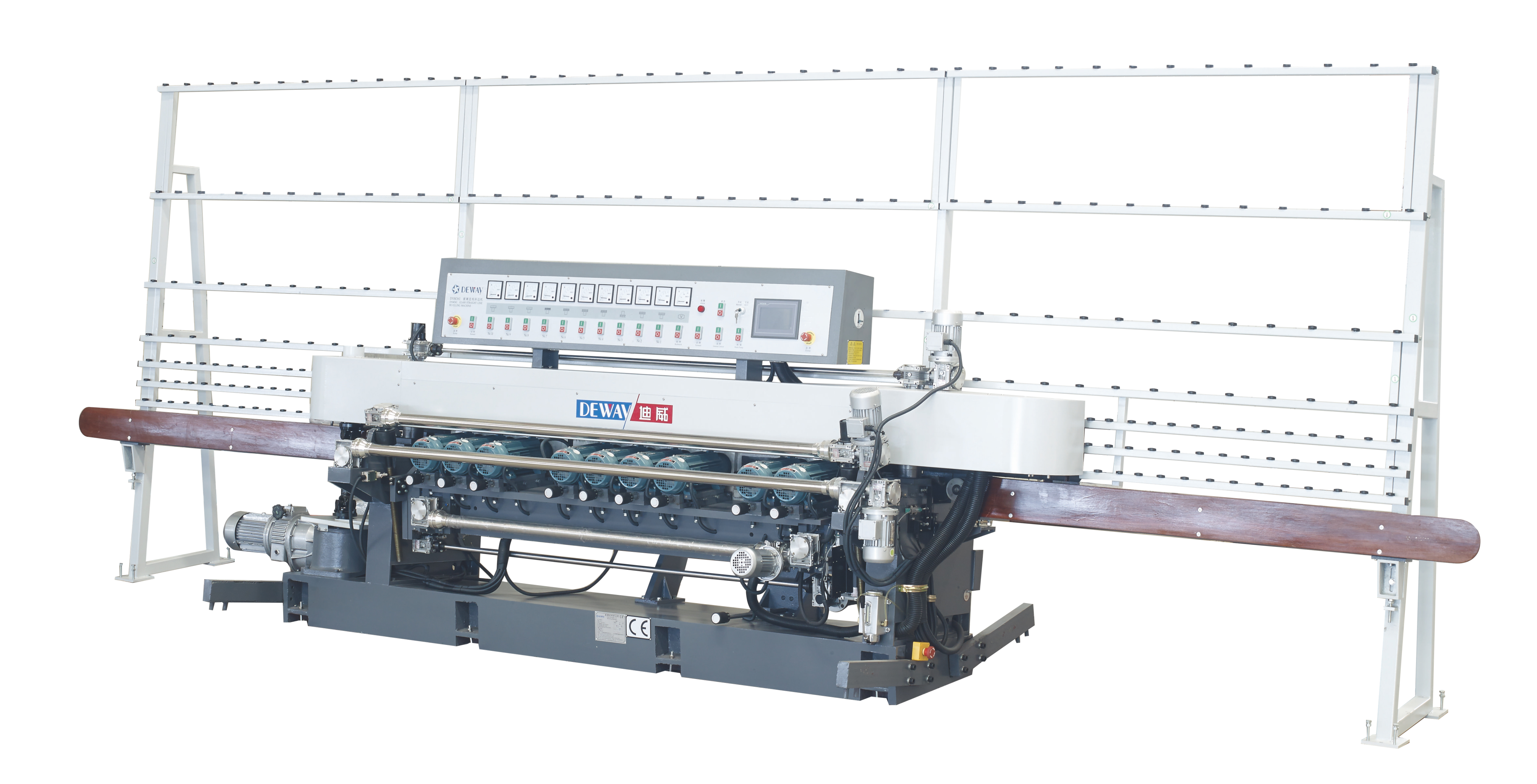

The DXM361 Glass Bevelling Machine (10 spindles) is an advanced Glass Straight-line Bevelling Machine engineered to enhance efficiency and quality in industrial glass processing. Meticulously designed for precision and consistency, it handles diverse glass types while delivering superior operational performance across applications.

