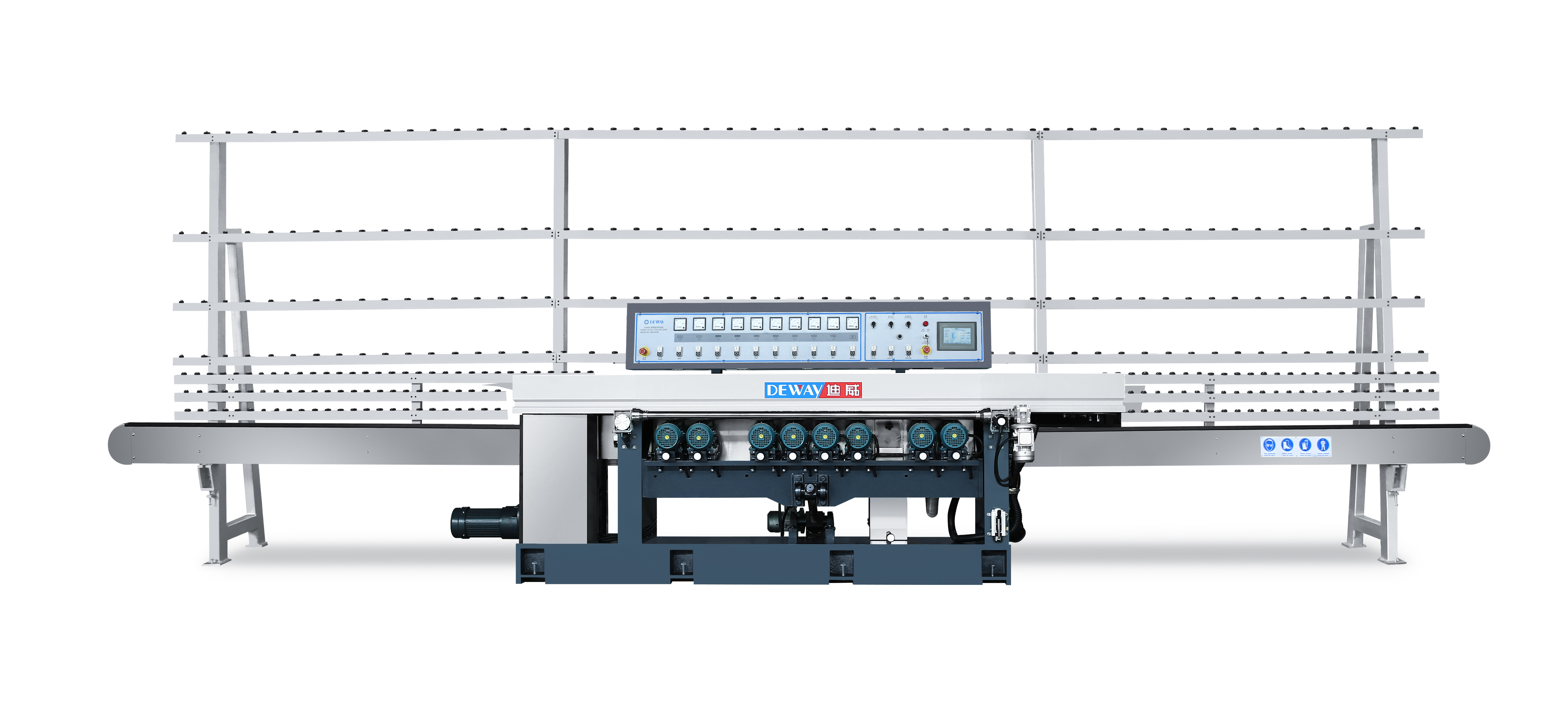

Product Introduction: DXM251 Glass Beveling Machine (8 Spindles)

The DXM251 Glass Beveling Machine (8 spindles) is a state-of-the-art Glass Straight-line Bevel Machine engineered for precision glass processing. This advanced solution delivers high-quality beveling on flat glass surfaces, ensuring unparalleled accuracy and efficiency. Essential for glass industry manufacturers, it serves applications including architectural glass, decorative mirrors, and glass furniture.

---

Product Features

1. Multi-Spindle Configuration:

Equipped with 8 strategically positioned spindles working in unison to provide smooth, consistent finishes, reducing polishing requirements and material waste.

2. Precision Control Systems:

As a Precision Glass Beveling Machine, it features advanced controls for exact adjustments to bevel angle and depth, ensuring each piece meets specifications.

3. Robust Construction:

Built with high-strength materials for durability and operational stability, engineered to withstand continuous industrial use.

4. Automated Digital Interface:

User-friendly digital controls enable rapid parameter setup/modification, reducing manual labor and minimizing human error.

5. Safety Integration:

Includes emergency stop buttons and protective covers to ensure operator safety in high-volume environments.

6. Modular Maintenance Design:

Easily accessible components facilitate quick inspections and replacements, minimizing downtime.

