Brief introduction

DK3019 glass groove machine is used for line and curve cut and polishing in the flat glass surface. It can process 1~8 the same specification glass one time. Use the special CAM software to add the required process information, for example the type of the line, choose the process lines, etc. and generate NC code. The CNC system reads the NC code and control X, Y, Z, C four axis and spindle motor start/stop to achieve the processing requirements of pattern. After polishing, the line or curve is close to the glass body's finish

DK3019 CNC Glass Grooving Machine (3000x1900mm): Product Introduction

The DK3019 is a high-precision CNC Glass Grooving Machine engineered for demanding groove, V-groove, and engraving work on glass. This versatile Glass V groove machine and Glass Engraving Machine ensures accuracy and consistency across operations.

Key Features:

Advanced CNC Control: Delivers precision grooving, engraving, and V-grooving

Multi-Function Design: Integrates Glass Grooving Machine, V glass groover, and Glass Engraving Machine capabilities

Large Work Area: 3000x1900mm capacity accommodates diverse glass sizes

Material Versatility: Processes tempered, laminated, and coated glass

Robust Construction: High-quality spindle, tools, and stable worktable ensure durability

Primary Applications:

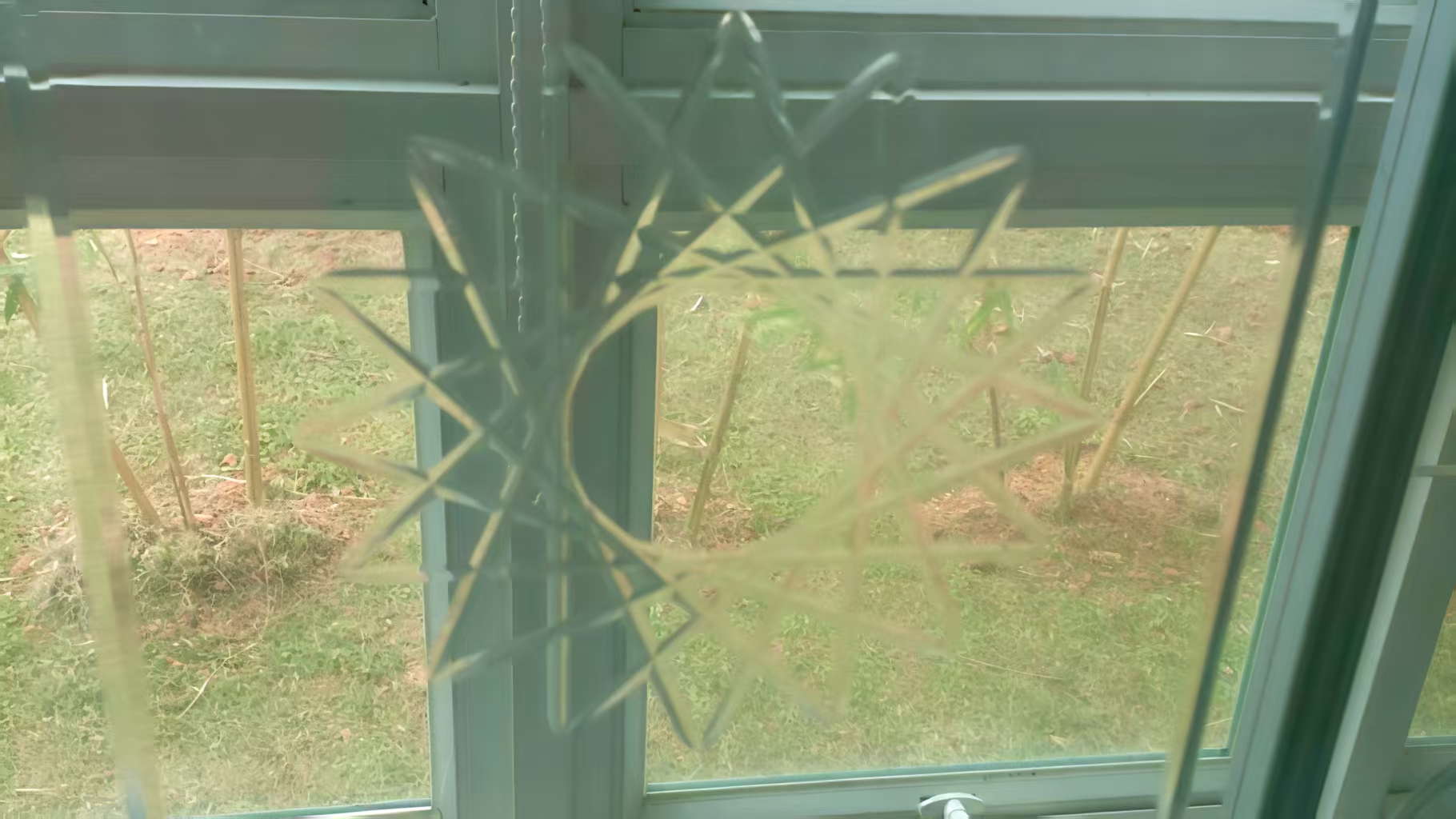

1. Precision Grooving: Creates intricate grooves for architectural glass, partitions, and decorative elements.

2. V-Groove Production: Functions as a dedicated Glass V groove machine for doors, windows, and furniture.

3. Custom Engraving: Operates as a Glass Engraving Machine for logos, patterns, and signage on decorative panels and glassware.

Key Benefits:

Superior Precision: CNC accuracy ensures exact groove dimensions and engraving detail

Enhanced Efficiency: Combines grooving, V-grooving (V glass groover), and engraving in one system

Streamlined Production: Automation reduces errors and boosts output for custom or large-scale jobs

Surface Quality: Delivers clean cuts and smooth finishes on all glass types

Design Flexibility: Handles complex patterns and custom specifications with ease

Industry Versatility: Essential for architectural, decorative, and furniture glass manufacturing

Overall: The DK3019 CNC Glass Grooving Machine (3000x1900mm) is a comprehensive solution integrating Glass Grooving Machine, Glass V groove machine, and Glass Engraving Machine functions. Its precision and large format make it indispensable for high-end glass fabrication.

Name plate

Machine’s name:CNC Glass Grooving Machine

Model: DK3019

Power Supply: 380V, 50Hz

Total power: 22.0Kw

Glass thickness: 3~40mm

Max. Glass Size: 3000x1900

Weight: 6500kg

Serial Number:

Production date: 2015

Main technical data

v Max. Processing glass size:3000×1900mm

v Processing thickness:3~40 mm

v Grooving max. width: 30mm

v Axis stroke(X,Y,Z): 3000, 1900, 200mm

v Max. Speed for X、Y、Z: 40/30/5m/min

v Max. speed for spindle:3500rpm

v Main spindle:5.2kw

v Max. Diameter for the wheel:φ170

v Tool rack:10

v Total power:22kw

v Overall size(X、Y、Z):5700×3000×2200mm

v Gross weight:6500kg

v Finished tolerance:±0.150mm