Glass, an amorphous inorganic non-metallic material, has been integral to human progress for over four millennia. Originally crafted by ancient Egyptians, it has evolved from decorative beads into a cornerstone of modern industry and architecture. Produced primarily from natural minerals such as quartz sand, soda ash, and limestone, its fundamental chemical basis is silicon dioxide—a composition that yields a versatile and durable non-crystalline solid.

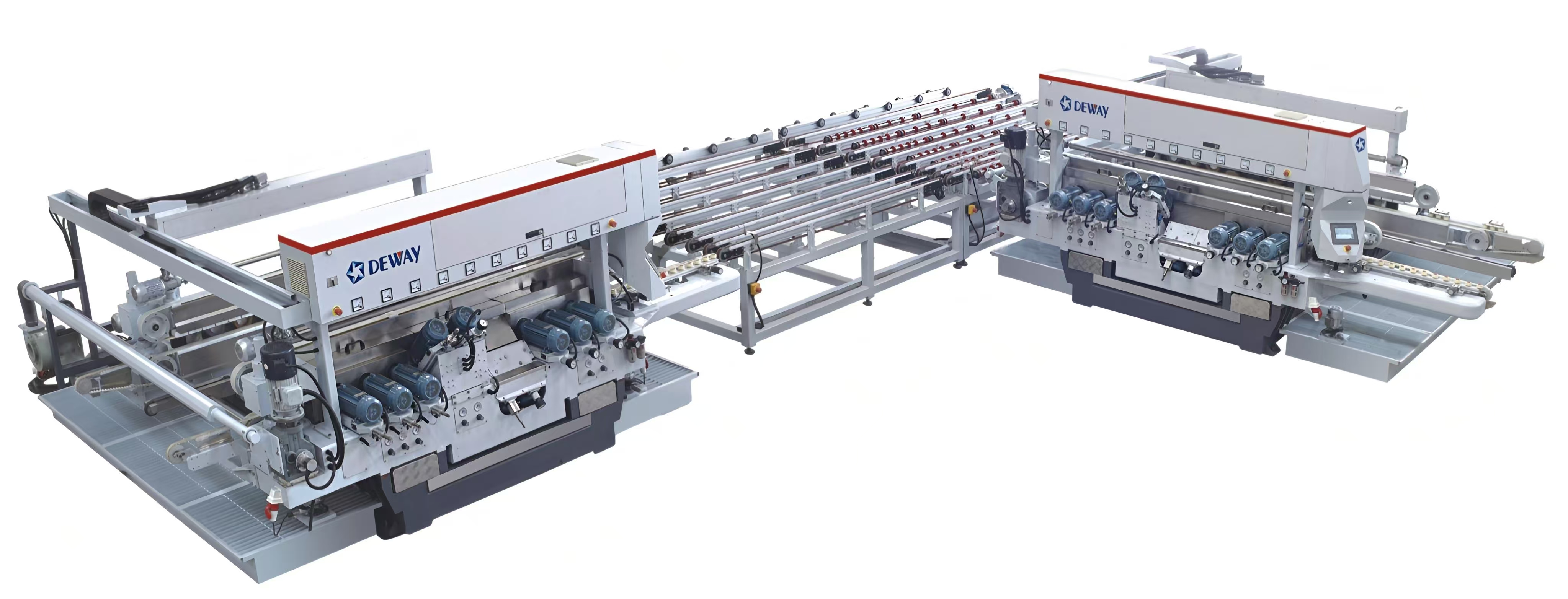

Today, glass is not only defined by its chemistry but also by the advanced techniques used to shape and enhance it. Modern glass processing machines have revolutionized production, enabling high precision, efficiency, and consistency. These technologies allow manufacturers to move beyond basic flat glass to a wide array of engineered products suitable for specialized applications.

Classification and Advanced Processing

Glass products are broadly categorized into flat glass and deep-processed glass. The latter involves secondary fabrication using specialized equipment to improve performance, safety, and aesthetics. Key processing methods include:

- Decorative & Artistic Processing: Such as hot-melt, engraved, stained, and mosaic glass.

- Functional & Safety Processing: Including tempering, laminating, coating, and insulating.

- Edge & Surface Finishing: This is where precision glass edging machine units play a critical role. For straight-line edge polishing, a glass straight-line single edging machine is commonly employed, ensuring clean, smooth, and safe edges on glass panels used in furniture, mirrors, and interior fixtures. For higher throughput on parallel edges, a glass double edging machine enables simultaneous processing of both sides, greatly improving efficiency in industrial production. When a precise angled finish is required—often for decorative effects, safety, or assembly needs—a glass straight-line bevelling machine is utilized to create consistent chamfers or bevels.

These glass processing machines form the backbone of modern glass fabrication lines, ensuring edges are not only aesthetically pleasing but also structurally sound and safe for handling.

Deep-Processing and Engineered Glass Solutions

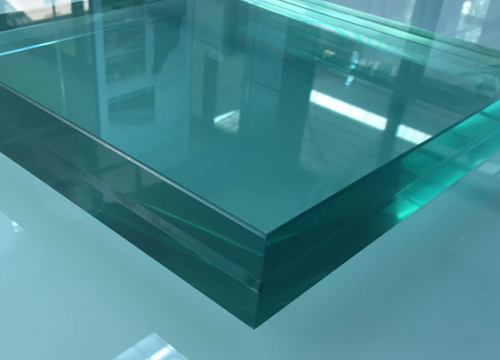

1. Laminated Glass

Created by bonding two or more glass layers with polymer interlayers under heat and pressure, laminated glass offers security, sound reduction, and UV protection. Its edges are often finished using a glass edging machine to ensure perfect fit and safety before installation in facades, skylights, or automotive windows.

2. Tempered Glass

Through thermal or chemical treatment, tempered glass gains superior strength and shatters into small, harmless granules. Prior to tempering, glass sheets are precisely cut and edged—frequently using a glass straight-line single edging machine or a glass double edging machine—to ensure dimensional accuracy and edge integrity, which is crucial for high-stress applications like building windows, shower doors, and glass balustrades.

3. Coated Glass

This category includes reflective, low-emissivity (Low-E), and conductive coatings applied to modify thermal and optical properties. Coated glass used in curtain walls or insulating units often undergoes edge finishing with a glass straight-line bevelling machine or polishing equipment to achieve the precise edge profile required for seamless sealing and assembly.

Conclusion: Precision in the Glass Age

The journey of glass—from ancient artifact to a high-tech building material—is now driven by precision engineering and advanced machinery. Equipment such as the glass straight-line single edging machine, glass double edging machine, and glass straight-line bevelling machine exemplify how modern glass processing machines enable finer control, efficiency, and quality in fabrication. As architectural and industrial demands grow, these technologies ensure glass continues to meet the highest standards of safety, sustainability, and design excellence.