Glass machinery refers to specialized equipment used in the production and processing of various types of glass. Primarily categorized into cold processing and hot processing equipment, this machinery is essential for the modern glass industry. Cold processing equipment, including glass edging machines, washing machines, and sandblasters, handles surface treatment, while hot processing equipment, such as tempering furnaces and heat bending furnaces, alters the internal structure of the glass.

Main Categories of Glass Machinery

The array of glass machinery is extensive, encompassing float glass production lines, grid method production lines, tempering furnaces, heat soak ovens, laminated glass lines, insulating glass lines, coating lines, screen printing equipment, glass edging machines, glass washing machines, fully automatic sandblasting machines, polishing machines, loading tables, cutting machines, drilling machines, and engraving machines. Among these, glass washing machines and edging machines are the most commonly used.

Key Equipment Highlights

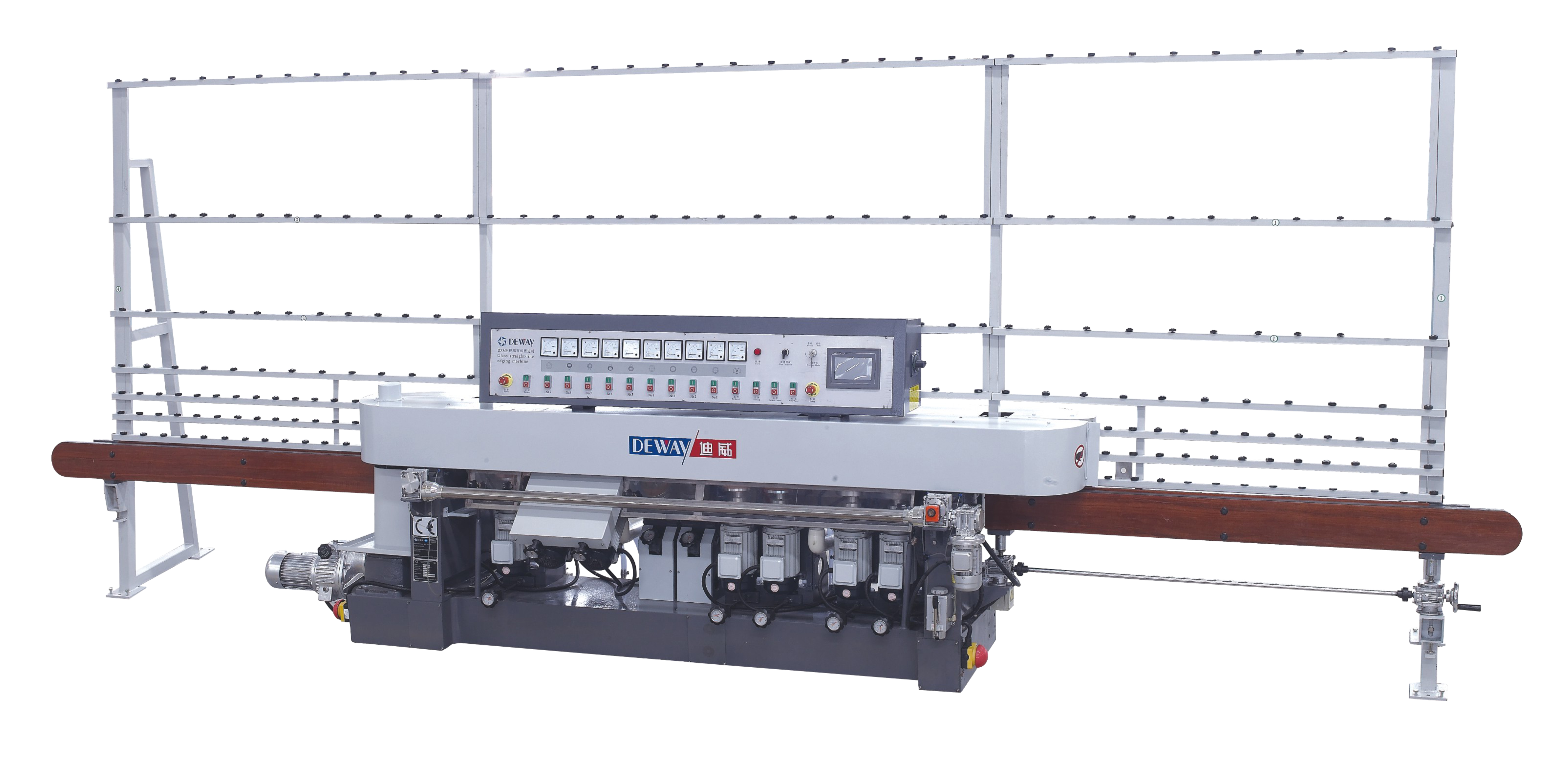

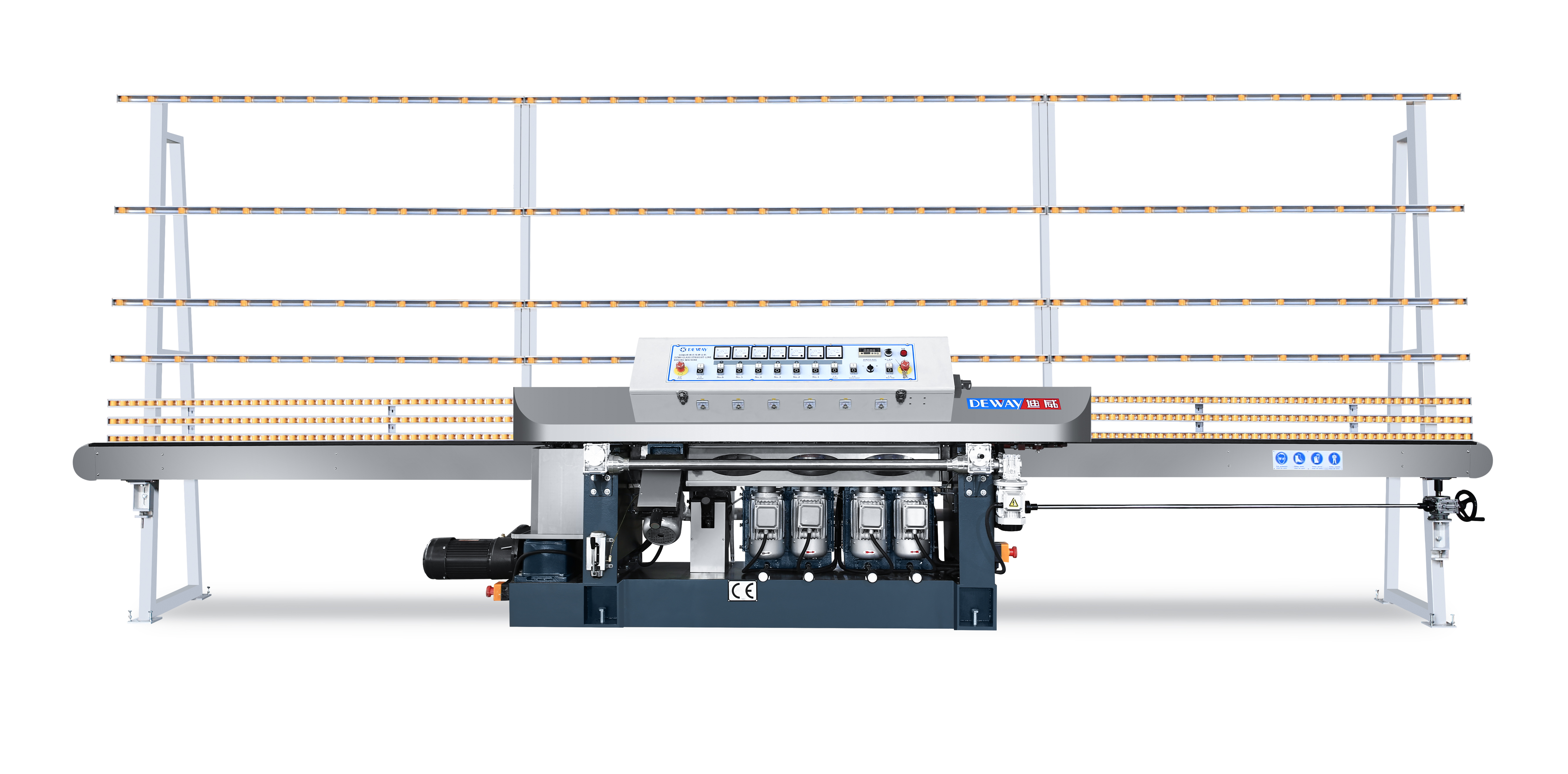

· Glass Edging Machine

One of the earliest and most widely used cold processing machines, it is suitable for processing furniture, architectural, and decorative glass. Its primary function is grinding and polishing the edges and corners of flat glass. Configurations range from manual to CNC and PLC computer-controlled systems. The quality of the raw glass, operational techniques, and equipment condition are key factors affecting surface scratches during grinding.

· Glass Washing Machine:

This is specialized equipment for cleaning and drying glass surfaces before further processing like mirroring, vacuum coating, tempering, heat bending, or insulating glass assembly. A standard machine comprises a transmission system, brushing, rinsing with water and pure water, and cold/hot air drying sections. Larger models often include manual or pneumatic turnover carts and inspection light systems.

