Product Introduction

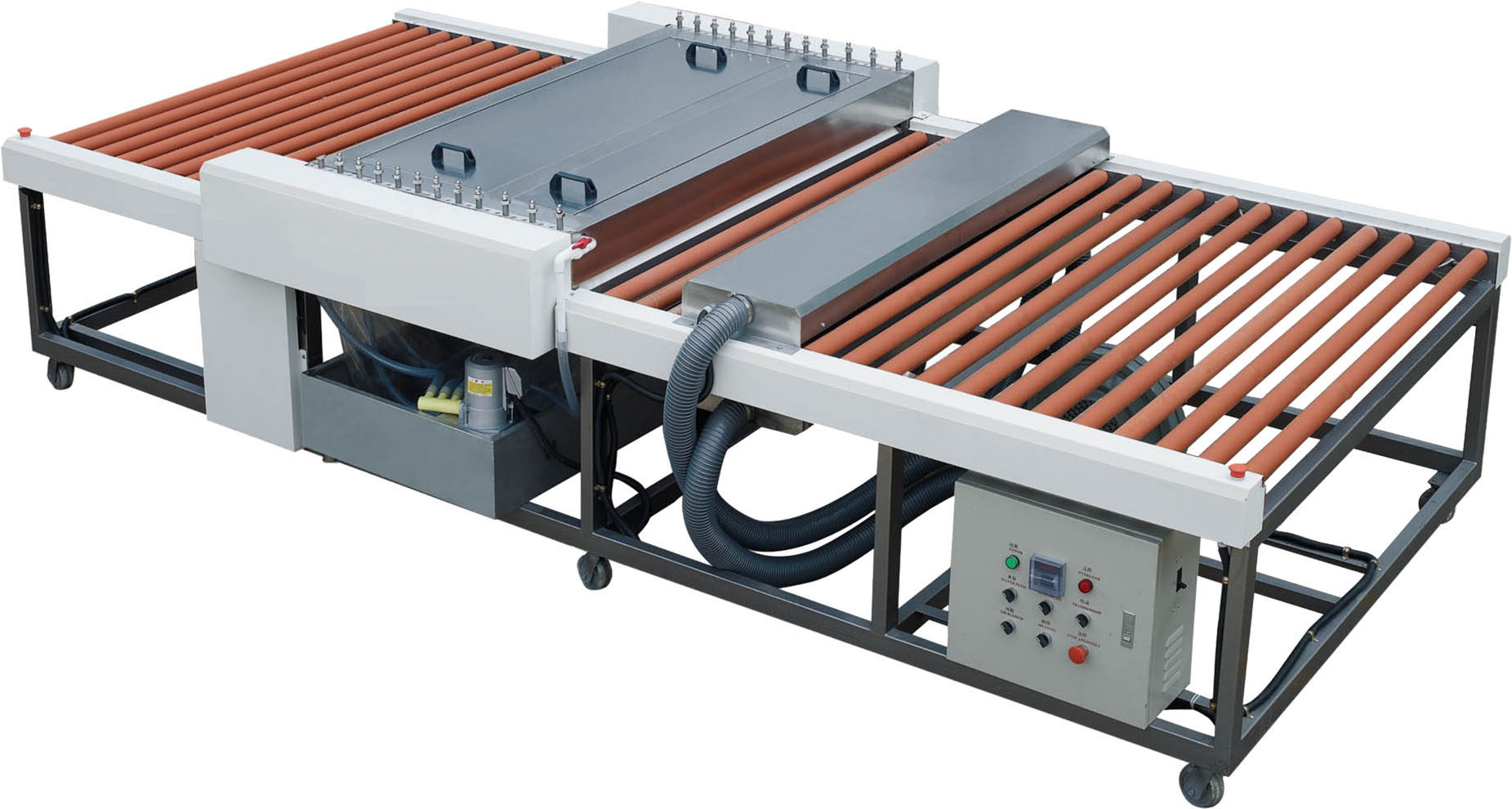

The DQX20 Glass Washing Machine (2000mm) represents the pinnacle of efficiency and automation within the glass processing industry. Engineered for the precise handling of flat glass, this Automatic glass washer serves as a critical piece of Flat glass washing and drying equipment for facilities demanding high-performance cleaning and drying capabilities within a streamlined, user-friendly package. Designed to process glass sheets up to 2000mm in width, the DQX20 is suitable for diverse industrial and commercial applications requiring reliable and efficient glass preparation. Its core function as a dedicated Flat glass washing machine ensures optimal care and results for flat glass surfaces.

Product Features

1. Advanced Automation & Control:

As a sophisticated Automatic glass washer, the DQX20 integrates cutting-edge automation technology. This simplifies operation, guarantees consistent performance, and minimizes manual intervention, making it ideal for high-volume production lines. The machine features an intuitive user interface allowing operators precise control over parameters like washing speed, brush pressure, and drying intensity. Integrated safety systems, including emergency stops and alarms, ensure a secure operating environment.

