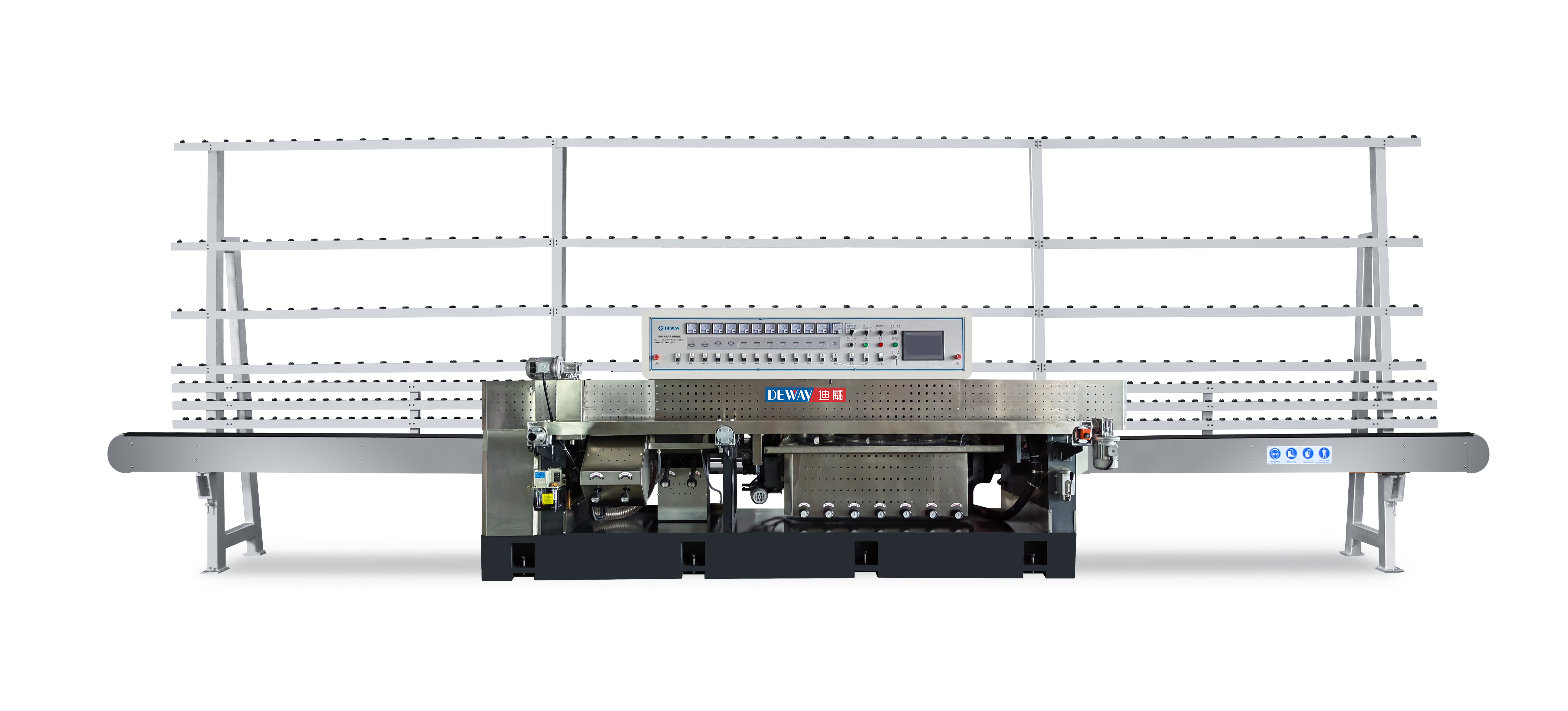

Product Introduction: DJM11 Glass Miter Machine (11 Spindles)

The DJM11 Glass Miter Machine (11 Spindles) is a cutting-edge solution designed for the glass processing industry, delivering unmatched precision and versatility. As a leading Glass Straight-line Variable Edging Machine, it excels in producing high-quality edges with complex angle capabilities. This machine is essential for manufacturers of architectural glass, mirrors, and decorative glass products requiring superior edge processing.

---

Product Features

1. Glass Straight-line Variable Edging Capability:

Functioning as a Glass Straight-line Variable Edging Machine, the DJM11 processes precise straight-line edges while accommodating complex angle requirements for diverse design applications.

2. Glass Flat Edging and Variable Angle Changing:

Designed as a Glass Flat edging and variable angle changing machine, it enables effortless switching between straight edges and angled cuts. This flexibility meets diverse demands across modern glass applications, from minimalist designs to intricate angular patterns.

3. Glass Miter Machine with 45-Degree Precision:

The DJM11 operates as a Glass Miter Machine with 45 degree, creating precise mitered edges essential for perfectly aligned glass corners and joints. Its 11 synchronized spindles ensure accurate, clean cuts for smooth polished edges.

