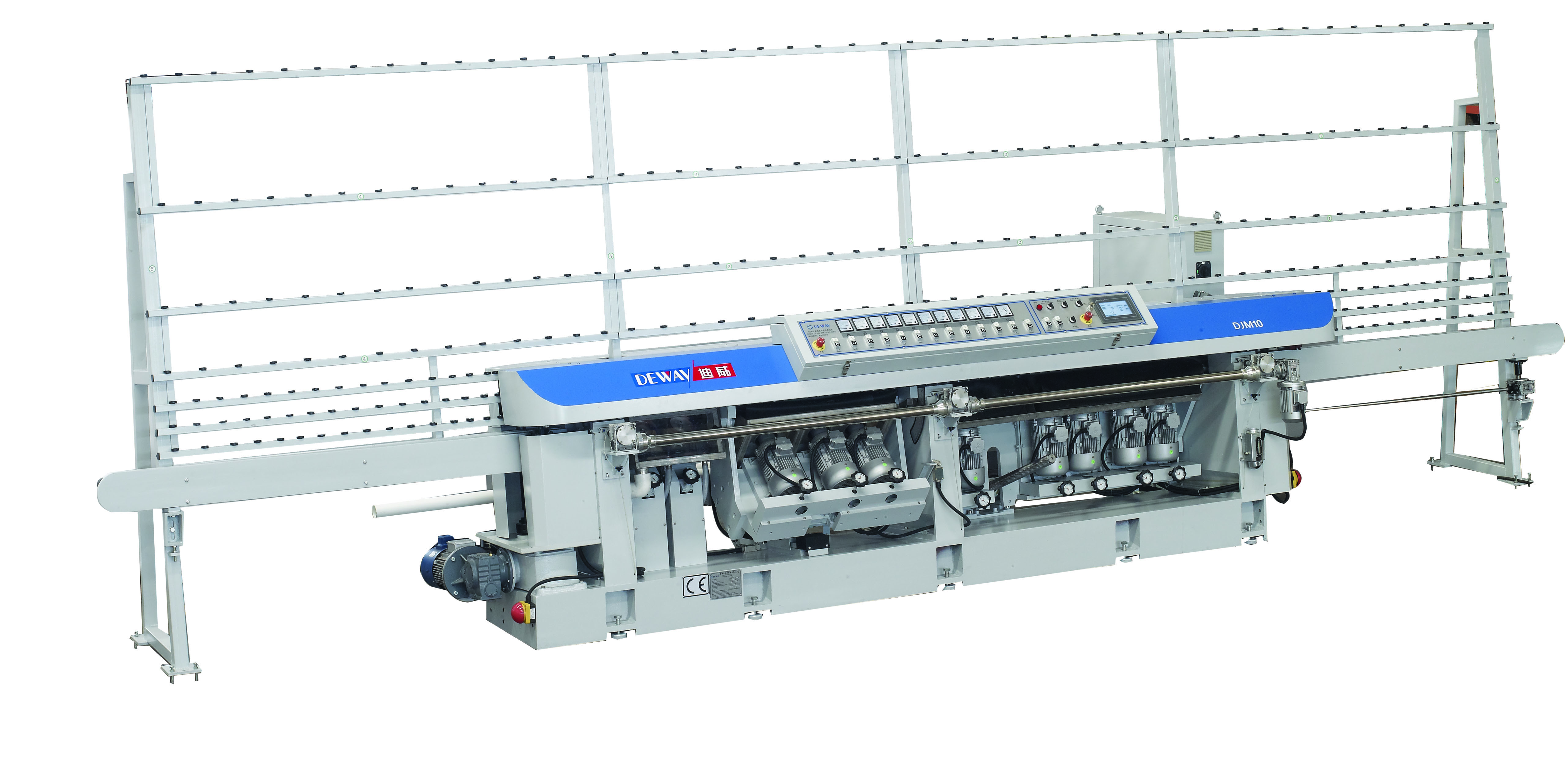

Product Introduction

The DJM10 Mitering Edging Machine represents cutting-edge technology in precision glass processing. Engineered as a specialized Glass Mitering Edging Machine, it delivers unparalleled 45° mitered edges for premium applications. This versatile system functions simultaneously as a Glass Variable Mitering Machine for custom angles, a Glass Mitering Polishing Machine for integrated finishing, a Glass Angle Changing Machine for on-the-fly adjustments, and a precision Glass Straight-line 45 Degree Edger - making it indispensable for modern glass fabrication.