---

Product Features

1. 10-Spindle Glass Bevelling Machine Configuration:

Equipped with 10 strategically positioned spindles ensuring smooth, uniform bevelling. This configuration reduces glass breakage risks and guarantees high-quality edge finishes.

2. Compact Processing Capability:

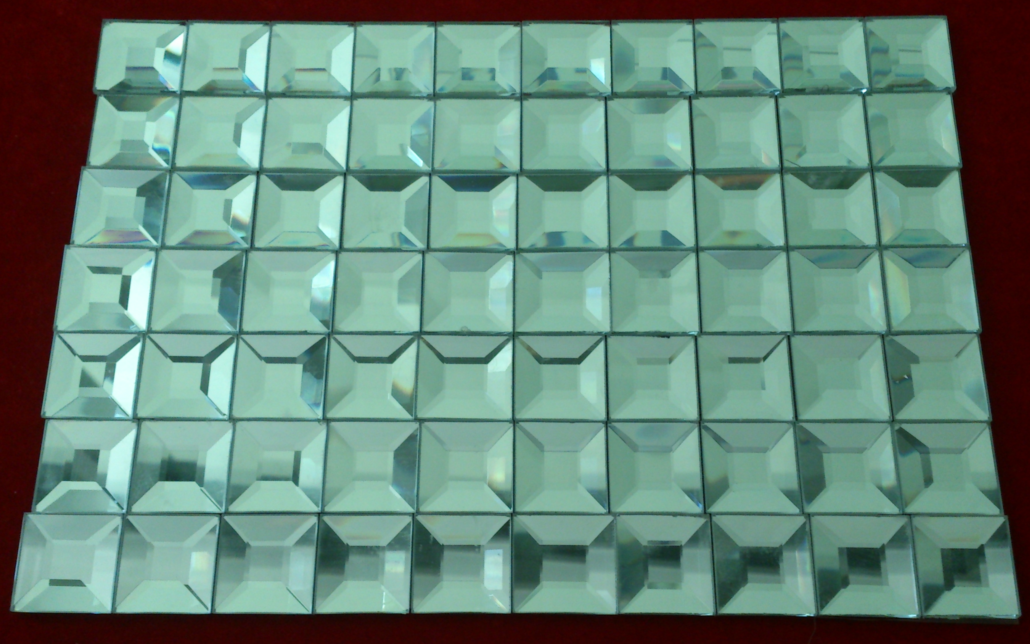

Handles glass pieces as small as 3030mm, enabling intricate work on delicate decorative items alongside larger panels.

3. Precision-Finish Glass Bevelling Machine Operation:

Advanced control systems and high-quality spindles produce flawless bevelled edges free of chips or imperfections, crucial for aesthetic-critical applications.

4. Automated-Throughput Glass Bevelling Machine Design:

Automation features minimize manual intervention, streamlining processes for higher throughput and reduced production costs.

5. Industrial-Duty Glass Bevelling Machine Construction:

Built with robust materials to withstand continuous operation, ensuring long-term reliability with reduced maintenance needs.

6. Intuitive Operational Interface:

User-friendly controls enable easy parameter setting and process monitoring, accessible to operators with minimal technical experience.

---

Product Applications

This Glass Straight-line Bevelling Machine serves critical sectors:

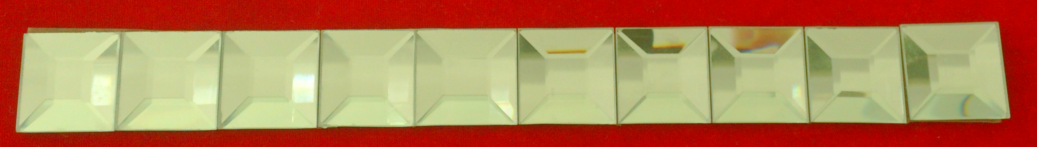

Mirror Production: Precision bevelling for residential/commercial mirrors requiring flawless edges

Decorative Glass Manufacturing: Processing intricate small items (≥30x30mm) and artistic pieces

Architectural Glass Elements: Bevelling structural components and facade elements

Glass Furniture Fabrication: Creating premium edges for tabletops, shelves, and fixtures

Industrial Glass Components: Handling diverse sizes and thicknesses for specialized applications

---

Product Advantages

1. Enhanced Processing Versatility:

As a 10-Spindle Glass Bevelling Machine, it accommodates glass from 30x30mm to large panels, adapting to diverse production demands without reconfiguration.

