The glass machinery sector in China is poised for significant evolution in 2025, driven by technological innovation, sustainability mandates, and shifting market dynamics. Industry experts forecast several key trends that will reshape the competitive landscape, with advanced equipment such as the automatic glass processing machine and glass edging machine playing pivotal roles.

Intelligent and Automated Manufacturing Takes Center Stage

The industry is rapidly advancing toward high-end, intelligent production. Companies are increasing R&D investments in automated lines and smart control systems, including automatic glass detection machines to ensure precision and quality, meeting growing demand for high-efficiency equipment. Notably, the adoption rate of intelligent machinery in glass deep-processing is projected to exceed 40%, with integrated systems like double edging line machines becoming standard in modern factories.

Green Transition Fuels Technological Advancements

Stringent environmental policies are accelerating the shift toward energy-saving and emission-reduction solutions. Innovations include optimizing fuel structures—such as adopting natural gas—and enhancing resource efficiency, with waste glass recovery rates targeted to reach 90%. Low-consumption equipment, such as energy-efficient furnaces, is becoming mainstream, supported by automation that minimizes waste through tools like automatic glass detection machines.

Vertical Integration Strengthens Supply Chain Resilience

In response to volatile raw material costs, leading firms are moving upstream by securing critical resources and expanding overseas production. Strategies include investing in key mineral sources and establishing manufacturing bases in Southeast Asia to mitigate supply risks, making integrated supply chain coordination a vital competitive edge for producing core machinery like glass edging machines and glass grooving machines.

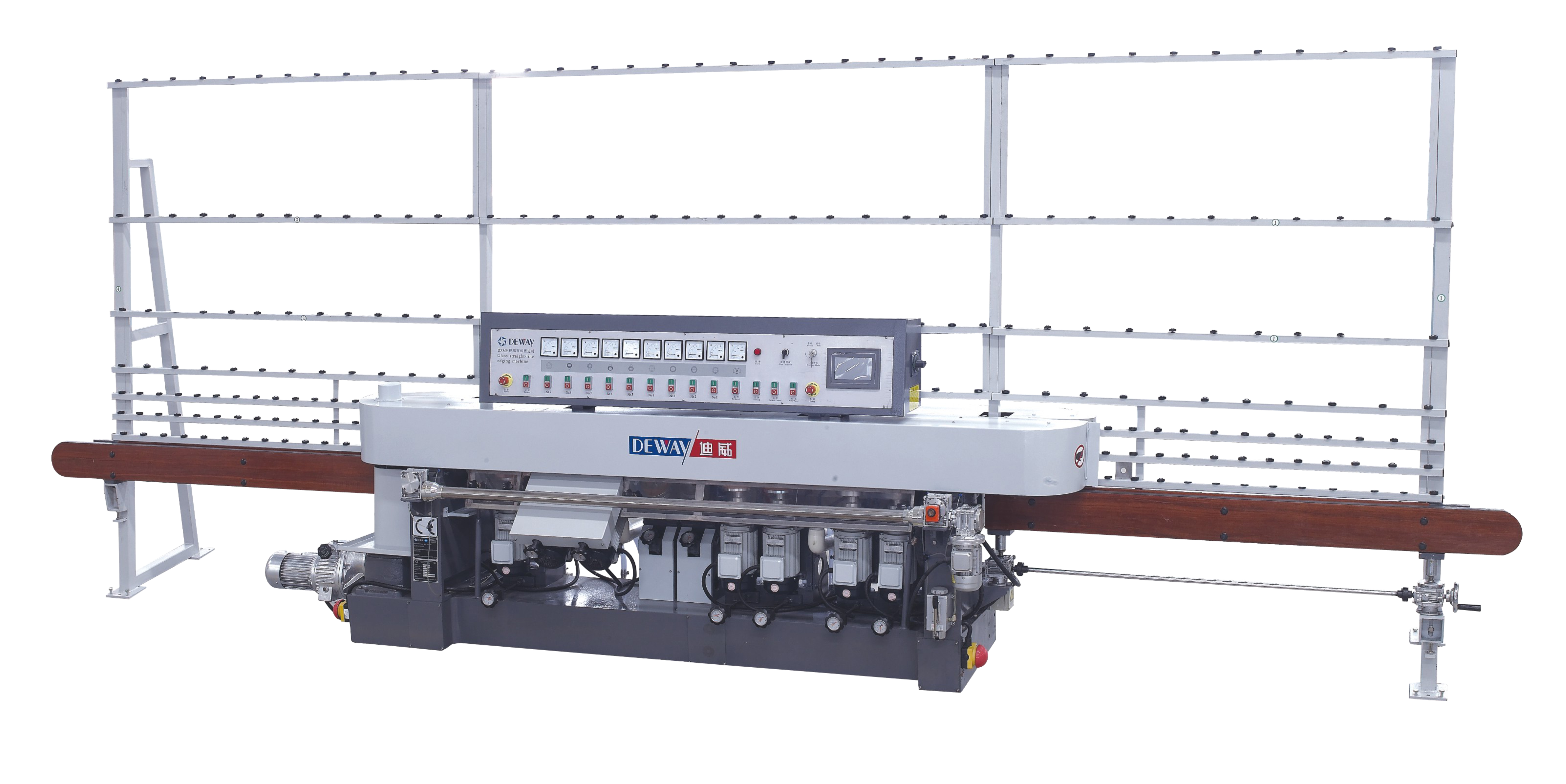

Niche Advanced Markets Drive Demand Growth

Emerging applications in sectors like new energy vehicles and smart homes are boosting demand for functional glass, thereby expanding the market for precision processing machinery. Equipment such as glass grooving machines, double edging line machines, and other automatic glass processing machines are seeing rising orders. Specifically, devices for ultra-thin glass and electronic glass processing, including advanced glass edging machines, are anticipated to see demand growth of 15–20%.

Policy and Market Forces Boost Industry Consolidation

Government initiatives, including the national Glass Industry Development Plan, emphasize technological upgrades. This pressure is accelerating the exit of smaller players, while giants such as Xinyi and Fuyao are set to capture greater market share with their scale and technological advantages in producing high-end equipment like automatic glass detection machines and glass grooving machines. The combined market share of the top five enterprises is expected to surpass 60%.

Global Expansion Accelerates

Chinese manufacturers are accelerating their international footprint through technology exports and overseas acquisitions, particularly in emerging markets like Southeast Asia and the Middle East. The industry’s export proportion is forecast to rise from 25% in 2024 to around 35%, with key products including automatic glass processing machines and double edging line machines driving overseas sales.

Together, these trends highlight an industry in the midst of a strategic upgrade, positioning itself for more sustainable, efficient, and globally competitive growth, underpinned by advanced machinery across the value chain.