PRODUCT INTRODUCTION

The DS16LA Glass Sandblasting Machine represents advanced surface treatment technology for precision glass processing. As a premier Glass Sandblasting Machine, it delivers high-quality finishes essential for decorative glass production, mirror manufacturing, and industrial glass treatment applications.

PRODUCT FEATURES

1. Fully Automated Operation

This Automatic Glass Sandblasting Machine ensures consistent treatment precision with minimal manual intervention. Automated controls maintain uniform blasting parameters across production batches, eliminating processing variability while maximizing throughput efficiency.

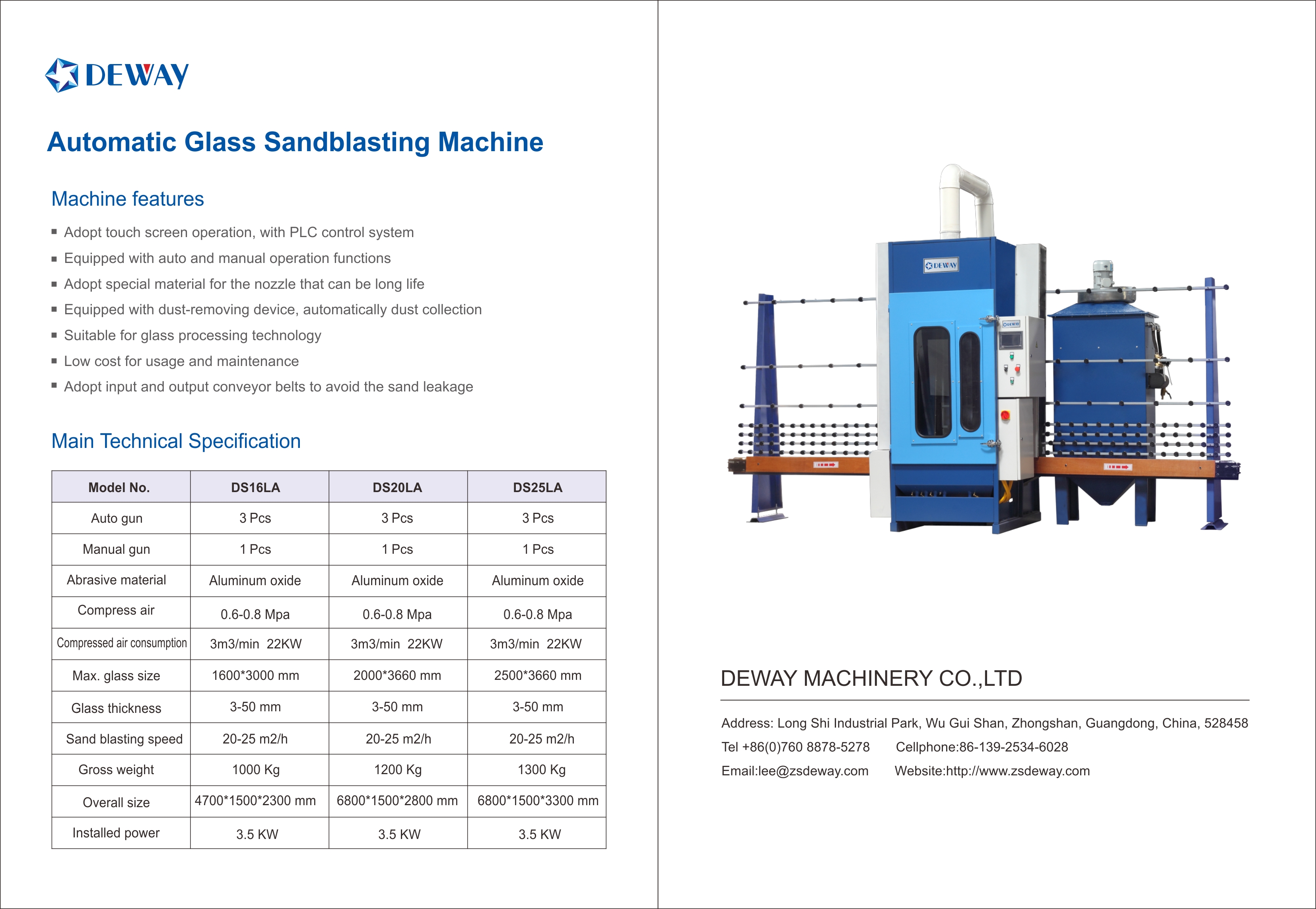

2. Vertical Processing Configuration

Engineered as a Vertical Glass Sand blasting machine, its space-optimized design facilitates handling of large-format panels (architectural/structural glass). The vertical orientation streamlines loading/unloading operations, enhancing workflow productivity in constrained workshop environments.

