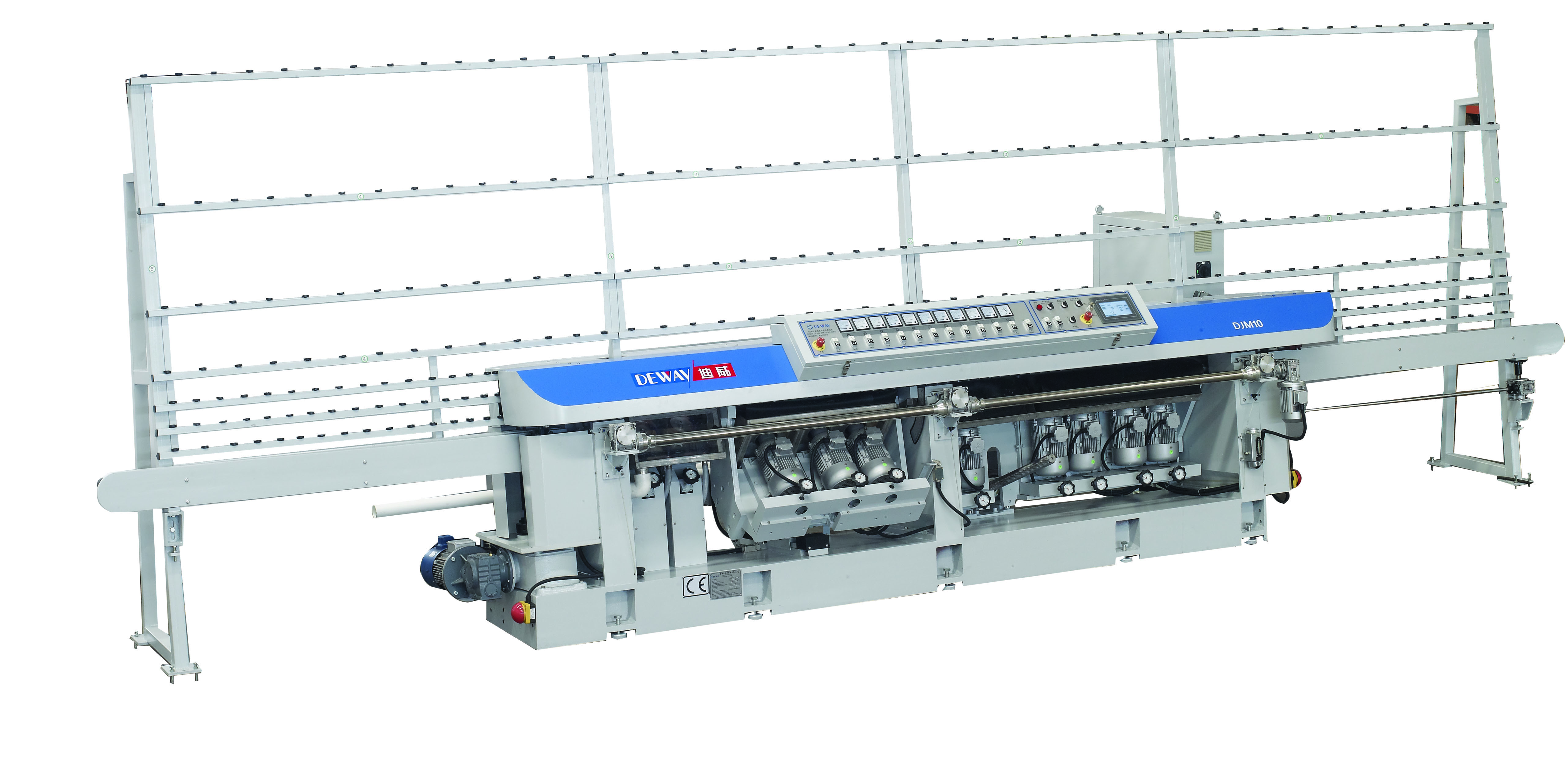

Product Introduction: DJM10B Glass Miter Machine With Bearing Conveyor (10 Spindles)

The DJM10B Glass Miter Machine is a cutting-edge Glass Straight-line Edge with Variable Miter Machine, engineered for precision glass edging and mitering. It delivers unparalleled accuracy and efficiency in processing glass edges, excelling in producing variable miters and straight-line edges with flawless precision. Equipped with 10 spindles, this machine is designed for demanding glass fabrication applications.

---

Product Features

1. Variable Miter Straight-line Edging:

As a Glass Straight-line Edge with Variable Miter Machine, the DJM10B enables seamless adjustments to the miter angle. Its advanced technology allows users to achieve desired angles with ease, supporting complex mitering requirements.

2. Ball Bearing Conveyor System:

This Glass Mitering Machine Ball Bearing features a specialized ball bearing conveyor. This system significantly reduces friction compared to traditional belt conveyors, ensuring smoother movement of glass sheets through the machine. The ball bearings securely hold the glass during operation, minimizing slippage or misalignment.

3. 45-Degree Mitering Capability:

Designed as a Glass bearing Mitering Machine with 45 degree, the DJM10B creates 45-degree miters with exceptional accuracy. It maintains consistent quality across varying glass thicknesses, essential for precision applications.