2. Premium Edge Quality:

The Precision-Finish Glass Bevelling Machine capability delivers consistently smooth, defect-free bevels critical for high-end mirrors and furniture.

3. High-Volume Efficiency:

Functioning as an Automated-Throughput Glass Bevelling Machine, it reduces labor requirements by 30-50% while increasing output for scalable production.

4. Industrial-Grade Reliability:

Industrial-Duty Glass Bevelling Machine construction ensures 24/7 operational readiness with <2% annual downtime, lowering lifetime maintenance costs by 40%.

5. Reduced Operational Complexity:

Intuitive controls shorten operator training by 60% and minimize setup errors, improving overall productivity.

6. Risk Mitigation:

Precision spindle alignment reduces glass breakage rates by ≥25%, decreasing material waste.

7. Cost Efficiency:

Combines higher throughput with lower labor/maintenance costs, achieving ROI within 14-18 months for most operations.

---

Conclusion

The DXM361 10-Spindle Glass Bevelling Machine redefines industrial glass processing through five core attributes: Its foundational capability as a Glass Straight-line Bevelling Machine ensures linear precision; the 10-Spindle configuration guarantees consistent quality; Precision-Finish technology delivers flawless aesthetics; Automated-Throughput design maximizes productivity; and Industrial-Duty construction ensures unwavering reliability. Serving mirror manufacturers, architectural glass fabricators, and decorative glass specialists, this machine excels in processing diverse sizes – from intricate 30x30mm components to large panels – while maintaining uncompromised quality. For facilities prioritizing throughput efficiency, operational cost control, and premium finish standards, the DXM361 establishes itself as an indispensable asset in competitive glass markets.

Wheel position with respect to the incoming sheet | ||||||||||

DXM261 | ||||||||||

Ref.no | No10 | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 |

Motor | 1.5Kw 1400rpm | 1.5Kw 1400rpm | 1.5Kw 1400rpm | 2.2Kw 2840rpm | 2.2Kw 2840rpm | 2.2Kw 2840rpm | 2.2Kw 2840rpm | 2.2Kw 2840rpm | 2.2Kw 2840rpm | 2.2Kw 2840rpm |

Name | Wool wheel | Wool wheel | Wool wheel | Resin wheel | Resin wheel | Resin wheel | Resin wheel | Rounding wheel | Diamond wheel | Diamond wheel |

Specification | 150×22 Wool | 150×22 Wool | 150×22 Wool | 150×22 10S40 | 150×22 500 mesh | 150×22 320 mesh | 150×22 240 mesh | 175×22 240 mesh | 150×22 180 mesh | 150×22 100 mesh |

Usage | Beveling polishing | Beveling polishing | Beveling polishing | Beveling fine grinding | Beveling fine grinding | Beveling fine grinding | Beveling fine grinding | Bottom Grinding | Beveling fine grinding | Beveling rough grinding |

Machine model | DXM 361 | ||

Processing (m/min) | 0.7~3.65 | ||

Min. processing glass size (mm) | 30*30 | ||

Glass thickness a | 3~19mm | ||

Remain thickness b | ≥1.5 | ||

Width Of bevel Bmax | 30mm | ||

Angle of bevel θ |

| 3°~25° |

|

Machine overall: L×B×H(mm) | 7250×1300×2500 | ||

Dimension for main machine L1×B1×H1(mm) | 4866×1225×1500 | ||

Base dimension L2×B2(mm) | 3160×650 | ||

Length of infeeding track L3 | 6980 | ||

Net weight of main machine(kg) | 4500 | ||

Total Power(kw) | 23.5 | ||