---

Product Features

1. Precision Mitering System

- Glass Mitering Edging Machine capability delivers consistent 45° edges (±0.1° tolerance)

- Diamond grinding wheels ensure geometrically perfect edges for frameless installations

2. Variable Angle Technology

- Glass Variable Mitering Machine function accommodates 30°-60° angles

- Digital angle control enables acute/obtuse adjustments without mechanical recalibration

3. Integrated Polishing Mechanism

- Glass Mitering Polishing Machine system with cerium polishing heads

- Single-pass transition from cutting to high-gloss finishing (Ra 0.3μm)

4. Dynamic Angle Adjustment

- Glass Angle Changing Machine feature allows real-time angle modification during operation

- Memory presets store 12+ angle configurations for batch production

5. Straight-Line Precision

- Glass Straight-line 45 Degree Edger functionality maintains ±0.15mm linear accuracy

- Laser-guided alignment ensures geometric consistency for partitions and doors

---

Product Applications

1. Architectural Glazing

- Precision mitering for frameless glass doors via Glass Straight-line 45 Degree Edger

2. Premium Furniture Manufacturing

- 45° bevel edges on display cases using Glass Mitering Edging Machine

3. Custom Architectural Features

- Non-standard angle processing (e.g., 52°) with Glass Variable Mitering Machine

4. Luxury Retail Displays

- Seamless polished miters for museum cases through Glass Mitering Polishing Machine

5. Complex Structural Glass

- On-site angle adjustments for curved installations via Glass Angle Changing Machine

---

Product Advantages

1.Precision Engineering Excellence

- The Glass Mitering Edging Machine achieves <0.1mm edge consistency across 10,000+ cycles - critical for structural glazing. Digital angle verification ensures ±0.05° angular accuracy.

2.Operational Versatility

- Functioning as both Glass Variable Mitering Machine (30°-60° range) and Glass Straight-line 45 Degree Edger, it eliminates need for multiple machines. Quick-change tooling transitions between functions in 90 seconds.

3.Integrated Finishing Quality

- As a Glass Mitering Polishing Machine, it delivers mirror finishes in single processing pass. Cerium polishing heads reduce secondary operations by 70% while achieving EN 12150-1 compliant surfaces.

4.Production Flexibility

- The Glass Angle Changing Machine capability allows real-time design modifications without stopping production. Memory presets accelerate batch changeovers by 80%.

5.Geometric Perfection

- Precision-ground linear guides in Glass Straight-line 45 Degree Edger mode maintain ±0.15mm straightness over 3m lengths - essential for seamless glass joints.

6.Economic Efficiency

- 55% faster processing versus conventional mitering systems. Energy-recovery braking reduces power consumption by 30% during continuous operation.

7.Quality Assurance

- Automated pressure control in Glass Mitering Polishing Machine mode prevents edge overheating. Vibration-dampened spindles ensure <0.5μm surface variation.

Wheel position with respect to the incoming sheet | ||||||||||

DJM10 | ||||||||||

Ref.no | No10 | No9 | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 |

Rev.(50Hz) | 2800 | 2800 | 2800 | 2800 | 1400 | 2800 | 2800 | 2800 | 2800 | 2800 |

Rev.(60Hz) | 3360 | 3360 | 3360 | 3360 | 1680 | 3360 | 3360 | 3360 | 3360 | 3360 |

Name | Fine grinding wheel | Resin wheel | Fine grinding wheel | Resin wheel | Felt wheel | Fine grinding wheel | Fine grinding wheel | Resin wheel | Diamond wheel | Diamond wheel |

Specification | 130×50 10S40 | 130×50 240 mesh | 130×50 10S40 | 130×50 240 mesh | 150 | 10S60 150×70 | 10S40 150×70 | 150×50 240 mesh | 150×50 180 mesh | 150×50 100 mesh |

Usage | Fine grinding for back arris | Semi fine grinding for back arris | Fine grinding for front arris | Semi fine grinding for front arris | Bottom polishing | Bottom polishing | Bottom polishing | Bottom fine grinding | Semi fine grinding for bottom | Bottom rough grinding |

Technical data

DJM10 | |

Length [mm] | 7500 |

Width [mm] | 1900 |

Height [mm] | 2500 |

Work top height [mm] | 900±30 |

Total weight [kg] | 3600 |

Workable thickness [mm] | 3~25 |

Beveling angle | 0°~45° |

Minimum glass size [mm]: | 120x120 |

Maximum working weight: | 300 |

per meter of transport [kg / m] | 100 |

Total [kg] | 300 |

Conveyor speed [m / min] | 1~6 |

Tanks: | 1+1(Optional) |

water [no x l] | 1*165 |

cerium oxide [no x l] (Optional) | 1*75 (Optional) |

Rated voltage [V] | 380V/50Hz(can be optional) |

Installed power [kW] | 21.8 |