PRODUCT INTRODUCTION

The DZJ13 Glass Drilling Machine (1 Pair Driller) is a cutting-edge Glass Drilling equipment engineered for modern glass manufacturing demands. Designed for precision and efficiency, this Glass Driller delivers reliable performance for both large-scale industrial production and specialized custom projects, establishing itself as an essential tool in glass processing.

PRODUCT FEATURES

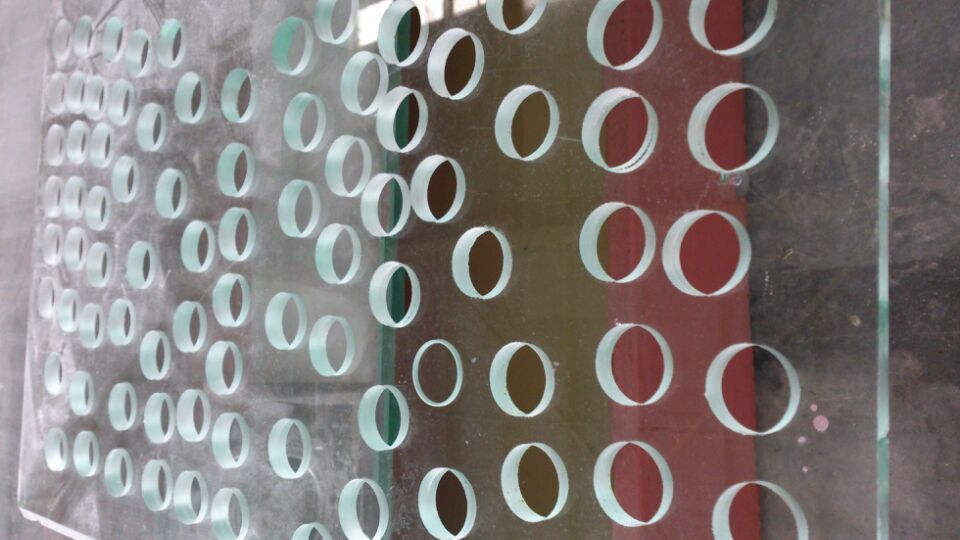

1. Synchronized Dual-Head Drilling

As a specialized Glass double heads drilling machine, it features paired drilling heads operating simultaneously from both glass surfaces. This ensures perfect hole alignment, eliminating micro-cracks and imperfections while enabling precision hole placement.

2. Fully Automated Operation

Functioning as an Automatic glass drilling machine, its advanced control system simplifies parameter setting (hole diameter/depth/position). Automation ensures consistent results across production batches while reducing manual labor.

3. Industrial-Grade Construction

Built with high-quality materials and high-torque motors, this Glass Drilling equipment withstands continuous operation and drills through all glass types (including toughened/laminated variants) without performance degradation.

4. Integrated Safety Systems

Includes automatic glass clamping for positional stability during drilling and dust extraction systems to maintain workspace cleanliness and operator safety.

PRODUCT APPLICATIONS

Precision Component Fabrication:

Ideal for architectural glass (balustrades, facades), automotive glass (sunroofs, sensor mounts), and decorative glass requiring micron-level hole accuracy.

Specialized Material Processing:

Handles standard float glass and specialized materials (toughened, laminated, coated) for custom industrial or artistic projects.

PRODUCT ADVANTAGES

1. Unmatched Hole Alignment Accuracy

The Glass double heads drilling machine technology eliminates bilateral misalignment, ensuring burr-free holes with perpendicularity tolerance <0.1°.

2. Production Efficiency Optimization

Automation reduces drilling cycle times by ≈40% versus manual operations while maintaining consistent quality across high-volume runs.

3. Reduced Operational Complexity

User-friendly controls on this Automatic glass drilling machine minimize training requirements and prevent setup errors.

4. Enhanced Processing Safety

Integrated clamping and dust management systems prevent glass shifting and airborne particulate hazards.

5. Material Versatility & Tool Longevity

Processes 3-25mm thick glass substrates without tool changes. Robust construction extends service intervals by 30% versus standard drillers.

SUMMARY

The DZJ13 Glass Drilling Machine redefines precision drilling through its synchronized Glass double heads drilling machine architecture. Combining the reliability of industrial Glass Drilling equipment with the efficiency of an Automatic glass drilling machine, it delivers flawless hole quality for architectural, automotive, and decorative applications. This Glass Driller sets new benchmarks for accuracy and productivity in glass fabrication.

Technical parameter

Diameter for the glass hole | φ5~φ110 ㎜ |

Glass thickness range | 3~20mm |

Maxi processing size glass size | 2700mm X 2200mm |

Table height | 920mm |

Hole at drilling axis and drilling bit connection end | taper k=60°, screw hole G1/2” |

Distance between drilling center and back column | 1340 mm |

Main body size | 2200mmX1050mmX1600mm |

Overall size | 2500mmX2200mmX1600mm |

Weight | 1100KG(about) |

Total power | 3.45KW |