---

Product Applications

This Versatile Glass Beveling System accommodates diverse requirements:

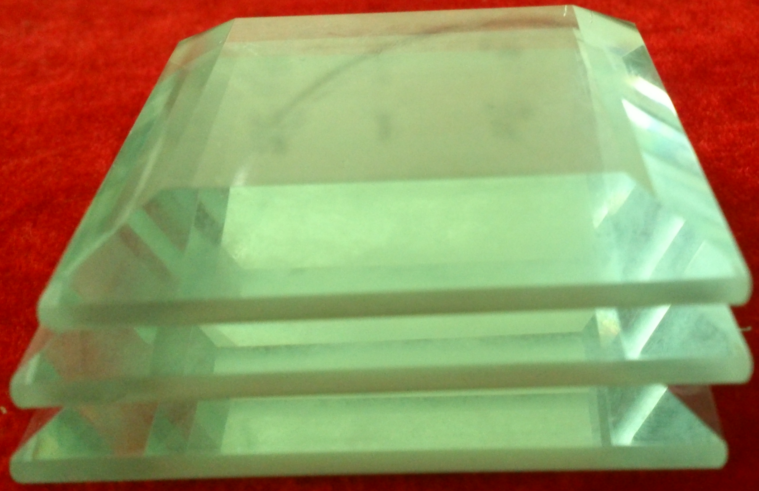

Architectural Glass: Precision beveling for structural and facade elements.

Decorative Mirrors: High-quality edge finishing for residential/commercial mirrors.

Glass Furniture: Accurate beveling for tabletops, shelves, and decorative elements.

Thin Decorative Panels: Delicate beveling for artistic installations.

Thick Structural Glass: Processing heavy glass for load-bearing applications.

---

Product Advantages

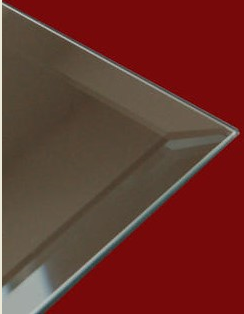

1. Uncompromised Precision:

As a Precision Glass Beveling Machine, it guarantees exact bevel angles/depth adherence to specifications, eliminating rework.

2. High-Volume Efficiency:

The Multi-Spindle Glass Beveling Machine design enables simultaneous multi-edge processing, significantly boosting productivity and throughput.

3. Material & Cost Savings:

Consistent spindle performance minimizes glass waste and reduces secondary polishing requirements, lowering operational costs.

4. Industrial Durability:

Heavy-duty construction ensures long-term reliability with minimal maintenance interruptions, maximizing ROI.

5. Adaptive Processing Capability:

This Versatile Glass Beveling System handles all glass thicknesses (thin decorative to thick structural) and sizes without performance compromise.

6. Operator Safety & Ease:

Integrated safety mechanisms (emergency stops, protective covers) and intuitive controls ensure secure, efficient operation.

7. Streamlined Maintenance:

Modular design allows rapid component access, reducing service downtime and sustaining optimal performance.

---

Conclusion

The DXM251 Glass Beveling Machine (8 spindles) exemplifies advanced glass processing technology. Its core identity as a Glass Straight-line Bevel Machine is enhanced by critical capabilities: unparalleled accuracy as a Precision Glass Beveling Machine, high-throughput functionality as a Multi-Spindle Glass Beveling Machine, and adaptable performance as a Versatile Glass Beveling System. This synergy delivers exceptional efficiency, durability, and finish quality across architectural glass, mirrors, and furniture applications. By combining precision engineering with operational safety and ease of maintenance, this Glass Beveling Machine provides an indispensable solution for manufacturers seeking to optimize quality, productivity, and cost-efficiency in beveled glass production.

Identification data

Machine: Glass beveling

Model: DXM251

Voltage and Frequency: 380V, 50Hz

Total power: 18.9Kw

Workable thickness: 3~19mm

Weight: 4000kg

Serial no.:

Product date: 2016

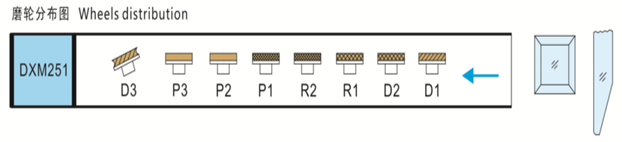

Wheel position with respect to the incoming sheet | ||||||||

DXM251 | ||||||||

Ref.no | No8 | No7 | No6 | No5 | No4 | No3 | No2 | No1 |

Motor | 1.5kW | 1.5kW | 1.5kW | 2.2kW | 2.2kW | 2.2kW | 2.2kW | 2.2kW |

Rev.(50Hz) | 2840 | 1400 | 1400 | 2840 | 2840 | 2840 | 2840 | 2840 |

Rev.(60Hz) | 3400 | 1680 | 1680 | 3400 | 3400 | 3400 | 3400 | 3400 |

Name | Rounding wheel | Wool wheel | Wool wheel | Resin wheel | Resin wheel | Resin wheel | Diamond wheel | Diamond wheel |

Specification | 150×50 240 mesh | 150×22 Wool | 150×22 Wool | 150×22 10S40 | 150×22 500 mesh | 150×22 240 mesh | 150×22 180 mesh | 150×22 100 mesh |

Usage | Bottom Grinding | Beveling polishing | Beveling polishing | Beveling fine grinding | Beveling fine grinding | Beveling fine grinding | Beveling fine grinding | Beveling rough grinding |

Machine model | DXM 251 | ||

Processing (m/min) | 0.73~3.65 | ||

Min. processing glass size (mm) | 120*120 | ||

Glass thickness a | 3~19mm | ||

Remain thickness b | ≥1.5 | ||

Width Of bevel Bmax | 40mm | ||

Angle of bevel θ |

| 3°~30° |

|

Machine overall: L×B×H(mm) | 7250×1300×2500 | ||

Dimension for main machine L1×B1×H1(mm) | 4866×1225×1500 | ||

Base dimension L2×B2(mm) | 3160×650 | ||

Length of infeeding track L3 | 6980 | ||

Net weight of main machine(kg) | 4500 | ||

Total Power(kw) | 21.1 | ||