PRODUCT INTRODUCTION

The DYM1 Glass Shape Edging/Bevelling Machine is a versatile precision tool engineered for intricate processing of irregularly shaped glass. Combining manual control with advanced technology, this Irregular Shape Edging/beveling machine delivers high-quality finishes for manufacturers and artisans handling diverse glass shapes and sizes.

PRODUCT FEATURES

1. Advanced Shape Processing Capability

As a specialized Glass Shape Edging Machine, it masters both simple geometries (round/oval) and complex custom designs. Robust construction ensures consistent production of smooth edges and clean bevels across all shape profiles.

2. Irregular Shape Expertise

The core Irregular Shape Edging/beveling machine functionality handles intricate curves, angles, and contours through precision manual adjustments. Operators can achieve diverse edge profiles - from straight edges to elaborate OG configurations.

3. Manual Craftsmanship Control

Unique manual glass OG edging capability provides artisans with granular control over the edging process. This is essential for delicate/high-value pieces requiring customized finishing.

4. Integrated Beveling System

Functioning as a Glass Shape Bevelling Machine, it creates decorative/functional bevels on irregular shapes. Precision control systems ensure consistent bevel geometry meeting exact specifications.

PRODUCT APPLICATIONS

Decorative Glass Production:

Processes artistic glassware, decorative panels, and specialty products requiring intricate edge profiles on non-rectilinear shapes.

Custom Glass Furniture:

Finishes tabletops, shelves, and structural elements with precision bevels/edges for bespoke furniture pieces.

Architectural Glass Fabrication:

Handles specialty installations (mirrors, partition systems) demanding flawless edge finishing on custom-shaped glass.

PRODUCT ADVANTAGES

1. Unmatched Shape Versatility

This Glass Shape Edging/Bevelling Machine processes any contour - from basic geometries to highly irregular forms - without compromising finish quality.

2. Precision Craftsmanship Enablement

manual glass OG edging functionality grants artisans complete control for achieving millimeter-perfect edge profiles on unique pieces.

3. Dual-Function Efficiency

Combines Glass Shape Edging Machine and Glass Shape Bevelling Machine capabilities in one unit, eliminating need for separate equipment.

4. Premium Finish Consistency

Delivers optically smooth edges and precisely angled bevels meeting highest industry standards across all shape complexities.

5. Customization Flexibility

Manual adjustment features enable infinite edge profile variations for bespoke projects across decorative, architectural, and furniture applications.

SUMMARY

The DYM1 Glass Shape Edging/Bevelling Machine redefines irregular glass processing through its specialized Irregular Shape Edging/beveling machine engineering. By integrating the precision of a Glass Shape Edging Machine with the versatility of a Glass Shape Bevelling Machine - including critical manual glass OG edging control - it delivers uncompromised finishes for decorative glassware, custom furniture, and architectural installations. This solution sets the benchmark for craftsmanship in shaped glass fabrication.

Working Condition

Power | AC 3~ 380V±10% ,50Hz ±2% |

Ambient air temperature | 1℃~40℃ |

Air relative humidity | <=90% |

Applied vacuum degree scope | -0.08~-0.1Mpa |

Water Pressure | 0.1~0.2Mpa |

Air supply Pressure | 0.6~0.8Mpa |

Technical parameter

Grinding wheel diameter | Φ150mm. (for beveling and edging) |

Thickness of processed glass | 3~40mm |

Dimension of processed glass | Φ100mm~Φ2100mm |

Angle of bevel | 0~450 |

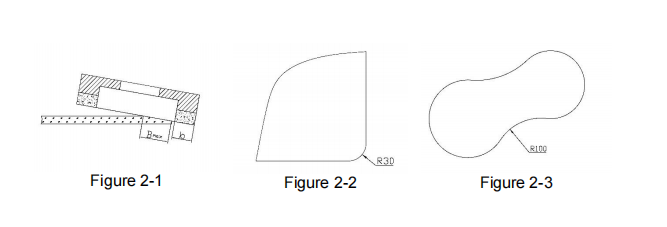

Maximum width of bevel | B max: 35mm(grinding wheel working width :b≤25mm. See figure: 2-1) |

Minimum curvature radius of outside circle upon continuous grinding | R30mm.(figure 2-2) |

Minimum curvature radius of inside circle | R100mm. (figure 2-3) |

Installation Powder | 3.0 KW. |

Total height of the main machine | 1640mm

|

Max. rotating radius | 1585mm |

Base Dimension | 1000mmx1000mm |

Height of working table | 1060mm |

Weight | about 800kg |