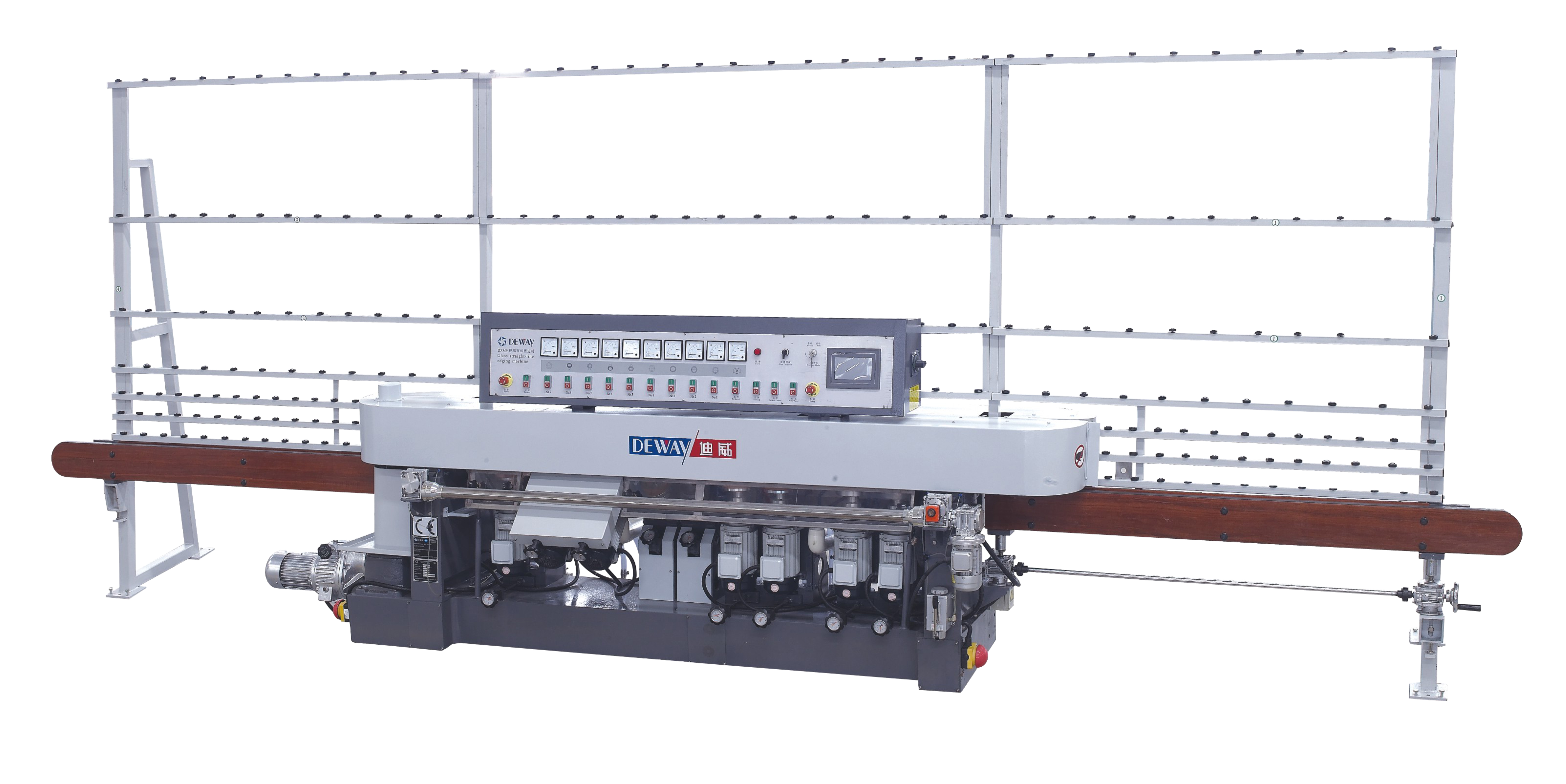

With the continuous operation of edging equipment, mechanical wear, inadequate maintenance, and other factors often lead to various problems in glass processing. Based on practical experience, here is an overview of common issues and their solutions.

1. Tapered Edges (One End Larger Than the Other)

After a period of use, the machine may become unlevel, resulting in tapered glass pieces. The main causes include:

Soft Foundation: An uncompacted concrete foundation may sink under the machine's weight, causing imbalance. The solution is to reinforce the foundation and level the machine body.

Unstable Glass Support Feet: During the processing of large glass, unsecured supports can shift, affecting levelness. Recalibrating the supports is necessary.

Unstable Conveyor Chain Clamping: Over time, only partially replacing the square rubber blocks on the conveyor chain can create height differences between old and new blocks, leading to tapered edges. It is recommended to replace all square rubber blocks or the entire conveyor chain.

Conveyor Chain Misalignment: If the chains at the infeed and outfeed ends are not aligned (level) with the front and rear press plates, adjustment is required.

For the infeed end, adjust the guide rail height (via the travel screw underneath) so that a 2500mm long glass remains flat on the chain throughout the process. Observe two points when the glass has entered about 40cm past the press plate: whether the glass under the press plate and the glass on the right-side chain are still fully seated. If the glass lifts off the chain under the press plate, lower the guide rail adjustment screw on the right-side A-frame. If the tail of the glass on the right-side chain lifts, raise the same screw. The same principle applies to leveling the left-side conveyor chain.

2. Incomplete Polishing at Ends or Center

Ends Not Polished: This is often caused by displaced sprockets on the infeed-end chain assembly, leading to glass shifting during advancement. Open both side covers and realign the sprockets at the outfeed end to match the height and angle of the two sprockets on the gearbox.

Center Not Polished or Poor Polishing: Loose front and rear press plates can cause the glass to sag during grinding, resulting in excessive material removal at the center. This leads to inadequate polishing in the middle section. The solution is to open the machine cover and tighten the press plate chain.

Regular maintenance and timely adjustment of the Glass Straight Line Edging Machine are crucial for ensuring consistent output quality. Proper operation of the Glass Edging Machine and Glass Grinding Machine components directly affects edge accuracy, while optimal performance of the Glass Polishing Machine or Glass Single Edging Polisher is essential for achieving a high-quality finish. Addressing these common issues proactively helps maintain the efficiency and precision of the glass processing line.