4. Angle Adjustment Functionality:

Operating as a Glass Angle Changing Edging Machine with 45 degree, it offers versatile angle changes, particularly crucial for achieving exact 45-degree edges.

5. Dedicated 45-Degree Performance:

The machine excels as a Glass Straight-line 45 degree mitering Machine, producing clean, smooth, and flawless 45-degree mitered edges through its robust spindle and conveyor systems.

6. Multi-Spindle Configuration:

The 10 meticulously calibrated spindles ensure uniform performance and consistent edge quality across all processing stages.

7. User Control Interface:

An intuitive control interface allows operators to set and adjust processing parameters rapidly, enhancing operational flexibility.

---

Product Applications

The DJM10B Glass Straight-line Edge with Variable Miter Machine is essential for applications demanding high-precision glass edge finishes:

- Architectural Glass Installations: Processing complex miters for structural and decorative glass elements.

- Frameless Glass Doors & Shower Enclosures: Creating precise 45-degree miters for seamless joints, utilizing its capability as a Glass Straight-line 45 degree mitering Machine.

- Glass Furniture Manufacturing: Edging and mitering glass components for tables, shelves, and decorative items.

- Custom Glass Projects: Handling specialized requirements for unique designs and installations where the Glass Angle Changing Edging Machine with 45 degree functionality is critical.

- Decorative Glass Installations: Producing accurately mitered edges for mirrors, partitions, and artistic panels.

---

Product Advantages

1. Superior Edge Precision:

The Glass Mitering Machine Ball Bearing conveyor system ensures flawless edge quality by minimizing glass slippage and misalignment during processing, critical for achieving perfect miters.

2. Enhanced Processing Efficiency:

Reduced friction from the ball bearing conveyor increases operational speed, while the 10-spindle design enables high throughput for both volume production and custom work.

3. Exceptional Versatility:

Functionality as both a Glass Straight-line Edge with Variable Miter Machine and a Glass bearing Mitering Machine with 45 degree allows handling diverse mitering tasks (0-45 degrees) and glass thicknesses within a single platform.

4. Reliable 45-Degree Output:

As a dedicated Glass Straight-line 45 degree mitering Machine, it guarantees consistently clean, smooth, and defect-free 45-degree mitered edges meeting the highest industry standards.

5. Operational Precision & Stability:

The Glass Angle Changing Edging Machine with 45 degree capability ensures accurate angle setting and maintenance throughout the edging process, reducing rework and material waste.

6. User-Centric Operation:

The intuitive interface facilitates quick setup and parameter adjustments, minimizing downtime and operator training requirements.

7. Robust Construction:

Engineered for durability and long-term reliability in demanding industrial glass processing environments.

---

Conclusion

The DJM10B Glass Miter Machine With Bearing Conveyor (10 spindles) represents the pinnacle of glass edging and mitering technology. Its core identity as a Glass Straight-line Edge with Variable Miter Machine is enhanced by critical features: the friction-reducing Glass Mitering Machine Ball Bearing conveyor, its precision as a Glass bearing Mitering Machine with 45 degree, the flexibility of a Glass Angle Changing Edging Machine with 45 degree, and its specialized performance as a Glass Straight-line 45 degree mitering Machine. This combination delivers unmatched precision, reliability, and efficiency, making the DJM10B an indispensable asset for producing high-quality mitered and straight-line edges in architectural projects, furniture, shower enclosures, and custom glass fabrication.

| Wheel position with respect to the incoming sheet | ||||||||||

| DJM10 | ||||||||||

| Ref.no | No10 | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 |

| Rev.(50Hz) | 2800 | 2800 | 2800 | 2800 | 1400 | 2800 | 2800 | 2800 | 2800 | 2800 |

| Rev.(60Hz) | 3360 | 3360 | 3360 | 3360 | 1680 | 3360 | 3360 | 3360 | 3360 | 3360 |

| Name | Fine grinding wheel | Resin wheel | Fine grinding wheel | Resin wheel | Felt wheel | Fine grinding wheel | Fine grinding wheel | Resin wheel | Diamond wheel | Diamond wheel |

| Specification | 130×50 10S40 | 130×50 240 mesh | 130×50 10S40 | 130×50 240 mesh | 150 | 10S60 150×70 | 10S40 150×70 | 150×50 240 mesh | 150×50 180 mesh | 150×50 100 mesh |

| Usage | Fine grinding for back arris | Semi fine grinding for back arris | Fine grinding for front arris | Semi fine grinding for front arris | Bottom polishing | Bottom polishing | Bottom polishing | Bottom fine grinding | Semi fine grinding for bottom | Bottom rough grinding |

Technical data

DJM10 | |

Length [mm] | 7500 |

Width [mm] | 1900 |

Height [mm] | 2500 |

Work top height [mm] | 900±30 |

Total weight [kg] | 3600 |

Workable thickness [mm] | 3~25 |

Beveling angle | 0°~45° |

Minimum glass size [mm]: | 120x120 |

Maximum working weight: | 300 |

per meter of transport [kg / m] | 100 |

Total [kg] | 300 |

Conveyor speed [m / min] | 1~6 |

Tanks: | 1+1(Optional) |

water [no x l] | 1*165 |

cerium oxide [no x l] (Optional) | 1*75 (Optional) |

Rated voltage [V] | 380V/50Hz(can be optional) |

Installed power [kW] | 21.8 |