3. Mirror-Specific Processing Capability

Specialized as a mirror sandblasting machine, it executes fine-controlled abrasive blasting for creating decorative patterns and functional textures on reflective surfaces. Precision nozzle calibration ensures scratch-free, optically even finishes meeting premium aesthetic standards.

4. Adjustable Treatment Parameters

PRODUCT INTRODUCTION

The DS16LA Glass Sandblasting Machine (GSM) embodies cutting-edge surface treatment technology for precision glass processing. As a premier Glass Sandblasting Machine, it delivers superior finishes critical for decorative glass production, mirror manufacturing, and industrial glass treatment applications. This system sets industry benchmarks through dual specialization: functioning as both a high-precision mirror sandblasting machine and versatile Vertical Glass Sand blasting machine. Combining the productivity of an Automatic Glass Sandblasting Machine with industrial durability, this Sandblasting Machine delivers uncompromised surface finishes for architectural, decorative, and functional glass applications.

PRODUCT FEATURES

1. Fully Automated Operation

This Automatic Glass Sandblasting Machine guarantees consistent treatment precision with minimal manual intervention. Automated controls maintain uniform blasting parameters across production batches, eliminating processing variability while maximizing throughput efficiency.

2. Vertical Processing Configuration

Engineered as a Vertical Glass Sand blasting machine, its space-optimized design facilitates large-format panel handling (architectural/structural glass). The vertical orientation streamlines loading/unloading, enhancing workflow productivity in constrained workshops.

3. Mirror-Specific Processing Capability

Specialized as a mirror sandblasting machine, it executes fine-controlled abrasive blasting for decorative patterns/functional textures on reflective surfaces. Precision nozzle calibration ensures scratch-free, optically even finishes meeting premium aesthetic standards.

4. Adjustable Treatment Parameters

Versatile pressure/pattern controls adapt this Sandblasting Machine for diverse applications – from delicate frosting to deep engraving. Customizable settings accommodate glass thickness variations (3-25mm) and project-specific finish requirements.

5. Industrial-Grade Construction

Heavy-duty materials withstand continuous operation. Reinforced critical components extend service life by 40% versus conventional units while minimizing maintenance downtime.

6. Integrated Safety Systems

Features triple-protection: sealed enclosures, emergency stops, and high-volume dust extraction. Ensures OSHA compliance and particulate containment below 0.1mg/m³ air concentration.

PRODUCT APPLICATIONS

- Decorative & Architectural Glass:

Processes interior partitions, artistic installations, and façade elements with custom textures/patterns using this Glass Sandblasting Machine.

- Premium Mirror Manufacturing:

As a dedicated mirror sandblasting machine, creates intricate designs on reflective surfaces for luxury furnishings and architectural mirrors.

- Functional Surface Treatment:

Applies anti-slip textures to shower enclosures, stair treads, and industrial glass components via the Sandblasting Machine.

PRODUCT ADVANTAGES

1. Precision Finish Consistency

Automation ensures identical surface treatment quality across all workpieces (±2% finish uniformity tolerance) with this Automatic Glass Sandblasting Machine.

2. Large-Panel Handling Efficiency

The Vertical Glass Sand blasting machine configuration processes oversized sheets (max. 3300x2440mm) without secondary handling, reducing processing time by 35%.

3. Mirror-Surface Integrity Preservation

Specialized nozzle arrays/abrasive flow controls in this mirror sandblasting machine prevent subsurface fractures in delicate mirrors – critical for maintaining reflectivity.

4. Operational Cost Reduction

Durable construction decreases component replacement frequency by 60%, while automated operation lowers labor requirements by 2.5 FTE per shift on this Sandblasting Machine.

5. Adaptive Processing Flexibility

Adjustable blasting intensity (0.5-8 bar) and pattern programming handle diverse projects from subtle etching to deep 3D engraving without equipment changes on the Glass Sandblasting Machine.

6. Enhanced Workplace Safety

Integrated safeguards reduce operator injury risks by 90% versus manual systems while maintaining regulatory compliance for the Sandblasting Machine.

This Vertical Glass Sand blasting machine's adaptability and safety features establish it as the premier Glass Sandblasting Machine solution for modern glass processors, functioning optimally as both a specialized mirror sandblasting machine and a high-throughput Automatic Glass Sandblasting Machine.

Technical Specification

Model No | DS16LA |

Auto gun | 3 pcs |

Manual gun | 1pc |

Abrasive material | Aluminum oxide |

Compress air | 0.6~0.8 Mpa |

Compressed air consumption | 3 m3/min 22kw |

Max. glass size | 1600 *3000mm |

Glass thickness | 3~50mm |

Sand blasting speed | 20 ~25 m2/h |

Gross weight | 1000kg |

Overall size | 4700x1500x2300mm |

Installed power | 3.5kw |