2. Optimized Flat Glass Processing:

Designed explicitly as a Flat glass washer, the DQX20's configuration ensures thorough and uniform cleaning across the entire surface of flat glass panels. Its horizontal layout facilitates straightforward loading and unloading, optimizing workflow efficiency and significantly reducing manual handling requirements and associated risks. The design prioritizes gentle yet effective treatment of the glass.

3. Integrated Washing & Drying System:

Functioning as comprehensive Glass washing and drying machine, the DQX20 seamlessly combines both critical functions in one integrated unit. The washing system employs multiple high-pressure spray nozzles and rotating brush rollers to effectively eliminate contaminants like dust, dirt, and grease. High-pressure sprays ensure deep cleaning, while brush rollers provide scrubbing action for stubborn residues.

4. High-Performance Drying Technology:

Following washing, the DQX20's integrated drying system, a key aspect of its Flat glass washing and drying equipment, utilizes precisely positioned air knives. These generate powerful air streams to rapidly and thoroughly blow off excess water, preventing water spots or streaks. The air knives are adjustable to accommodate different glass thicknesses and specific drying requirements.

5. Energy Efficient Design:

The DQX20 incorporates energy-saving components engineered to reduce overall power consumption while maintaining peak operational performance. This focus on efficiency directly lowers operational costs and supports environmental sustainability initiatives, making the DQX20 an eco-conscious choice for modern facilities.

Product Applications

The DQX20 Glass Washing Machine (2000mm) is engineered for demanding environments requiring pristine flat glass preparation. Its capabilities make it essential for:

- Industrial Glass Fabrication Plants: High-volume processing of flat glass for various sectors.

- Architectural Glazing Facilities: Cleaning and drying glass for windows, curtain walls, facades, and doors.

- Commercial Glass Processing Shops: Handling large-format glass for retail displays, partitions, and interior features.

- Operations Requiring Reliable Automation: Facilities prioritizing consistent results with minimal manual labor input.

- Applications Needing Wide Format Capability: Processing glass panels up to 2000mm in width efficiently.

Product Advantages

The DQX20 Flat glass washing machine delivers significant, tangible benefits:

1. Unmatched Efficiency & Throughput: Advanced automation and streamlined horizontal design enable rapid processing cycles and high-volume output, maximizing production line efficiency.

2. Exceptional Cleaning & Drying Quality: The integrated Glass washing and drying machine system guarantees consistently spotless, completely dry, and streak-free glass surfaces, ready for immediate further processing or packaging, meeting the highest quality standards.

3. Reduced Labor Costs & Enhanced Safety: Automation drastically minimizes manual intervention for washing and drying tasks. The easy-load horizontal design further reduces manual handling, lowering labor costs and significantly improving workplace safety by minimizing operator contact with solutions and wet glass and reducing lifting risks.

4. Superior Process Consistency & Reliability: Automated controls and precise engineering ensure repeatable, high-quality results batch after batch, independent of operator variability.

5. Operational Flexibility: Adjustable washing parameters (brush pressure, spray intensity) and drying settings (air knife position/force) allow the Automatic glass washer to handle a variety of glass thicknesses, contamination levels, and specific job requirements effectively.

6. Space Optimization & Workflow Integration: The horizontal Flat glass washer configuration is inherently space-efficient and facilitates smooth integration into existing production lines, optimizing material flow.

7. Lower Operational Costs & Sustainability: Energy-efficient components reduce electricity consumption, while minimized water and chemical usage (through efficient processes) and reduced glass breakage (from less handling) contribute to lower overall operating expenses and a smaller environmental footprint.

8. Wide Format Capacity: The 2000mm processing width efficiently handles large panels common in architectural and commercial applications.

Summary

The DQX20 Glass Washing Machine (2000mm) stands as a state-of-the-art Automatic glass washer and premier Flat glass washing and drying equipment. Combining advanced automation, an optimized Flat glass washer design, highly effective integrated washing and drying systems (making it a top-tier Glass washing and drying machine), and energy-efficient operation, it delivers unparalleled performance, reliability, and quality for high-volume flat glass processing. Whether the requirement is for rapid, consistent cleaning and drying of architectural panels or efficient preparation of commercial glass, the DQX20 Flat glass washing machine provides a superior, cost-effective solution that enhances productivity and product quality.

Identification data

Machine: Glass Washing Machine

Model: DQX20

Voltage and Frequency: 380V, 50Hz

Total power: 14kW

Workable thickness: 3~19mm

Weight: 1500kg

Serial No.:

Product date: 2022

Machine features

Main body dimension | 4620mm×2340mm×1140mm |

Weight | 1500kg |

Voltage | 3~AC /380V/50Hz |

Power | 14kW |

Feeding speed | 0.75~4.5m/min |

Max. Process Glass | 1950mm |

Min. Process Glass | 400x400mm |

Thickness of process glass | 3~19mm |

Main drive motor | 0.75kW |

Brush motor | 0.75kW x 1 |

Water pump | 0.55kW x 1 |

Blower motor | 1.1kW |

Heater | 11kW |