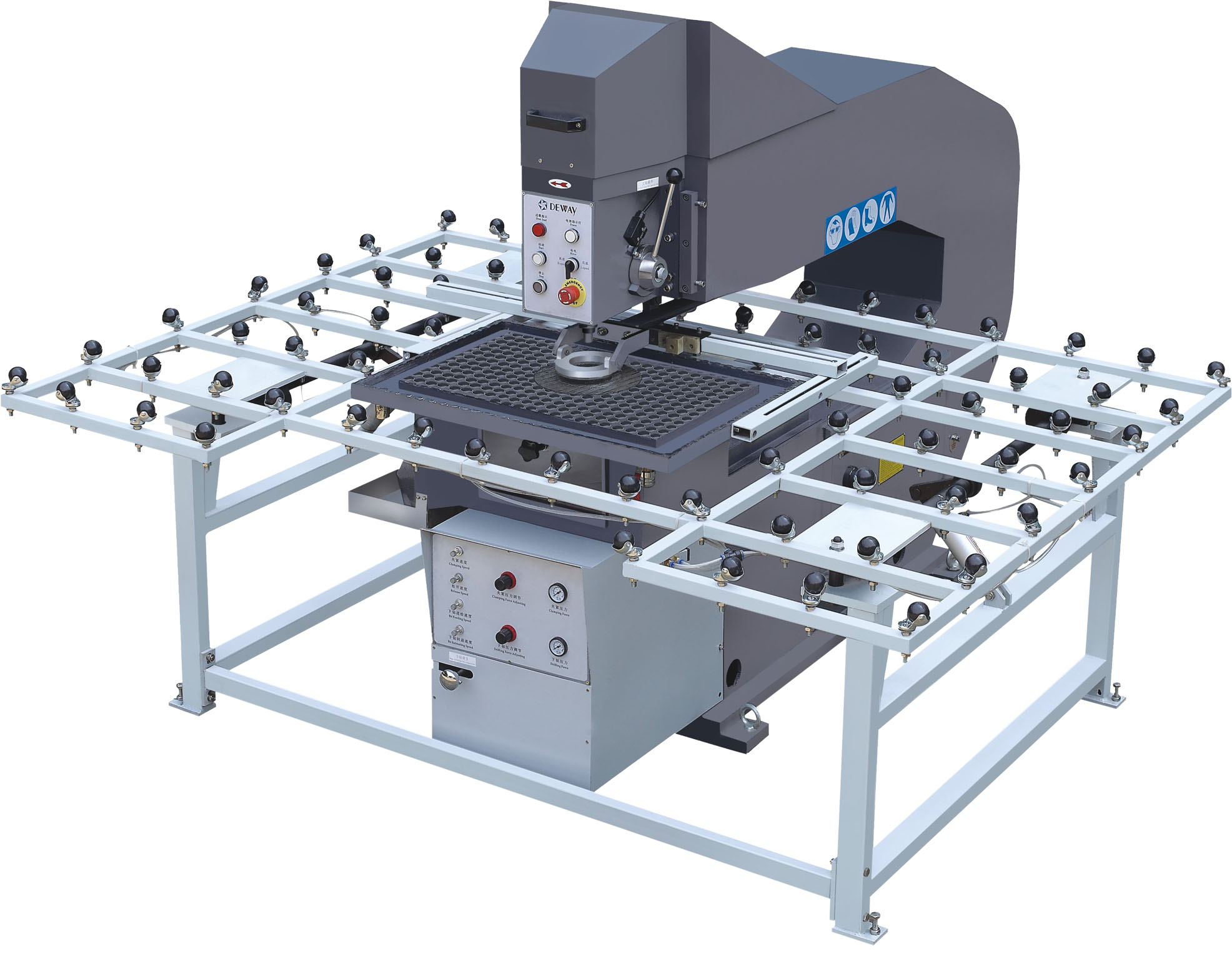

· Glass Drilling Machine:

Designed specifically for drilling holes in glass, this machine features a base, worktable, drill bit, and motor. It is characterized by a large drilling diameter capacity, significant overhang space for handling various glass sizes, and a low worktable for easy operation. The lower drill head often uses pneumatic speed control for consistent performance.

Industry Development and Current Status

China's glass machinery industry began its development in the early 1990s, initially fueled by the relocation of foreign-invested (primarily Taiwanese) enterprises. As global manufacturing shifted and China's domestic industry rapidly expanded, the glass processing machinery sector grew significantly. Early pioneers, like Shenzhen Ywega Industrial Development Co., soon led to the formation of clusters in the Pearl River Delta and Yangtze River Delta regions.

By the early 2000s, the industry's growth began to follow the establishment of glass processing factories. Major industrial clusters emerged in Foshan, Shenzhen, Guangzhou, Shanghai, Hangzhou, Suzhou, and Zhangjiagang. This expansion continued into the Shandong Peninsula and the Bohai Rim region, spreading further to inland cities. Notably, over 50% of China's cold processing equipment is manufactured in Shunde, Guangdong.

As of 2014, the industry's development remained highly dependent on the international market. However, the promising outlook for the glass processing sector itself indicates sustained growth potential for machinery manufacturers. From 2011 to 2013, the demand for automotive and architectural laminated safety glass in China was projected to grow at an annual rate of approximately 30%.

Future Trends

Glass, as a fundamental material for construction, automotive, and consumer goods, is playing an increasingly diverse role. This presents both opportunities and challenges for machinery producers. By 2014, flexible manufacturing processes and multi-functional equipment were recognized as global trends. The industry demands machinery with high repeatability and precision. The ongoing effort in automotive and architectural sectors to use thinner glass places greater demands on deep processing technology. Consequently, many processors are focusing on enhancing production line efficiency and integrating various aspects of the deep processing chain, signaling the direction for the industry's future evolution.