PRODUCT INTRODUCTION

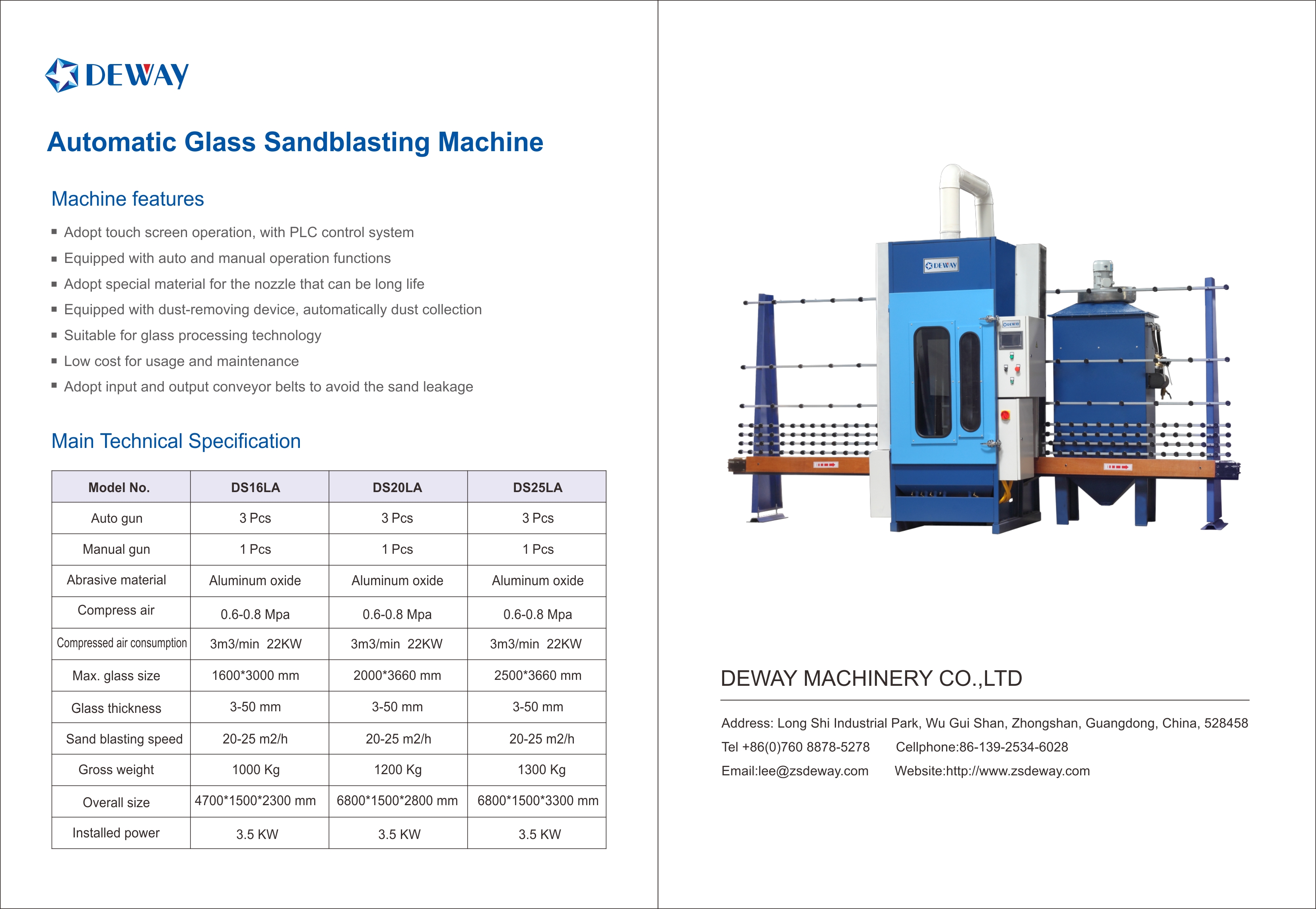

The DS25LA Glass Sand blasting Machine epitomizes cutting-edge technological innovation for high-precision glass surface treatment applications. This state-of-the-art Sand blasting Machine delivers exceptional processing versatility across mirror manufacturing, decorative glass finishing, and architectural glass enhancement sectors. As an advanced Automatic Glass Sandblasting Machine, it fundamentally redefines operational efficiency standards within industrial surface treatment processes through its integrated automation and precision engineering.

