PRODUCT INTRODUCTION

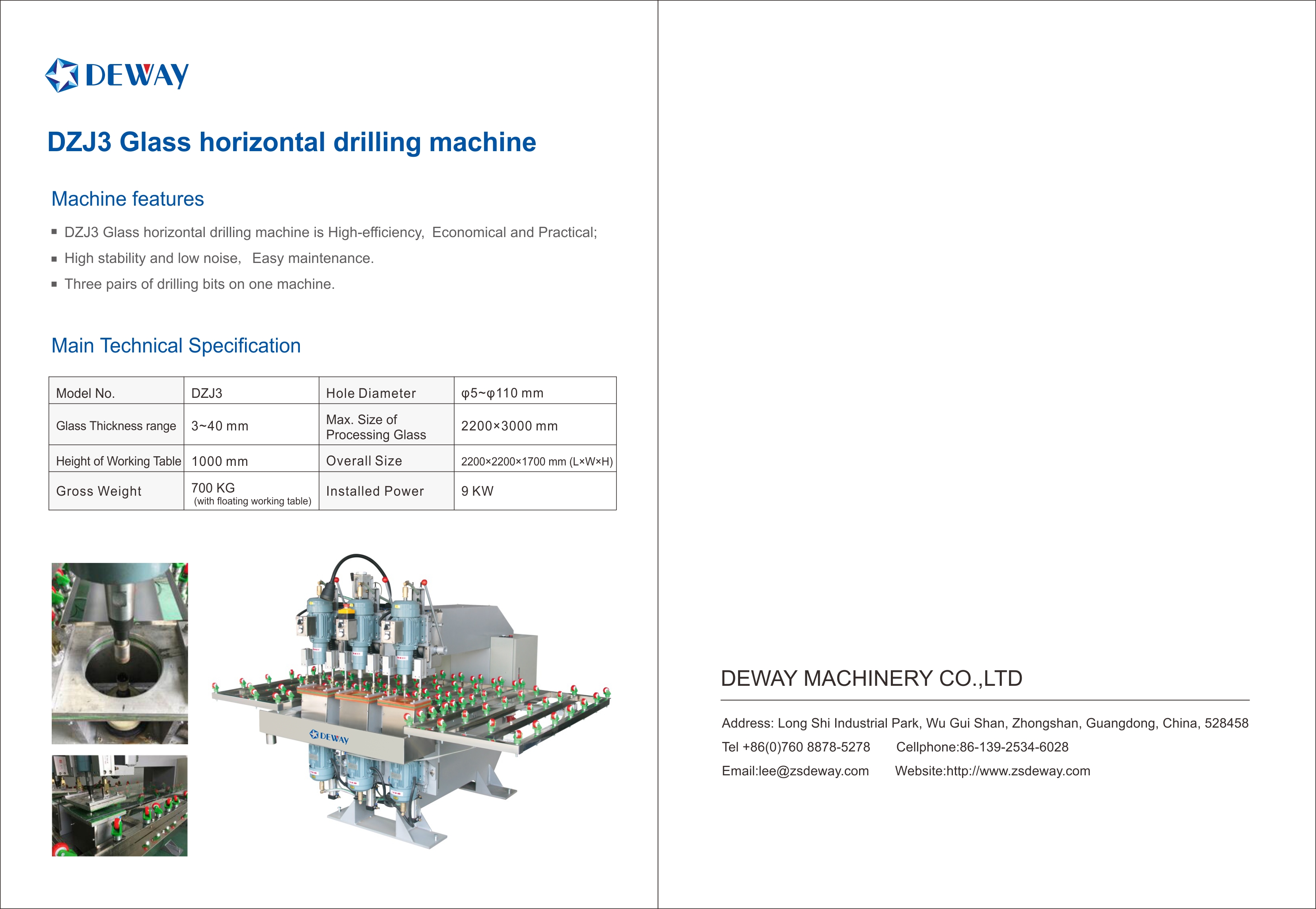

The DZJ3 Drilling Machine for glass (3 Pairs Driller) represents a state-of-the-art sol. engineered to meet rigorous glass drilling demands. This advanced Drilling glass machine delivers precision, efficiency & versatility in glass processing applications.

PRODUCT FEATURES

1. Advanced Triple-Head Drilling Tech.

As specialized Glass Drilling Hole equipment, it incorporates 3 pairs of precision drills operating in perfect synchronization. This 3 heads Glass drilling configuration ensures accurate hole placement with minimal deviation, producing clean holes in intricate glass components.

2. Material & Thickness Versatility

Adapts seamlessly to diverse glass types (tempered, laminated, etc.) and variable thickness/size parameters. The triple-drill system enables simultaneous multi-hole processing, significantly enhancing throughput efficiency for both small-scale and large-scale production.

3. Operator-Optimized Interface

Features intuitive controls with programmable settings and automated functions, streamlining operation for users of all experience levels while reducing processing errors.

4. Precision Engineering

Robust construction with meticulous alignment/calibration systems maintains drilling accuracy throughout operational lifespan, ensuring consistent hole quality and dimensional compliance.

5. Integrated Safety Mechanisms

Equipped with protective covers, emergency stop functions, and breakage-minimizing design to ensure operator safety during drilling operations.

PRODUCT APPLICATIONS

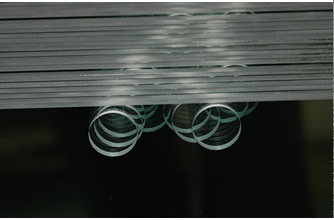

Multi-Surface Hole Processing:

Functions as Both side Glass drilling equipment for creating precision holes in architectural panels, automotive glass, and interior design elements across industries.

Specialized Component Fabrication:

Excels in producing fittings, fixtures, and decorative glass elements requiring exact hole placement in diverse glass substrates.

PRODUCT ADVANTAGES

1. Unmatched Hole Accuracy

Triple-drill synchronization guarantees uniform hole geometry and positioning accuracy critical for industrial standards.

2. Enhanced Production Efficiency

Simultaneous 3 heads Glass drilling capability reduces processing time by ≈67% versus single-head machines, optimizing output volumes.

3. Broad Material Compatibility

Processes all commercial glass variants (including tempered/laminated) with thickness adaptability, eliminating need for dedicated machinery.

4. Reduced Operational Complexity

User-friendly automation minimizes training requirements and prevents costly drilling errors during production runs.

5. Engineered Longevity & Safety

Precision components ensure extended service life while integrated safeguards protect personnel and materials during high-speed drilling.

SUMMARY

The DZJ3 Drilling Machine for glass redefines efficiency in glass fabrication through its 3 heads Glass drilling architecture. Combining the reliability of industrial-grade Glass Drilling Hole equipment with the flexibility of Both side Glass drilling equipment, it delivers precision-drilled components for construction, automotive, and design sectors. This Drilling glass machine sets the benchmark for productivity and accuracy in modern glass workshops.

Technical parameter

Hole diameter | φ5~φ110 ㎜ |

Thickness of processing glass | 3~40mm |

Max. size of processing glass | 2200×3000mm |

Height of working table | 1000mm |

Size | 2200×2200×1700mm (L×W×H) |

Weight | 900KG (with floating working table) |

Power | 6.8KW |