Glass edging machines stand as one of the earliest and most widely used pieces of equipment in the glass deep-processing sector. Their primary functions include polishing glass edges and creating specific shapes for architectural and decorative glass applications.

Versatile Machine Types for Diverse Needs

The market offers several key types of edging machines, each designed for specific processing requirements.

The Glass Shape Edging/Bevelling Machine, often called a single-arm or shape edger, is renowned for its versatility and cost-effectiveness. It handles straight, round, pencil, and beveled edges on workpieces ranging from circles and ovals to irregular shapes using templates, making it a fundamental tool for many workshops.

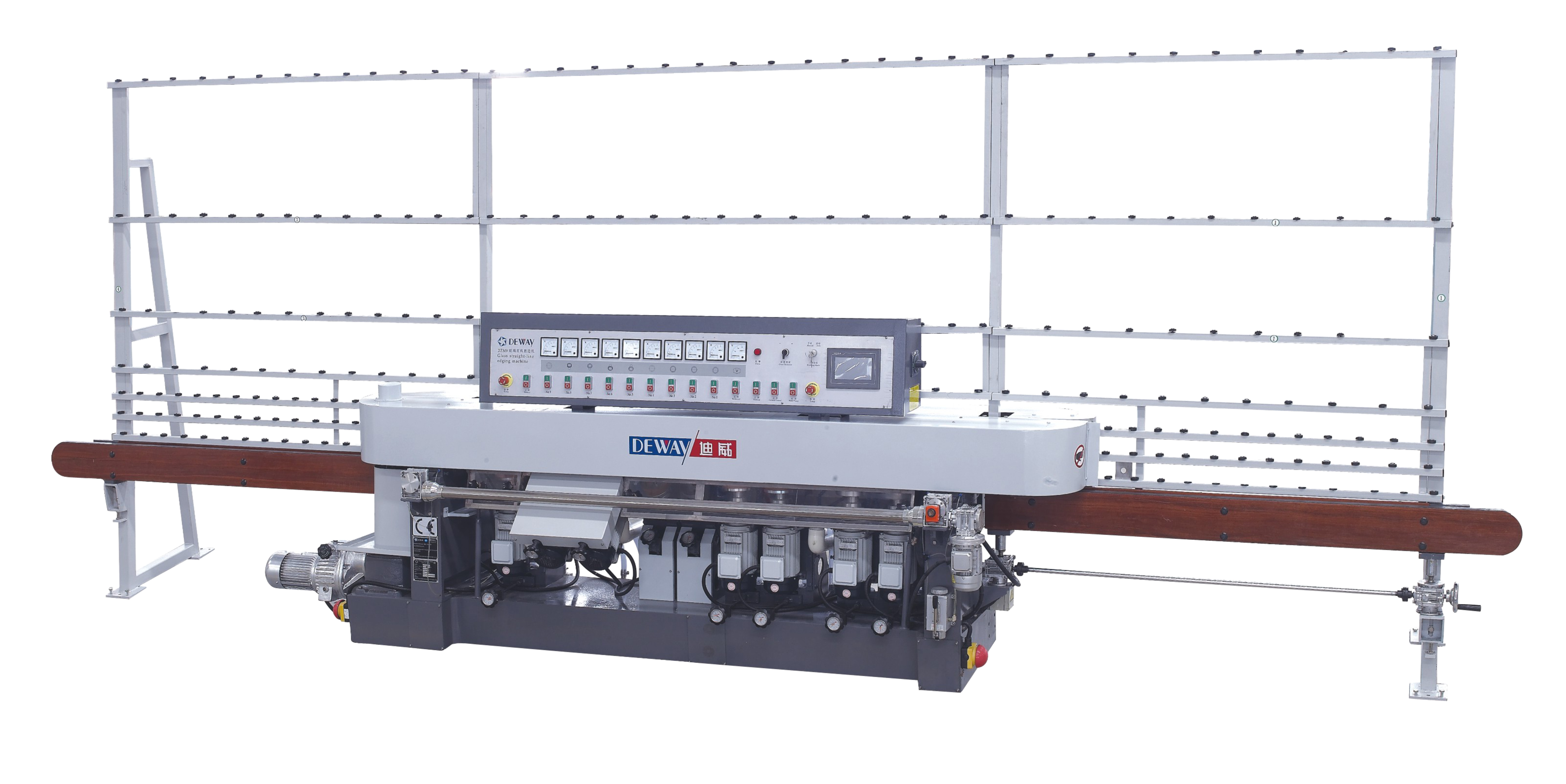

For high-volume straight-edge processing, the Glass Straight-line Edging Machine is the go-to solution. It ensures continuous, efficient grinding and is capable of handling large glass sheets. This category further branches into subtypes: the basic straight-line edger for flat and chamfered edges; the Glass Straight-line Pencil Edging Machine specialized for round and pencil edges popular in furniture and decor; and the bevel edger for angles typically between 3 and 45 degrees, including newer models that create wavy patterns.

The Automated Glass Beveling Machine, or template / copying machine, excels in precision and consistency. Using custom templates, it accurately grinds straight, round, or beveled edges on circular or shaped glass, making it ideal for large batches of a limited product range.

Representing the pinnacle of automation, the CNC Working Center is designed for processing 3-8mm glass of virtually any shape. It integrates multiple steps—edging, chamfering, and polishing—into a single, automated, and highly efficient process, ensuring superior safety and finish quality.

Key Considerations for Optimal Operation

Proper operation is crucial for maintaining quality and machine longevity. Key guidelines include thoroughly reading manuals before use, maintaining adequate cooling systems to prevent clogging, and carefully adjusting grinding head positions.

For shape edgers, ensuring vacuum pump efficiency and level suction cups is vital. Operators of straight-line models must maintain lubrication on guide rails and calibrate clamping pressure carefully—too loose compromises quality, too tight risks breakage. Template machine performance heavily relies on precise, smooth templates. High-end models like bilateral edgers or CNC centers require dedicated operators and professional servicing for complex adjustments. A universal rule is to only adjust variable speed drives while the machine is running to prevent damage.

The evolution from versatile single-arm machines to fully automated CNC Working Centers reflects the glass industry's growing demand for precision, efficiency, and complex design capability, solidifying these machines' indispensable role in modern glass fabrication.