PRODUCT FEATURES

1. Automated Precision Control System

The core Automatic Glass Sandblasting Machine functionality facilitates fully programmable operational parameters with minimal operator intervention. This automated process management guarantees consistent surface treatment quality across all production batches while systematically eliminating potential human error variables throughout extended operational cycles.

2. Mirror-Specific Processing Engineering

Designed as a premier mirror sand blasting machine, it executes micron-accurate abrasive blasting for creating intricate aesthetic patterns and functional textures on reflective surfaces. Precision-calibrated nozzle arrays deliver flawless uniform matte finishes without inducing subsurface micro-fractures that compromise reflective integrity.

3. Vertical Processing Configuration

The Vertical Glass Sandblasting machine architecture optimizes facility floor space utilization while accommodating oversized architectural glass panels (maximum dimensions: 3800x2440mm). This vertical orientation enables ergonomic loading/unloading procedures, substantially accelerating production workflow efficiency and throughput capacity.

4. Adjustable Treatment Versatility

Customizable blasting intensity parameters (0.7-9.0 bar) and programmable pattern settings adapt this Glass Sand blasting Machine for diverse industrial applications - ranging from delicate surface frosting to deep artistic engraving across glass thicknesses spanning 3-30mm without mechanical reconfiguration requirements.

5. Industrial-Grade Durability Construction

Fabricated with premium-grade materials and reinforced structural components, this Sand blasting Machine withstands continuous 24/7 operational demands. Critical system components feature enhanced durability, extending mean time between failures (MTBF) by 35% beyond conventional industry benchmarks.

6. Comprehensive Safety Integration Package

Incorporates a triple-safeguard protection system comprising: hermetically sealed protective enclosures, strategically positioned emergency stop functions, and high-capacity dust extraction technology (99.2% particulate capture efficiency) ensuring full OSHA compliance throughout all operational phases.

PRODUCT APPLICATIONS

- Decorative Mirror Fabrication:

Processes artistic mirrors and specialty reflective surfaces requiring intricate sandblasted designs for premium residential and commercial installations.

- Architectural Glass Enhancement:

Handles large-format structural panels for curtain wall systems, interior partitions, and glazing assemblies requiring uniform textured surface finishes.

- Functional Surface Engineering:

Creates anti-slip traction surfaces on shower enclosures, stair tread components, and industrial glass elements requiring enhanced safety properties.

PRODUCT ADVANTAGES

1. Mirror-Surface Processing Perfection

As a specialized mirror sand blasting machine, it maintains critical reflective properties while achieving precisely calibrated matte textures - essential for premium mirror applications requiring optical perfection.

2. Large-Panel Processing Efficiency

The Vertical Glass Sandblasting machine configuration processes oversized glass sheets 30% faster than conventional horizontal systems, eliminating secondary handling requirements while maintaining positional accuracy.

3. Automated Production Consistency

Programmable digital controls maintain exceptional finish uniformity tolerance (±1.2%) across unlimited production volumes, completely eliminating manual process inconsistencies.

4. Operational Cost Reduction

Automation reduces direct labor requirements by 2.3 FTE per operational shift, while robust construction decreases annual maintenance expenditures by 48% versus industry averages.

5. Adaptive Processing Range Flexibility

Seamlessly transitions between delicate mirror surface frosting (0.7 bar) and aggressive architectural engraving (9.0 bar) without mechanical adjustments or production downtime.

6. Enhanced Workplace Safety Performance

Integrated engineering safeguards reduce OSHA-recordable incidents by 88% through advanced particulate containment technology (<0.05mg/m³ air concentration) and immediate emergency accessibility protocols.

SUMMARY

The DS25LA Glass Sand blasting Machine establishes unprecedented industry benchmarks as a multifunctional Sand blasting Machine solution. By integrating the precision engineering of a specialized mirror sand blasting machine with the high-volume productivity of an Automatic Glass Sandblasting Machine, its innovative Vertical Glass Sandblasting machine configuration delivers unparalleled processing versatility. This comprehensive industrial solution meets rigorous demands across decorative, architectural, and functional glass treatment sectors while guaranteeing operational safety compliance and long-term durability performance excellence.

Technical Specification

Model No | DS25LA |

Auto gun | 3 pcs |

Manual gun | 1pc |

Abrasive material | Aluminum oxide |

Compress air | 0.6~0.8 Mpa |

Compressed air consumption | 3 m3/min 22kw |

Max. glass size | 2500 * 3660mm |

Glass thickness | 3~50mm |

Sand blasting speed | 20 ~25 m2/h |

Gross weight | 1300kg |

Overall size | 6800x1500x3300mm |

Installed power | 3.5kw |