4. Glass Angle Changing Polishing Function:

This Glass Angle Changing Polishing Machine provides seamless transitions between edge angles while delivering polished finishes. It maintains high-quality results for both simple straight edges and challenging 45-degree bevels.

5. Glass Flat Edging and Bevelling with 45-Degree Versatility:

The Glass Flat edging and bevelling with 45 degree capability allows simultaneous creation of flat edges and precise beveled edges on a single glass piece, streamlining production workflows.

6. Industrial-Grade Construction:

Built from high-quality materials to withstand continuous industrial use, ensuring long operational life with minimal downtime and maintenance.

7. Safety-Enhanced Operation:

Equipped with user-friendly controls, protective enclosures, and emergency stop functions for safe operation in high-volume environments.

---

Product Applications

The DJM11 Glass Straight-line Variable Edging Machine is essential for:

- Architectural Glass Fabrication: Processing structural elements requiring precise miters and polished edges.

- Mirror Manufacturing: Creating flawless edges and bevels for residential/commercial mirrors.

- Decorative Glass Products: Producing intricate angular patterns for artistic installations.

- Frameless Glass Systems: Constructing perfect 45-degree mitered joints using its Glass Miter Machine with 45 degree capability.

- Integrated Edge Solutions: Executing combined flat edging and beveling tasks via its Glass Flat edging and bevelling with 45 degree function for multi-profile glass components.

---

Product Advantages

1. Multi-Functional Precision:

As both a Glass Straight-line Variable Edging Machine and Glass Flat edging and variable angle changing machine, it eliminates equipment changes for straight/angled edge transitions, enhancing processing accuracy.

2. 45-Degree Mitering Excellence:

The Glass Miter Machine with 45 degree function guarantees perfectly aligned corners and joints critical for structural glass assemblies.

3. Seamless Finish Transitions:

Operating as a Glass Angle Changing Polishing Machine, it maintains consistent polished finishes across all angle adjustments (0-45 degrees), eliminating secondary polishing steps.

4. Production Streamlining:

The Glass Flat edging and bevelling with 45 degree capability allows single-machine processing of multi-profile edges, reducing handling time and equipment costs.

5. Industrial Durability:

Robust construction ensures reliable operation in continuous production environments, minimizing maintenance costs and maximizing ROI.

6. Operational Safety:

Integrated safety systems and intuitive controls protect operators while maintaining workflow efficiency during high-volume processing.

7. Enhanced Productivity:

11 synchronized spindles enable simultaneous multi-edge processing without compromising precision, ideal for custom and volume production.

---

Conclusion

The DJM11 Glass Miter Machine (11 Spindles) delivers industry-leading versatility through its integrated capabilities: As a Glass Straight-line Variable Edging Machine, it handles complex straight-edge processing; its Glass Flat edging and variable angle changing machine functionality enables seamless transitions between edge profiles; the Glass Miter Machine with 45 degree ensures precision corner joints; its Glass Angle Changing Polishing Machine feature maintains finish consistency across angles; and the Glass Flat edging and bevelling with 45 degree capability streamlines multi-profile production. Combining these functions with industrial durability and safety, the DJM11 provides an indispensable solution for architectural glass, mirrors, and decorative applications requiring uncompromised precision and efficiency in edge processing.

Wheel position with respect to the incoming sheet | |||||||||||

DJM11 | |||||||||||

Ref.no | No11 | No10 | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 |

Rev.(50Hz) | 2800 | 2800 | 2800 | 2800 | 1400 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 |

Rev.(60Hz) | 3360 | 3360 | 3360 | 3360 | 1680 | 3360 | 3360 | 3360 | 3360 | 3360 | 3360 |

| Power(kW) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

Name | Fine grinding wheel | Resin wheel | Fine grinding wheel | Resin wheel | Polishing wheel | Fine grinding wheel | Fine grinding wheel | Resin wheel | Resin wheel | Diamond wheel | Diamond wheel |

Specification | 10S40 150×70 | 150×22 240 mesh | 10S40 150×70 | 150×22 240 mesh | X098 150×70 | 10S60 150×70 | 10S40 150×70 | 150×22 240 mesh | 150×22 180 mesh | 150×22 180 mesh | 150×22 100 mesh |

Usage | Fine grinding for front arris | Semi fine grinding for front arris | Fine grinding for back arris | Semi fine grinding for back arris | Miter polishing | Fine grinding for Miter | Fine grinding for Miter | Semi fine grinding for Miter | Semi fine grinding for Miter | Miter rough grinding | Miter rough grinding |

Technical data

DJM11 | |

Max. Glass size | 2400×3600mm |

Min. Glass size | 40×40mm |

Glass thickness | 3-25mm |

Transmission speed | 0.5-7m/min |

Max. hemline grinding | 5mm |

Arris grinding range | 0.5-5mm |

Power | 27.5KW |

Weight | 6800kg |

| Land occupation | 7658×1450×2700mm |

glass diagonal error | ≤0.5mm/m |

glass parallelism error | ≤0.3mm/m |