In the fast-evolving landscape of glass processing, edge finishing and polishing are critical operations where quality and throughput directly impact a manufacturer's competitive edge. Faced with increasingly diverse customer specifications and tight turnaround times, conventional single-sided equipment often struggles to meet modern demands for high-volume, precision output. Enter the advanced Glass Double Edging Machine—a transformative solution that is redefining productivity standards for fabricators worldwide.

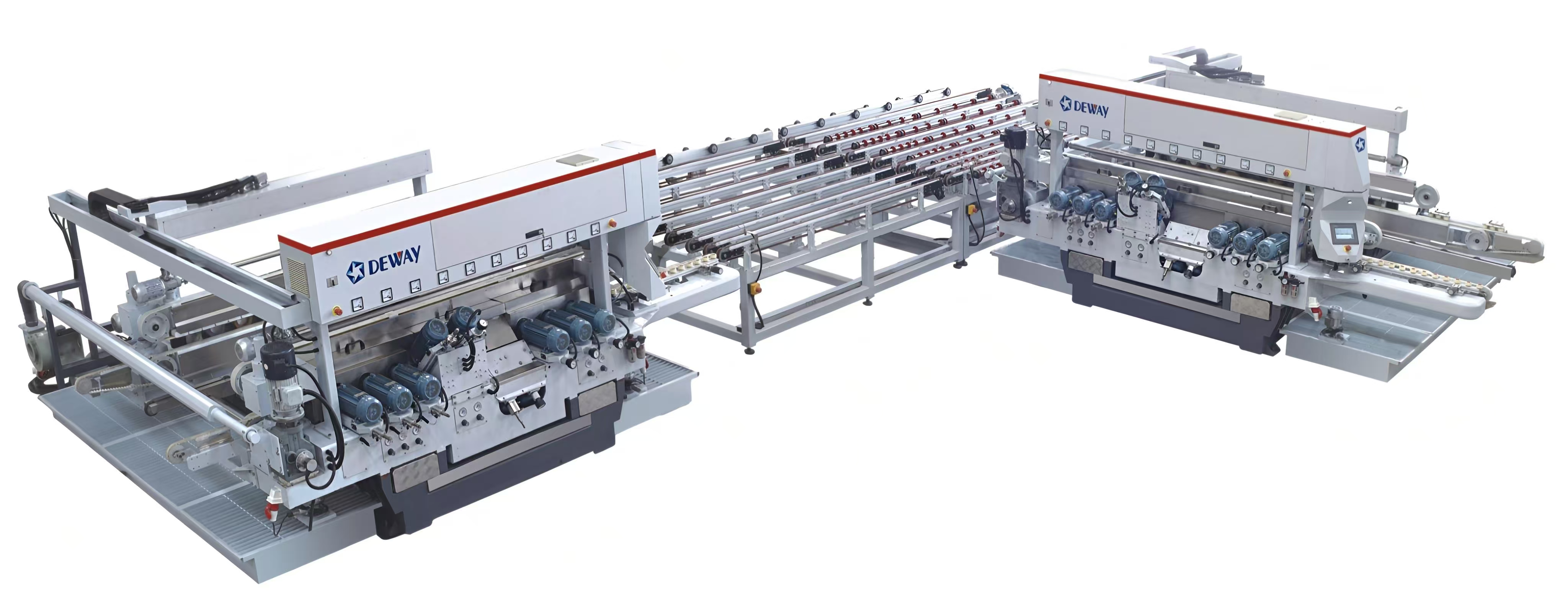

This innovative equipment, essentially a sophisticated Glass Double Sides Edging Processing Machine, enables the simultaneous grinding and polishing of two parallel edges of a glass sheet in a single pass. This core functionality represents a fundamental shift from sequential processing, delivering unparalleled gains across the entire production workflow.

Unmatched Productivity Gains

With twice the theoretical throughput of a traditional single-head machine, a Glass Double Edging Processing Machine dramatically accelerates order fulfillment. Fabricators can process large volumes faster, reducing lead times, enhancing client satisfaction, and freeing up capacity for additional orders. Leading models, such as those from Deway Glass Machinery, incorporate intelligent automation features like automatic glass size and thickness detection. This minimizes manual setup and intervention, curbing labor costs, mitigating operational errors, and ensuring the Glass Double Edging Processing Line runs at optimal, continuous productivity—directly translating to improved profitability.

Superior Finish Quality and Application Versatility

Beyond raw speed, these machines deliver exceptional finish consistency. Modern polishing technology integrated into these systems allows for the precise execution of various edge profiles—beveled, pencil, flat, and more—catering to aesthetic and functional needs across industries. Features like water-free grinding prevent surface imperfections, ensuring high clarity and precise geometries. This capability minimizes reject rates and consistently meets stringent customer expectations.

The versatility of a Glass Double Sides Edging Processing Machine is a significant advantage. It adeptly handles a broad spectrum of applications, including furniture glass (tables, shower doors, display cases), architectural glass (doors, windows, curtain walls), and automotive glass components. Its adaptive processing power makes it an invaluable asset for shops serving multiple market segments.

Enhanced Safety and Long-Term Cost Efficiency

Safety is paramount. These machines expertly eliminate dangerous sharp edges, providing a crucial safeguard for end-products. Operationally, processing two edges at once significantly reduces the need for manual handling and repositioning of glass sheets, thereby lowering the risk of workplace accidents and material breakage.

While the initial investment in a high-performance Glass Double Edging Machine is considerable, the long-term economic benefits for medium to large-scale operations are compelling. The synergy of increased throughput, reduced waste, superior quality, and operational safety drives significant cost savings per unit over time, offering a strong return on investment. Furthermore, robust construction and reliable performance, backed by comprehensive manufacturer support and training—as offered by Deway—ensure sustained value and minimal downtime.

The Future of Fabrication

As the industry moves towards smarter, more integrated manufacturing, the automated Glass Double Edging Processing Line, anchored by a capable Glass Double Edging Processing Machine, is becoming the benchmark for modern glass shops. This technology is no longer just a productivity tool but a foundational element for building a resilient, efficient, and competitive fabrication business poised to meet future challenges.